EXHIBIT 99.1

| hardie news

From appearance to performance, Linea® Weatherboards set the tone at the

Boatshed

New Zealand designer David Scott holds a special place in the Linea®

Weatherboard success story: his Boatshed boutique hotel was the first project

to be clad with the revolutionary new product. Full story page 4

March 2003 / Volume 3 Issue 1 / www.jameshardie.com 1

Linea® combines R&D, technology and performance to grow the market for

weatherboards

Three key factors in James Hardie’s high growth performance are its proprietary

technology, investment in Research & Development, and the differentiated

products that result from these.

Rapidly increasing sales of Linea® Weatherboards in New Zealand provide

striking evidence of just how effective this combination can be.

The 16mm thick boards use ceramic-based low-density (CLD) technology developed

by James Hardie to create a weatherboard that is lighter and easier to handle

than products with a similar thickness. Linea® Weatherboards are also

dimensionally stable, so they will not swell or shrink and can’t twist or rot.

Builders can choose from two widths, 135mm and 180mm, and have the option of a

horizontally-reeded surface finish with the wider board. James Hardie’s CLD

technology has also been used to create complementary fascia, barge and trim

products, resulting in the first complete James Hardie external cladding offer.

When they were launched in 2002, Linea® Weatherboards were hailed by the New

Zealand building industry as the biggest breakthrough in product development

for 20 years.

Since then, the enthusiasm has translated directly into sales, providing James

Hardie in New Zealand with its first weatherboard market growth in eight years.

Continued on page 14

|

| The future looks strong for James Hardie While this issue of HardieNews covers our third quarter results in detail, by the time you read this, we will be approaching the end of our full year. At the time of our Q3 results announcement, we predicted that our strong results would continue for the balance of the year. We continue to grow much faster in North America than the broader building and construction industry and, as sales of our differentiated products increase, our margins are expanding. We continue to gain market share in the southern and northern regions of the United States and in Canada, and in both exterior and interior product categories. Sales of differentiated, higher-priced products such as trim, soffits, panels and backerboard grew by more than 50% and sales of our new ColorPlus™ Collection of pre-painted siding more than trebled in the third quarter. In Asia Pacific, the Australian and New Zealand businesses are generating higher sales and achieving lower costs, further expanding our margins. Shareholders can look forward to a solid fourth quarter and full year. Despite major geo/political issues in the world, James Hardie should continue to grow into the next fiscal year. Our core businesses in the USA have strong growth momentum which enables us to be optimistic about our prospects even if the economy slows down. We will continue to grow in siding, with our trim and ColorPlus™ Collection products showing very good levels of growth. Our interior product, Hardibacker®, will also continue strong penetration against other cement boards as well as challenging wood and gypsum-based products where wet area use is contemplated. We will also continue to develop and roll out new products and enter new geographies. Next year will see the first sales of our new roofing product and we will launch other products targeting new market segments. All in all, it is a very exciting time to be involved with James Hardie! “The quarterly results from our major businesses are again unambiguously positive and the outlook for the balance of the year is equally encouraging.” |

| Peter Macdonald, CEO, James Hardie |

| 3rd Quarter and Year To Date at a Glance |

| US$million Q3FY03 Q3FY02 %+\(-) Net Sales $197.4 $144.8 36 Gross Profit 74.5 49.2 51 EBIT (Operating Profit) 29.9 14.2 111 |

| before restructuring and other operating expenses Restructuring and other 1.0 (17.1) (106) operating income (expenses) EBIT (Operating Profit/(loss) 30.9 (2.9) – Operating Profit (Income/(loss) 15.5 (0.4) – from continuing operations Net Operating Profit (Net Income) 15.5 4.6 237 including discontinued operations |

| 1 > HardieNews |

| results WORLD Third Quarter Results >3rd Quarter Operating Profit US$15.5 million >USA Fibre Cement EBIT* up 73% in Q3 and 58% YTD James Hardie announced an operating profit from continuing operations of US$15.5 million for the three months ended 31 December 2002. Overall, third quarter sales revenue increased 36%, gross profit was up 51% and EBIT* more than doubled to US$29.9 million. The USA Fibre Cement business was again the standout performer for the quarter, lifting sales revenue 43% and EBIT* 73%, compared to same period a year ago. EBIT increased 39% in Australia and 43% in New Zealand. |

| YTDFY03 YTDFY02 %+\(-) $605.2 $448.9 35 222.0 150.8 47 102.2 54.4 88 1.0 (28.2) (104) 103.2 26.2 294 62.0 13.7 353 116.0 14.1 – |

| * EBIT before restructuring and other operating expenses. The third quarter results maintained the strong growth momentum evident in the first half and more than offset the impact of normal seasonal industry slowdowns in our major markets. The operating profit, while well above the same period last year, would have been higher but for an after-tax charge of about US$6.5 million announced in December that arose from the early retirement of debt. For the nine months year to date, operating profit from continuing operations is up from US$13.7 million to US$62.0 million. The nine months bottom line profit increased from US$14.1 million to US$116.0 million and includes a US$54.0 million profit primarily due to the sale of our Gypsum operations in April 2002. |

