EXHIBIT 99.1

| James Hardie hardie news® December 2003 / Volume 3 Issue 2 / www.jameshardie.com New generation product puts James Hardie’s strengths on display The new ExoTec™ Facade Panel is being promoted as a “next generation” product for the Australian commercial facades market The Australian commercial construction industry is the latest segment to benefit from James Hardie’s commitment to product innovation, following the launch of the new ExoTec™ Facade Panel. Matt Woodley, General Manager, Sales & Marketing, describes ExoTec Facade Panels as “the next generation in engineered fibre composite panels for commercial facades”. “The new technology involved in the manufacture of ExoTec Facade Panels means we can offer a ten year warranty, double that offered on the highly successful HardiPanel™ Compressed Panel that ExoTec supersedes,” he said. ExoTec Facade Panels are factory-sealed on all six sides, and incorporate new technology that makes the product 20% more impact-resistant. Other advances include improved stability for a wide range of surface finishes, improved moisture- resistance and, because it requires 10% fewer fixings than the older HardiPanel Compressed Panel, faster and more efficient installation. “HardiPanel was a revolutionary product when it was launched, but our significant research advances, and our desire to continually deliver innovative product solutions for our customers, led us to develop the ExoTec Facade Panel to replace it,” said Matt Woodley. ExoTec Facade Panels are available in two thicknesses, 9mm and 12mm; in standard lengths ranging from 1800 to 3000mm; and in three widths, 900, 1190 and 1200mm. |

| Complaining about the burden of governance is missing the point. Instead, it should be seen as a chance to restore credibility. WORLD It is over six months since the ASX launched its corporate governance guidelines and there are already troubling signs that form is winning the war over substance. Peter Macdonald, CEO James Hardie The guidelines were conceived with good intentions, requiring greater transparency and accountability from companies in the wake of corporate collapses that have cost investors billions. The federal government and the ASX have so far rightly refrained from over-reaching regulation, instead opting for a light-handed approach that upgraded the rights of shareholders while acknowledging that investment, by companies and their shareholders, involves risk. Like the regulatory reforms proposed in CLERP 9, the guidelines are in response to widespread anger with and distrust of public companies. They reflect a passionate and growing disaffection among many Australians towards corporate Australia. Half of Australia’s adult population owns shares. Both the government and the opposition acknowledge that the failure of corporates to set their houses in order will make more draconian regulation almost a political inevitability, even though it is not the best solution. The message is clear: corporate Australia must respond to the legitimate concerns of disaffected investors, restore its credibility and recapture the trust and confidence of shareholders, and the wider community. Business risks its credibility by becoming vocal about the burden of adopting the guidelines, complaining that too much management time is being consumed, that the process is degenerating into box-ticking and that all of this is compromising the creation of wealth for shareholders. Sitting opposite are a number of activist groups and governance advisory firms along with a flotilla of ‘experts’ that are already criticising companies that have not yet complied with the guidelines. Companies should view the guidelines as an opportunity to undertake a highly critical self-assessment to test whether their governance model has integrity and provides a sound moral framework for ethical decision-making. Complaints about the burden of compliance can be interpreted as business being unwilling to explain its actions or embrace change. Continued on page 11 James Hardie announced a 43% increase in 2nd quarter operating profit from continuing operations to US$32.8 million for the three months ended 30 September 2003. Among the 2nd quarter highlights, net sales increased 24%, gross profit was up 26% and EBIT1 increased 35% to US$47.9 million. 1. EBIT is defined as operating income. EBIT margin is defined as EBIT as a percentage of our net sales. We believe EBIT and EBIT margin to be relevant and useful information as these are the primary measures used by our management to measure the operating profit or loss of our business. EBIT is one of several metrics used by our management to measure the cash generated from our operations, excluding the operating cash requirement of our interest and income taxes. Additionally, EBIT is believed to be a primary measure and terminology used by our Australian investors. EBIT and EBIT margin should be considered in addition to, but not as a substitute for, other measures of financial performance reported in accordance with accounting principles generally accepted in the United States of America. EBIT and EBIT margin, as we have defined them, may not be comparable to similarly titled measures reported by other companies. The use of EBIT and EBIT margins in this document are equivalent to the US GAAP measures of operating income and operating income margin. 2. Operating profit from continuing operations is equivalent to the US GAAP measure of income from continuing operations. 3. Net operating profit including discontinued operations is equivalent to the US GAAP measure of net income. This is an extract of the full James Hardie FY04 2nd Quarter and Half-year results presentation. The full package of material, and an audio-cast of the results presentation, can be found on the Results page of the Investor Relations website, at www.jameshardie.com 1 > HardieNews James Hardie® |