| USA Fibre Cement Continued Strong Growth Sales revenue increased 43% to US$146.3 million in the 3rd quarter due to a 31% increase in sales volume to 298.2 million square feet and a 9% increase in the average selling price to US$491 per thousand square feet. Growth in demand for James Hardie’s fibre cement products continued to significantly outstrip growth in housing construction, which remained at high levels during the quarter. Results for the business were further boosted by sales from the Cemplank operations that were acquired in December 2001. Further market share gains were achieved in the northern and southern regions of the country and for exterior and interior products. The significant increase in the average selling price was due to a further increase in sales of higher-priced, differentiated products, higher product prices generally, an increase in sales of primed, exterior products in the southern markets and the reversal of a sales rebate accrual. Strong volume and revenue growth, combined with a lower cost of sales, lifted EBIT* 73% to US$37.8 million for the quarter and the EBIT margin also increased, to 25.8%. For the nine months, revenue was up 38% to US$453.5 million and EBIT* was 58% higher to US$117.3 million. The EBIT margin for the nine months was 25.9%. Australia Higher Sales, Volumes and EBIT Sales revenue increased 17% to US$31.7 million for the quarter due to a 13% lift in sales volume and a favourable exchange difference. EBIT was up 39% to US$6.1 million for the quarter and 51% to US$19.9 million for the nine months primarily due to the higher volumes and a lower unit cost of sales, partly offset for the nine months by higher SG&A costs. The EBIT margin improved to 19.2% for the quarter and 21.4% for the nine months. New Zealand Higher Sales, Volumes and EBIT Sales revenue was up 30% for the quarter due to a 17% increase in sales volumes and a favourable exchange difference, partly offset by slightly lower average selling prices. The increase in revenue together with lower unit cost of sales lifted EBIT 43% to US$2.0 million for the quarter and 44% to US$5.6 million for the nine months. The EBIT margin improved to 15.3% for the quarter and 14.2% for the nine months. |

| 2 > HardieNews

|

| world results Share Price Performance share price (A$) 7.00 6.00 5.00 4.00 3.00 2.00 1.00 0.00 Jan 02 Mar 02 May 02 Jul 02 Sep 02 Nov 02 Jan 03 Mar 03 |

| Philippines

Stronger Domestic Demand

The business recorded a small operating loss for the quarter due to supply

issues in the first half of the quarter and lower than expected export sales.

Domestic demand was stronger in the quarter lifting volumes 60%.

Chile

Strong Revenue and Volume growth

Both revenue and volumes were up significantly for the quarter as the business

continued to penetrate its targeted market segments. The entry by James Hardie

into the Chilean market has intensified competition and during the quarter

another competitor exited the market, the second to do so since the company

commenced operations in Chile in March 2001.

USA FRC Pipes

Sales Growth and Efficiency Gains

Sales of larger diameter pipes (30” to 36”) grew considerably during the

quarter helping sales revenue to almost double and sales volume to more than

double compared to the same quarter last year. Unit production costs have

continued to decline as significant improvements in manufacturing efficiencies

are being achieved.

Outlook

In North America, current indicators of housing activity remain positive with

increases in both starts and permits in recent months. Additionally, we expect

to continue to win market share across our product range and in both the north

and south of the country.

We expect to make further inroads into the large vinyl siding market in the

north as awareness continues to increase among the region’s builders,

distributors and homeowners.

In the south, we expect further strong growth in the region, fuelled by an

increased focus on the repair and remodel segment and increased selling

activity in rural areas.

In Australia, recent signs of softer demand are expected to continue in the

fourth quarter but the renovations and commercial segments are expected to

remain buoyant. The business expects a strong 4th quarter with further top line

growth and a continuation of lower costs driving solid returns.

In New Zealand, demand is expected to remain strong in line with continued

growth in the residential building market. Revenue and profitability is

expected to lift in the 4th quarter compared to the previous year as a result

of increased sales volumes and further manufacturing cost savings.

In the Philippines, continued strong growth in domestic sales is expected as

the business continues to penetrate against plywood. Improved manufacturing

performance at the Philippines plant is expected to result in increased export

sales and help the business improve profitability.

In Chile, further market penetration and share growth is expected as awareness

of the company’s expanded product range continues to grow.

The US-based FRC Pipes business is continuing to increase production to meet

growing demand, and we expect further growth in sales, as well as improvements

in operating efficiency.

Overall, the strong growth momentum evident in the first nine months is

continuing into the fourth quarter and there is no sign of any near-term threat

to highly satisfactory results overall for the full year.

3 > HardieNews

|

| NEW ZEALAND From appearance to performance, Linea® Weatherboards set the tone at the Boatshed At first glance, the Boatshed on Waiheke Island, 30 minutes from Auckland, looks like a cluster of buildings that might occur in any old, small beach-side community in New Zealand. It’s an effect that has been carefully planned and executed by designer David Scott, with the help of James Hardie’s Linea® Weatherboards and Linea® Trim. One end of the site features three boatsheds containing guest suites. At the other end, the ground floor is occupied by a commercially-equipped kitchen where guests can meet. Above this area, “The Bridge” offers a suite with panoramic views above the beach. Connecting this group of buildings is the central pavilion, which provides dining and lounge areas for all guests, and entry to the three-storey lighthouse suite. Unbelievably authentic David Scott chose Linea® Weatherboards for the external walls of all the buildings, for their “appearance, and their performance. I liked the fact that they are so thick,” he said. “They look unbelievably authentic!” The weatherboards have also been used in some internal areas, to achieve specific design objectives. The central pavilion, which acts as a linking space, has been decorated in an “outdoor” style that complements the resort and has Linea® Weatherboards inside and out. “Whether you are inside, or out, you have the feeling that you are looking at a beachside building,” said David. Inside the boatshed suites, Linea® Weatherboards clad the outside wall of the bathrooms, recalling an earlier time when bathrooms were outside. David Scott’s good experience of Linea® Weatherboards led him to discover other James Hardie products, which he then used extensively at the Boatshed. These include HardiGroove™ Sheets, which give ceilings and dado-height wall panels the appearance of tongue and groove panelling; smooth Villaboard™ Lining sheets fixed to interior walls, covered with glass-fibre fabric and painted to create the woven fabric appearance of canvas; and smooth sheets and specially-cut fibre cement battens used to create the strong vertical lines of the central lighthouse structure. One look at the location of the boatshed is enough to explain David’s enthusiasm for the James Hardie products. “The buildings are 50 metres off the high water mark and they face due north, so they can take a pounding from the sun and sea,” said David. Unaffected by the environment “Linea® Weatherboards are unaffected by this environment, so there is no shifting or movement in the buildings, and very little maintenance required. Timber planks would be moving all over the place! “Inside, the fibre cement sheets we used have created acoustically separated walls that allow us to meet the very rigid guidelines we set for reduced noise transmission throughout the buildings. In some places, these dual frame separating walls also gave us the necessary fire-rated boundary walls.” |

| To see more of this Linea® development, visit www.boatshed.co.nz

Boatshed photos on cover and this page from Trends Publishing International. Photographer: Kallan MacLeod

4 > HardieNews

|

| UNITED STATES

NBC spot puts James Hardie in the spotlight

James Hardie grabbed the national spotlight when it was featured on the March 5

edition of NBC’s Today Show, watched by more than 6.6 million consumers.

Pointing out that curb appeal and the right siding can increase a home’s value,

presenter Al Roker asked show home remodelling expert, Lou Manfredini, to show

viewers their siding options. He quickly summed up how unique James Hardie’s

formulation and design are when he said,

“This is awesome! It offers the maintenance-free qualities of vinyl, the look

of real wood, but it won’t warp, rot or burn”.

Introducing the segment, the Today Show reported that over 44 million

remodelling projects were completed in the USA last year. The United States

National Association of the Remodelling Industry calculates that almost 30

percent were exterior improvements.

To see what Lou Manfredini had to say about James Hardie, visit

www.jameshardie.com and follow the link on the siding home page.

UNITED STATES

Emotional brand material gives builders something more to work with

A new television commercial is helping to convince Americans that a house is

not a home without James Hardie siding.

James Hardie has expanded its co-branding program by adding a television

commercial to the package of local newspaper and regional magazine

advertisements it offers builders to promote themselves in their communities.

The commercial is airing on the cable show, Home & Garden Television, where it

will reach 56 million households, or over 43 million viewers aged between

35-64. Builders can choose a 25 or 40 second version of the commercial, then

tag on a 5 or 20 second message with information for their communities. While

the primary market for the commercial is in the north, it is also being used in

the south.

John Dybsky, Marketing Manager for James Hardie in the USA, explained the

rationale behind the new campaign: “Co-branding with builders throughout the

north is our core strategy, so we wanted a creative format that builders would

embrace. That’s why we decided on a brand-positioned message rather than a

product-focused one.”

The new commercial shows a little girl using a crayon to transfer the colour

and texture of her home’s siding onto a sheet of paper. The camera then follows

her inside, where she cuts the sheet into strips and applies these as siding to

her doll’s house.

“The commercial had to have a compelling visual message that builders would

relate to,” said John Dybsky. “At the same time, it needed to reinforce the

value proposition of our brand, whose benefits are directly linked to

consumers’ emotional attachment to their homes.

The little girl’s passionate pursuit of textured siding for her doll’s house

does the job beautifully.”

Early indications are that builders – and consumers –have embraced the message.

James Hardie has recorded a 38% increase in web site hits since the Home &

Garden commercial started screening.

Overall, the co-branded advertising campaign has increased advertising

impressions (calculated as the total number of readers who see each magazine)

from 14 million in 2001 to over 32 million in 2002.

5 > HardieNews

|

| UNITED STATES

Website gives visitors a brand new image

James Hardie has redesigned its North American web site to deliver a consistent

brand image, and comprehensive information tailored to visitors’ needs

Visitors to the North American web site, www.jameshardie.com will now find

light, attractive pages created using the emotional lifestyle and product

images that have been so successful in the business’s marketing and advertising

campaigns.

Redevelopment of the site has been managed by Matt Roth, Marketing Manager for

James Hardie Building Products. “The new design was created with two key

objectives,” he said.

“We wanted to significantly improve navigation, and improve visual appeal with

links back to our national brand campaign.

“When we launched the site three years ago, we had about 20,000 hits (or

visits) a month,” explained Matt. “Now, it’s 120,000 a month, so the site has

tremendous power to reinforce our messages.”

Using the site’s revised navigation, visitors to the home page can search the

site by product, country or individual need, choosing between

Homeowner/Realtor, Builder, Remodeller, Dealer, Architect and Media.

The next phase of the web site will include the addition of James Hardie Europe

and the redesign of James Hardie North American Pipes to a more global brand

image.

WORLD

Changes to the James Hardie Group Management Team will improve the way we

manage our major businesses, and our biggest growth opportunities.

Restructured for global growth

New roles for three members of James Hardie’s Group Management Team will see

the company manage its business globally.

Louis Gries, Executive Vice President Americas, has been appointed Executive

Vice President Operations, responsible for all James Hardie operations in the

Americas and Asia Pacific. He also has specific responsibility for sales and

marketing, and business development in Europe.

Don Merkley, Executive Vice President R&D, now has an expanded role,

responsible for our FRC Pipes business in Australia and the USA, as well as our

emerging Roofing business in the USA. Long-term, there is the potential for

both FRC Pipes and the emerging Roofing business to be expanded into other

countries.

Dave Merkley, Executive Vice President Manufacturing/ Engineering, continues to

be responsible for global manufacturing and engineering, but his role has

increased emphasis in countries outside the USA.

Announcing the changes, James Hardie CEO, Peter Macdonald, said: “The company’s

focus on rapid growth, including geographic expansion, means that our business

is becoming more global in nature and we are convinced that we can best manage

key areas globally.

“We have already seen significant benefits from managing R&D and Manufacturing

globally. These changes will help us support this focus and build our position

as the world’s best at inventing, manufacturing and selling innovative building

products.

“A global approach will also help us identify employees who have the potential

to be part of our next generation of management and who can help us capitalise

on our many growth opportunities in existing and new geographies,” explained

Peter Macdonald.