| Half Year Results results >2nd Qtr Operating Profit Up 43% to US$32.8m >Half Year Operating Profit up 45% to US$65.7m The USA Fibre Cement business was again the standout performer lifting sales 24% and EBIT1 32% compared to the same period a year ago. In Asia Pacific, EBIT1 increased 16%. The 2nd quarter result lifted half year operating profit from continuing operations to US$65.7 million. EBIT1 from our USA Fibre Cement segment was up 36% for the half and Asia Pacific Fibre Cement was up 15% for the half. Basic earnings per share from continuing operations increased 54% from US 5.0 cents to US 7.2 cents for the 2nd quarter and 46% from US 9.9 cents to US 14.5 cents for the half year. The half year net operating profit including discontinued operations of US$67.5 million includes income of US$1.8 million primarily related to the sale of our New Zealand Building Systems business on 30 May 2003. The net operating profit including discontinued operations for the half year of the previous year includes a profit of US$55.1 million primarily related to the sale of our Gypsum business. Commentary James Hardie’s CEO, Peter Macdonald said: “The second quarter result mirrors the strong performance of the first quarter and prospects for the balance of the year remain encouraging. 2nd Quarter and Half Year at a Glance US$million Q2FY04 Q2FY02 %+\(-) HYFY04 HYFY03 %+\(-) Net Sales $251.6 $202.1 24 $493.1 $396.7 24 Gross Profit 92.4 73.6 26 181.7 142.1 28 EBIT1 47.9 35.6 35 96.2 70.7 36 Net Interest Expense (2.4) (2.5) (4) (4.7) (5.4) (13) Income Tax Expense (9.4) (9.9) (5) (22.5) (20.0) 13 Operating Profit 32.8 23.0 43 65.7 45.4 45 from continuing operations2 Net Operating Profit 32.8 24.6 33 67.5 100.5 (33) including discontinued operations3 Unless otherwise stated, results are for continuing operations only and comparisons are of the 2nd quarter of the current fiscal year versus the 2nd quarter of the prior fiscal year “The outlook for housing construction in North America is positive and it now appears likely that housing starts will finish the year at a new record high. “We are continuing to penetrate both the exterior and interior product markets of the USA without sacrificing margin, and this is resulting in strong top line growth,” Mr Macdonald said. USA Fibre Cement Continued Strong Growth and Higher Margins Net sales increased 24% to US$191.4 million in the 2nd quarter due to a 16% increase in sales volume to 390.5 million square feet and a 7% increase in the average selling price to US$490 per thousand square feet. Strong growth continued in both the exterior and interior product markets. Average selling prices were again up due to sales of higher-priced, differentiated products increasing as a proportion of total sales. Strong revenue growth and further progress on costs lifted EBIT 32% to US$53.7 million for the quarter and 36% to US$107.8 million for the half. The EBIT margin for the quarter increased to 28.1% and was 28.5% for the half. 2 > HardieNews James Hardie® |