“We need to make sure that we have the organisational capability to achieve the

ambitious agenda we have set to build new businesses, launch new products and

expand the company.”

6 > HardieNews

|

| ASIA PACIFIC

Fiesta approach encourages many hands to help wash-up

Photographed during the wash-up fiesta were (L to R) Christine Borromeo

(Finance), Heidi Bulosan (Finance), Helen Ramilo (Office of the President) and

Mizle Navea (Logistics)

At first glance, wash-up and fiesta appear to describe activities that

contradict each other. James Hardie Philippines has found a way to unite them

to and provide a positive way of doing things.

Within James Hardie, a wash-up involves dismantling production machinery,

cleaning it out and then putting it back together. Fiesta retains its

traditional meaning of a celebration, holiday or special event.

Late last year, the new Vice President for Manufacturing in the Philippines,

Danny De Guzman, found a way to combine the words – and the activities – when

he involved other departments of the business in Manufacturing’s wash-up.

Wearing wash-up clothes and personal protective equipment, and fully focussed

on job safety, groups from Logistics, Finance, Human Resources, IS, Customer

Service and the Office of the President came in to shovel and hose down under

the machine for more than an hour.

“My main goal was involvement,” explained Danny De Guzman. “It’s good to see

admin people talk to people in the factory, asking what else can they do, where

they can clean, where they can find bins and the like.

“It’s one way to socialise and meet people across departments. It also helps

people in other departments to fully-understand the job done by Manufacturing,

and show they support it. This in turn increases productivity!”

AUSTRALIA

With help from James Hardie PrimeLine™ Newport Weatherboards, the

Canberra-based Smart Housing Company has captured traditional American

architectural charm in its latest display home.

Traditional design brings America’s New England to Canberra

Since its official opening at the end of last year, The Smart Housing Company’s

latest display home, The Boston, has attracted a lot of attention.

Peter Kinnane from The Smart Housing Company says that he and his partner, Tim

Maloney, are always looking for new things to offer customers and the

PrimeLine™ Newport provided this, with its ability to create a traditional

style of home.

The home was designed by Jamie Farrelly from Urban Design and built by The

Smart Housing Company.

Its appearance – and name – were inspired by the prestigious New England region

in America. In keeping with this, the home features expensive fittings and

features throughout.

The attention to detail and quality that led The Smart Housing Company to build

with the PrimeLine™ Newport Weatherboards is evident in features such as the

specially-quarried granite bluestone used to clad the foundations and chimney,

the timber picket fence – even the roses laid out in formal garden beds.

The Smart Housing Company builds about 20 custom homes a year in the Australian

Capital Territory, and has twice won prestigious National Master Builder’s

Awards.

7 > HardieNews

|

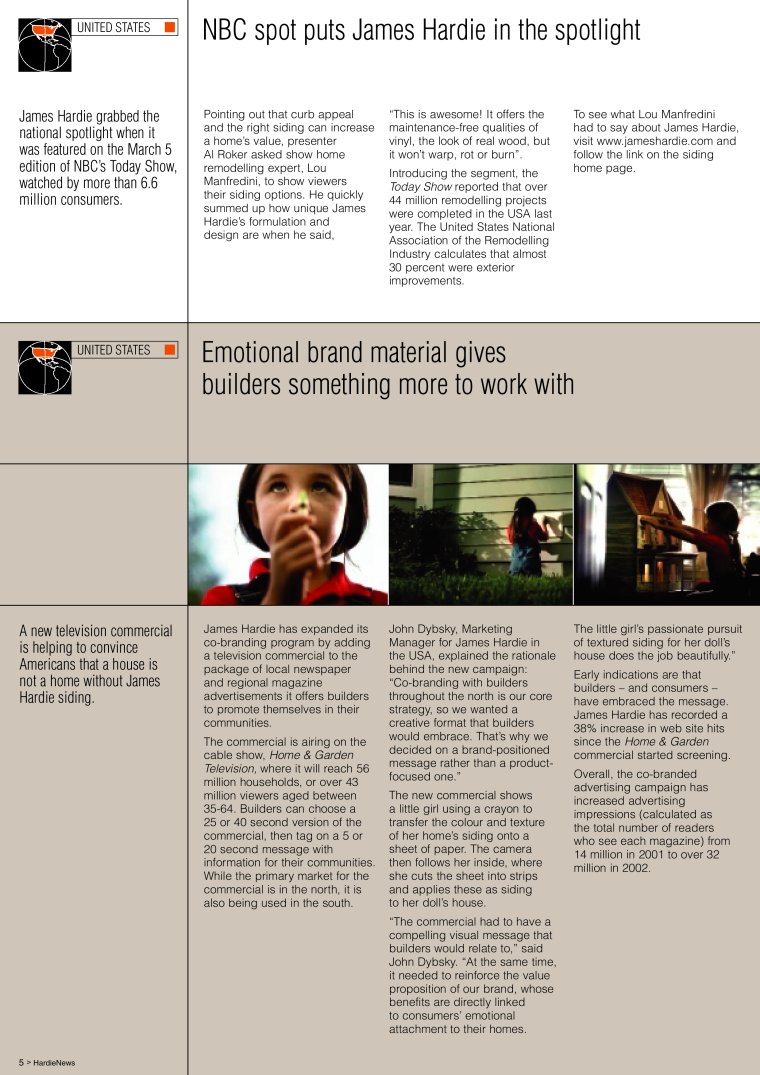

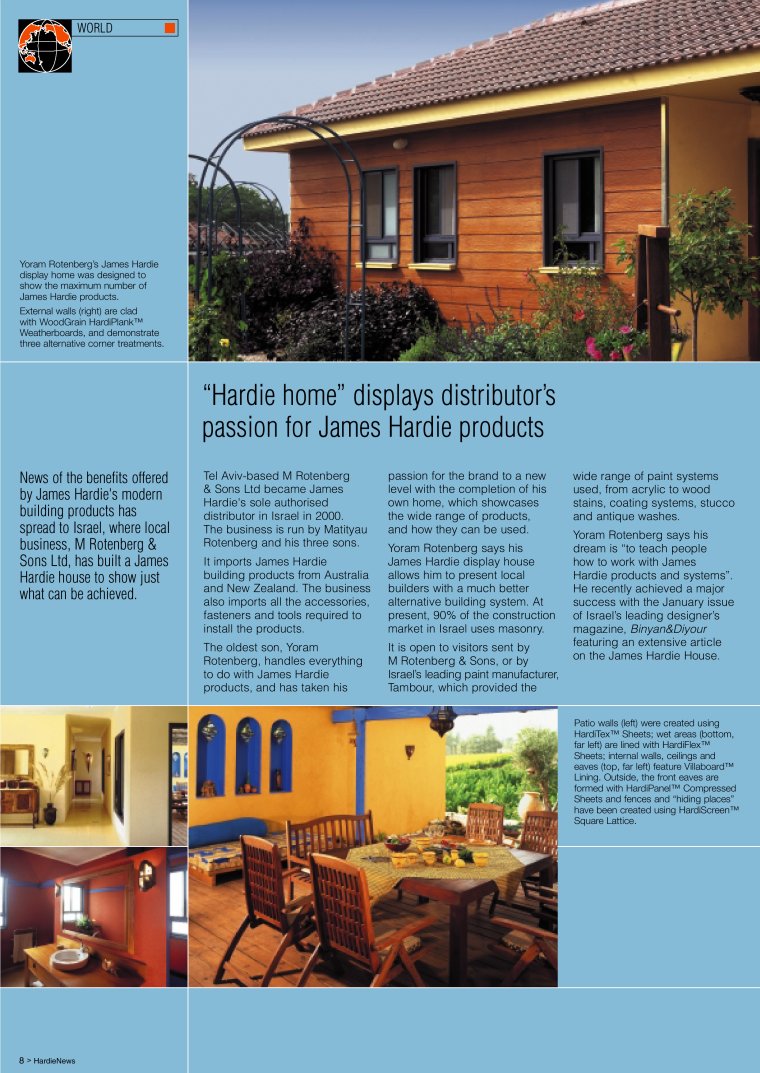

| WORLD

Yoram Rotenberg’s James Hardie display home was designed to show the maximum

number of James Hardie products. External walls (right) are clad with WoodGrain

HardiPlank™ Weatherboards, and demonstrate three alternative corner treatments.

News of the benefits offered by James Hardie’s modern building products has

spread to Israel, where local business, M Rotenberg & Sons Ltd, has built a

James Hardie house to show just what can be achieved.

“Hardie home” displays distributor’s passion for James Hardie products

Tel Aviv-based M Rotenberg & Sons Ltd became James Hardie’s sole authorised

distributor in Israel in 2000. The business is run by Matityau Rotenberg and

his three sons.

It imports James Hardie building products from Australia and New Zealand. The

business also imports all the accessories, fasteners and tools required to

install the products.

The oldest son, Yoram

Rotenberg, handles everything to do with James Hardie products, and has taken

his passion for the brand to a new level with the completion of his own home,

which showcases the wide range of products, and how they can be used.

Yoram Rotenberg says his James Hardie display house allows him to present local

builders with a much better alternative building system. At present, 90% of the

construction market in Israel uses masonry.

It is open to visitors sent by M Rotenberg & Sons, or by Israel’s leading paint

manufacturer, Tambour, which provided the wide range of paint systems used,

from acrylic to wood stains, coating systems, stucco and antique washes.

Yoram Rotenberg says his dream is “to teach people how to work with James

Hardie products and systems”. He recently achieved a major success with the

January issue of Israel’s leading designer’s magazine, Binyan&Diyour featuring

an extensive article on the James Hardie House.

Patio walls (left) were created using HardiTex™ Sheets; wet areas (bottom, far

left) are lined with HardiFlex™ Sheets; internal walls, ceilings and eaves

(top, far left) feature Villaboard™ Lining. Outside, the front eaves are formed

with HardiPanel™ Compressed Sheets and fences and “hiding places” have been

created using HardiScreen™ Square Lattice.

8 > HardieNews

|

| WORLD James Hardie announced in December that it has re-negotiated its long-term debt, retiring US$60 million of long-term debt. The balance of long-term debt is now US$165 million and has an average maturity of 6.5 years at an average interest rate of 7.1%. James Hardie retires US$60 million of long-term debt The retirement of the debt will result in a saving of US$1.065 million in interest costs for the balance of the current fiscal year and annual savings of US$4.26 million in interest costs for the remaining term of the debt. The savings will be offset in the current year by a make-whole payment of US$9.9 million arising from the earlier than planned retirement of the debt. The make-whole payment was charged to interest expense in the income statement in the third quarter of the current year, and will have an after-tax impact of US$5.95 million. The changes are part of the new capital management strategy The sale of the gypsum plants enabled James Hardie to pay a tax-free return of capital to shareholders of US20 cents a share in November 2002. “The company now has a strong cash position which offers the potential of further tax-free returns of capital or other forms of returns to shareholders,” said James Hardie’s Chief Executive Officer, Peter Macdonald. ASIA PACIFIC To reinforce its commitment to safety, James Hardie has released a new Environment Health & Safety policy for its operations in the Asia Pacific region. Policy confirms JH commitment to safety and the environment The policy outlines the company’s guidelines and beliefs for what is required to achieve a safe working environment. The new policy was signed off by James Hardie CEO, Peter Macdonald, during a visit to Australia in December. It states that Employee Health, Safety and the Protection of the Environment are critical to the way we operate and do business. Key points include: >All injuries, occupational illnesses and incidents are preventable. Our goal is zero injuries. >We strive to continuously improve our EH&S performance. The implementation of sound management systems, training, regular review and corrective action are priorities. >All employees, contractors and visitors must comply with our EH&S Standards and all relevant legislation. >We continue to seek ways to efficiently use materials and energy to reduce waste and emissions. >All employees have a responsibility to themselves and others to act in a way which contributes to a safer, healthier and improved environment at work, at home and in the community. >If injuries do occur, we provide a rehabilitation program that promotes a rapid recovery, consistent with medical advice. The policy concludes with the statement that “We will conduct our business with respect for people and the environment”. |

| Copies of the policy will be communicated to all employees, and displayed in workplaces throughout the region.

9 > HardieNews

|

| UNITED STATES

USA builders, homeowners and remodellers now have more ways to brighten their

homes’ exteriors and reduce maintenance.

ColorPlus™ Collection offers more

James Hardie has added three colours to its ColorPlus™ Collection of

pre-finished siding products. Redwood, a warm, classic red, Slate Blue, a

crisp, timeless blue and Colonial Grey, a classic neutral, were selected based

on their popularity among national paint manufacturers.

James Hardie’s ColorPlus™ Collection gives builders and remodellers siding that

does not have to be painted, thereby preventing costly delays that can occur

when weather prevents a project from being completed.

The collection includes 11 colours ranging from vibrant red to soft pastels.

There is also a finish that reproduces the look of natural cedar.

James Hardie supports its ColorPlus™ Collection with two warranties: up to a

50-year limited transferable product warranty against rotting, cracking and

delaminating, and up to a 15-year warranty on the paint finish.

All ColorPlus™ Collection finishes are offered on lap and shingle panel siding

as well as trim boards and fascia and soffit panels. There is also a full line

of matching accessories including nails, caulk, touch-up paint and metal

accessories.

Redwood Slate Blue Colonial Grey

WORLD

Creative Problem Solving workshops held in Australia and America in January

have shown James Hardie Research & Product Development employees how to use

innovation as an everyday problem-solving tool.

Innovation will help James Hardie perform in any market and meet the business

challenges of today and the future.

Solutions through innovation

More than 40% of James Hardie’s Research & Product Development employees

participated in Creative Problem Solving (CPS) workshops held in January.

The workshops were run at the company’s two R&PD centres, in Fontana

(California) and Rosehill (Sydney) by Mary Wallgren, James Hardie’s Director of

Innovation, and William Shephard, Vice President of Group Services for the New

York-based Creative Problem Solving Group, Inc, which developed the course.

Participants were taught the CPS process including both generating and

focussing tools. They also applied the CPS process and tools to solve one of

their own business problems during the course. These problems covered areas as

diverse as the testing efficiency of the durability rigs; effective

multi-tasking in the job; and minimising distractions in the workplace.

“During tough economic times such as these, companies often put innovation on

the back burner, thinking it’s only about new products and services,” explained

Mary Wallgren. “However, innovation has the capacity to cut costs and solve

problems throughout the organisation, and do it in a way that develops

important capabilities for the future.”

The CPS class will be repeated soon for those who were unable to attend the

first session. Other creativity and innovation classes designed to address

specific types of problems, and provide advanced processes and tools, are

planned for later in the year.

10 > HardieNews

|

| export

ASIA PACIFIC

FRC Pipes targets Vietnam building boom

James Hardie FRC Pipes has won its first major export order to supply the

Sanishute™ Disposal System in Vietnam.

Photographed at the Sanishute™ Disposal System seminar held in Hanoi in October

were (6th from left) Phan Ho Phuong, Managing Director of Binh Nguyen

Engineering; (5th from left) Oliver Mason from JH FRC Pipes and (4th from left)

Vy Thi Minh Tam, Technical Engineer, Binh Nguyen Engineering. Also in the photo

are Jim Truss (7th from left) of Odorout Systems Australia, which uses FRC

Pipes to create an exhaust vent system for high-rise buildings, and (on the far

right) Nguyen Dinh Ngai, BNE Sales Manager.

Vietnamese project developers seeking to improve the standard of their

high-rise apartment complexes have selected the Sanishute™ Disposal System

produced by FRC Pipes.

The Sanishute™ System uses lengths of fibre reinforced concrete pipes,

manufactured with rebated ends to allow for simple, effective jointing. The

result is a neat, purpose-engineered gravity system that can be used to dispose

of garbage, linen or mail in multilevel buildings.

The system was introduced to Vietnam by Oliver Mason, Market Development

Manager Asia for FRC Pipes, working with James Hardie’s North Vietnamese FRC

Pipes’ agent, Binh Nguyen Engineering. Last October, they hosted a technical

seminar in Hanoi, attended by over 100 local architects, builders, engineers

and developers.

After a successful trial installation in November, the major Vietnamese project

developer, Vinaconex, ordered the Sanishute™ System for its next five 17-storey

high-rise apartment buildings in Hanoi.

Orders have also been shipped for the Thang Long International and Huynh Thuc

Khang high-rise apartment projects.

“Before we introduced the Sanishute™ System, many Vietnamese architects

designed disposal systems using iron pipes and bricks. These have the

disadvantages of being rusty, smelly and noisy, so architects have welcomed the

new system,” explained Oliver Mason.

“Compared to the alternatives, the Sanishute™ System has many advantages: it is

a firerated system, has good acoustic qualities, it will not corrode or burn

and it is relatively low-maintenance. Added to that, it has been used

successfully in Australia for more that 25 years.”

Oliver Mason says that Vietnam is potentially a huge market for the Sanishute™

System: “There are over 400 high-rise buildings proposed for Hanoi in the next

few years, and indications of at least one project of 1,000 apartments by

2020,” he explained.

The building in the foreground was the first in Vietnam to have the Sanishute™

System installed. The system is now being installed in the next five buildings

in the background.

11 > HardieNews

|

| UNITED STATES Charity drives spread Christmas cheer The generosity of James Hardie employees made last Christmas more cheerful for some disadvantaged children. Employees at the USA offices in Mission Viejo used their fifth annual charity toy drive to make Christmas brighter and happier for children helped by the local Kids Matter Auxiliary. Organiser Cathy McCutcheon reported 81 gifts, as well as some cash, were donated this past year. “This allowed us to fulfil the specific wishes of 27 children, and provide additional gifts to support the Auxiliary’s Santa program,” she said. The Kids Matter Auxiliary runs a Santa Wish List Program to help children in Orange or LA County. The auxiliary provides gifts for children aged between infant and 12 for boys, and 18 for girls. All have been removed from their abusive homes by court order. Since they started supporting the toy drive in 1998, James Hardie employees have donated over 450 gifts, as well as quantities of board games and art supplies for the various “houses”. In a letter thanking the employees for their support, Pat Williams, the president of the Kids Matter Auxiliary said: “Many of our kids are not hopeful when they ask for a Santa gift. They have been disappointed so many times by so many people that they never really expect to receive anything. But receive they did. Every single child had several beautifully-wrapped presents just for them”. She went on to say: “Know that every single gift was so appreciated by every individual” and gave as an example a teenage girl who refused to take the store tags off her new jacket days after Christmas, because she had never had a new coat. |

| The children... “played with their toys, tried out new pajamas and generally |

| made lots of happy noise with new music blaring from everywhere. It is sheer happiness that you brought these many children with your caring. They learned the greater gift that people can be good. People care about them. It helps them understand that they are worth caring about”. PHILIPPINES JHPI Project Sales Manager, Gigi Lapira (centre) and Assistant Product Manager, Lei Punsalang (second from right) receive the Top Building Board Brand of the Year Award from Jonathan Navea, Lolita Escobar-Mirpuri and Celia Umali of the National Consumer Affairs Foundation James Hardie’s HardiFlex™ brand was named the Top Building Board Brand of the Year at the 19th Philippines Year-Ender Consumers Choice Awards presented on December 30, 2002. HardiFlex™ leadership status cemented by award The Year-Ender Consumers Choice Awards are conferred annually by the National Consumer Affairs Foundation and the Parangal ng Bayan Foundation to recognise products, services, manufacturers and companies that have served the well-being of the general public. Accepting the award for James Hardie, Project Sales Manager, Gigi Lapira, said the company was “excited and honoured”. “It’s a nice way to end a very busy and productive year,” she added. |

| HardiFlex™ won after open public nomination, which was further validated by random consumer surveys and research conducted by the National Consumer Affairs |

| Foundation’s Awards and Executive Committee. Those who attended the awards night heard a message from Philippines President, Gloria Macapagal Arroyo, who said: “Our national achievers... serve as vital |

| backbones of our country’s development. This event is a reminder that –given the proper opportunities –citizens can be potent forces in nation building”. 12 > HardieNews |

| PHILIPPINES

A clever promotional campaign has significantly increased awareness of

HardiFlex® sheets amongst Filipinos.

Buy a Board, Fly Abroad!

A nationwide raffle promotion that invited consumers to Buy a Board, Fly Abroad

has helped James Hardie Philippines increase the awareness – and use – of

HardiFlex® lite and HardiFlex® 4.5 sheets.

The promotion ran from October 2002 to January 2003 and was open to all

homeowners or contractors who bought

HardiFlex® lite and HardiFlex® 4.5 sheets. Every board they purchased entitled

them to one coupon. Grand prizes include trips to Los Angeles, Bangkok and Hong

Kong. Other prizes included Palm Pilots, Sony PlayStation II, Nokia cellular

phones, Philips Portable CDs and radios, Sony Discman and gift certificates.

“The HardiFlex® Buy a Board, Fly Abroad promotion helped us achieve our 3rd

quarter sales objective,” reported Assistant Product Manager, Lei Punsalang.

“It also generated added awareness and excitement in the trade.”

Photographed at the drawing of the major prizes were (L to R) James Hardie

Philippines’ Vice President Sales and Marketing, Rob Kidd; National Sales

Manager, Jett Bije; Assistant Product Manager, Lei Punsalang; Department of

Trade & Industry representative, Mena Alea; and James Hardie Philippines’

Marketing Manager, Junie Rondon. The competition poster (right) captured the

“fly abroad” prize.

ASIA PACIFIC

With the launch of the second stage of the SAP project, managers in Australia

and New Zealand are being introduced to a powerful reporting system that will

eventually allow them to analyse almost any aspect of their business’s

performance.

Business Warehouse delivers more detailed information, faster

The Australian and New Zealand building products and FRC Pipes businesses are

implementing the second stage of the SAP project, to help managers improve

their decision-making by giving them dynamic on-screen business analysis.

The new development, called Business Information Warehouse, has access to all

the business information collected in the first year of SAP’s operation, as

well as three year’s of sales history. Each night, sales data is extracted from

SAP and loaded onto a separate Business Warehouse server, for faster, more

efficient access and analysis.

SAP project manager, Darren Thompson, explained the benefits: “Business

Warehouse lets managers get any up-to-date information they want, anytime they

want it. It gives them a much clearer idea of what is happening in all areas of

their business, so they can clearly identify areas that require action and

resolve issues faster.”

Initially, Business Warehouse covers Sales information, allowing analysis

across all levels of James Hardie’s organisation, products and customers. Sales

and marketing teams are using Business Warehouse to measure sales performance

for the areas they are responsible for.

In the future, it will be expanded to cover Financial Management Reports,

Profitability Analysis, Order Fulfilment, and Supply Chain.

Noni Hannah, National Sales Administrator for Building Products Australia, says

the new program has made life much easier. “A report that used to take me at

least a whole day’s work now takes me seconds to refresh every quarter, and I

know the data is accurate because it’s coming directly from SAP,” she said.

“Every day I’m asked for sales reports comparing customers by product for

multiple years. This used to take two days, but with Business Warehouse, I can

prepare these in five minutes.”

13 > HardieNews

|

| AUSTRALIA

Employees from James Hardie’s Meeandah pipe plant are among the first people in

Queensland to be accredited under new competency-based standards for

Manufacturing.

Another milestone for FRC Pipes

Eight employees from the FRC Pipes plant at Meeandah (Queensland) have achieved

a Certificate II in Manufactured Mineral Products. This is the second level in

a new competency-based Manufactured Mineral Products – Process Manufacturing

training package.

The training is recognised within the Australian Qualification Framework and

involves on-the-job learning and assessment against National Competency

Standards. The Meeandah employees were assessed by fellow-workmates, Mark

Marshall and Max Revell, at the time the only two qualified Certificate IV

Trainer Assessors on site. Mark and Max were supported by Jenny Ruff, Human

Resources Manager at Building Products Rosehill (Sydney) and Michael McLeay, a

registered training provider.

Mark Marshall has now been promoted from Quality Assurance Operator to

Distribution Team Leader, and he will continue implementing the Warehouse &

Distribution training in his new area. Two new Manufacturing assessors – Adam

Brind and Tony Gray – are being trained to continue the good work started by

Max and Mark.

Niki Whaanga (Lathe Team Leader), Dave Lockett (Mazza Team Leader), Max Revell

(Quality Assurance Operator), Allan Saunders (Machining Process Team Leader),

Adam Brind (Raw Materials Operator), Danny Banfield (Electrician) and Michael

McLeay (Registered Training Provider). Missing from the photo are Mark Marshall

(Distribution Team Leader) and Nigel Buchanan (Lathe Team Leader)

Inset: The trainers (L to R) Mark Marshall, Distribution Team Leader; Michael

McLeay (Registered Training Provider); and Max Revell, Quality Assurance

Operator.

NEW ZEALAND

Linea® combines R&D, technology and performance to grow the market for

weatherboards

Cover story continued

Sales in each quarter since the launch have significantly exceeded targets with

full year sales likely to be more than double the estimate in the product’s

first year.

Market Segment Manager for Weatherboards, Craig Chetty, attributes the success

of Linea® to its inherent benefits: “It has a host of advantages over

traditional timber weatherboards, and none of the shortcomings,” he said.

“It’s easy to maintain and features a tongue and groove end profile that

creates an almost-invisible lateral butt-joint that eliminates the need for

back soakers, makes installation easier and minimises waste.

“Then there are design options, like choice of corners, trim profiles and door

and window facings. It’s a breeze to paint or stain and the stability of the

formulation means designers and homeowners can use dark colours without

worrying that they will cause the boards to warp.

“Finally, because the Linea® formulation resists pests of all kinds, and won’t

rot, warp or burn, it is particularly recommended for challenging climates,

including those exposed to coastal salt-spray.”

The quality of the Linea® offer is enhanced by three warranties: a 25-year

warranty on the weatherboards, a 15-year extended warranty on the paint; and a

60-minute fire rated system warranty.

14 > HardieNews

|

| AUSTRALIA Award winning features The clients wanted a spacious family home with clean, minimalist forms, subtle Asian influences and a commercial appearance for the exterior. The rectangular site was small – approximately 415 square metres with a frontage of just 11 metres. It was part of a subdivision in an inner-southeastern suburb of Adelaide (South Australia) and the local council required homes built in this urban re-development project to reflect the form, scale, design and character of the area. Using the James Hardie CMX™ Compact Masonry Walling System from James Hardie, Bill Adams from WJ Adams Building Designer fulfiled the requirements set by his clients and the local council, and overcame the limitations of the site, to achieve an award-winning house. The modern, minimalist home meets the clients’ brief for appearance and layout. A second storey over the centre of the home provides space, without increasing the visual bulk from the street. External private courtyards achieve the required setback from boundary. To complement the existing streetscape, a staggered garage facade was recessed behind the home’s primary portico facade. Bill Adams used the CMX™ Walling System for all the home’s exterior walls and attributes internal and external benefits to its features. Inside, the CMX™ System helped maximise floor areas, since each wall takes up less space than masonry. Because the CMX™ System achieved a fire-rated wall, the garage wall could lie on the boundary. The quality of the finish meant there were no obvious joints on the walls, just the clean flat lines that recall a commercial office block. Finally, the speed of installation for the CMX™ System helped with the construction timeframe. The quality of the design was recognised at the 2002 South Australian Building Designers Association Design Awards, where it received the following awards: New Homes under 250m2 category – Certificate of Merit; Energy Efficient Design category – Award of Excellence; “People’s Choice” category –Award of Excellence. HardieNews is published by James Hardie Industries NV (ARBN 097 829 895) incorporated in The Netherlands. The liability of its members is limited. Level 3, 22 Pitt Street, Sydney. GPO Box 3935, Sydney 2001. www.jameshardie.com Editor: Shane Grimes Tel: +61 2 8274 5225 Fax: +61 2 8274 5218 email: [email protected] ™ and ® denote a trademark owned by or licenced to James Hardie company or James Hardie Research Pty Ltd (ABN 31 066 114 092). This document contains forward looking statements. Forward looking statements are subject to risks and uncertainties and, as a result, readers should not place undue reliance on such statements. The inclusion of these forward statements should not be regarded as a representation that the objectives or plans described will be realised. |