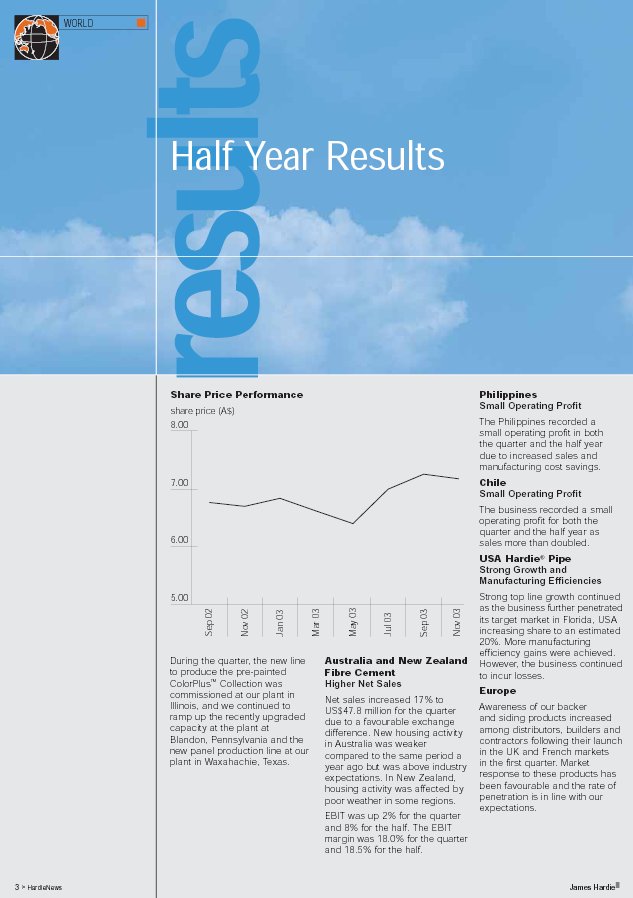

| WORLD Half Year Results results Share Price Performance share price (A$) 8.00 7.00 6.00 5.00 Sep 02 Nov 02 Jan 03 Mar 03 May 03 Jul 03 Sep 03 Nov 03 During the quarter, the new line to produce the pre-painted ColorPlus™ Collection was commissioned at our plant in Illinois, and we continued to ramp up the recently upgraded capacity at the plant at Blandon, Pennsylvania and the new panel production line at our plant in Waxahachie, Texas. Australia and New Zealand Fibre Cement Higher Net Sales Net sales increased 17% to US$47.8 million for the quarter due to a favourable exchange difference. New housing activity in Australia was weaker compared to the same period a year ago but was above industry expectations. In New Zealand, housing activity was affected by poor weather in some regions. EBIT was up 2% for the quarter and 8% for the half. The EBIT margin was 18.0% for the quarter and 18.5% for the half. Philippines Small Operating Profit The Philippines recorded a small operating profit in both the quarter and the half year due to increased sales and manufacturing cost savings. Chile Small Operating Profit The business recorded a small operating profit for both the quarter and the half year as sales more than doubled. USA Hardie® Pipe Strong Growth and Manufacturing Efficiencies Strong top line growth continued as the business further penetrated its target market in Florida, USA increasing share to an estimated 20%. More manufacturing efficiency gains were achieved. However, the business continued to incur losses. Europe Awareness of our backer and siding products increased among distributors, builders and contractors following their launch in the UK and French markets in the first quarter. Market response to these products has been favourable and the rate of penetration is in line with our expectations. 3 > HardieNews James Hardie® |

| “We are continuing to penetrate both the exterior and interior product markets of the USA without sacrificing margin, and this is resulting in strong top line growth.” Peter Macdonald, CEO James Hardie Artisan Roofing Plant testing and market trials continued during the quarter following the commissioning of our plant in June 2003. Sales of our new generation of fibre cement roofing products are expected to begin in the third quarter. Interim Dividend The Board has declared an interim dividend of US 2.5 cents a share. The dividend will be paid on 16 December 2003 to shareholders registered on 27 November 2003. Outlook In North America, the current level of housing activity is expected to continue, buoyed by low mortgage rates, strong house prices, an improving economy, low inventories of new homes for sale and large backlogs or orders for homes to be built. Indicators of future activity, including housing starts, permits and builder confidence, all remain at high levels. The National Association of Home Builders announced in September 2003 that “Housing production for 2003 should easily surpass last year’s very healthy 1.71 million and will likely approach the 1.8 million mark”. This follows housing start numbers exceeding a seasonally adjusted rate of 1.8 million for the past four months. Further strong top-line growth and profitability is expected as our USA Fibre Cement business continues to penetrate the northern and southern regions of the country and the exterior and interior product markets. In Australia and New Zealand, the commercial and renovations segments should remain strong but no improvement in new residential housing is expected. A better operating result is expected in the third quarter following the manufacturing performance of our Rosehill, NSW plant returning to more acceptable levels at the end of the second quarter and strong demand for higher-priced differentiated products such as Linea® Weatherboards in New Zealand. In the Philippines, building and construction activity is expected to increase as seasonal conditions become more favourable. Further share growth and manufacturing cost savings are expected. In Chile, recent signs of improved construction activity are expected to continue. Further market penetration and share growth is expected as awareness of our expanded product range continues to grow. The USA Hardie® Pipe business is continuing to increase production to meet growing demand, improve operating efficiency and reduce costs. In Europe, demand for our products is expected to grow as awareness among builders, contractors and distributors increases. Overall, the strong growth momentum evident in the first half is continuing into the third quarter and there is no sign of any near-term threat to highly satisfactory results overall for the full year. We are comfortable with the current range of analysts’ forecasts of operating profit from continuing operations for the 2004 fiscal year of between US$118 million and US$131 million. 4 > HardieNews James Hardie® |

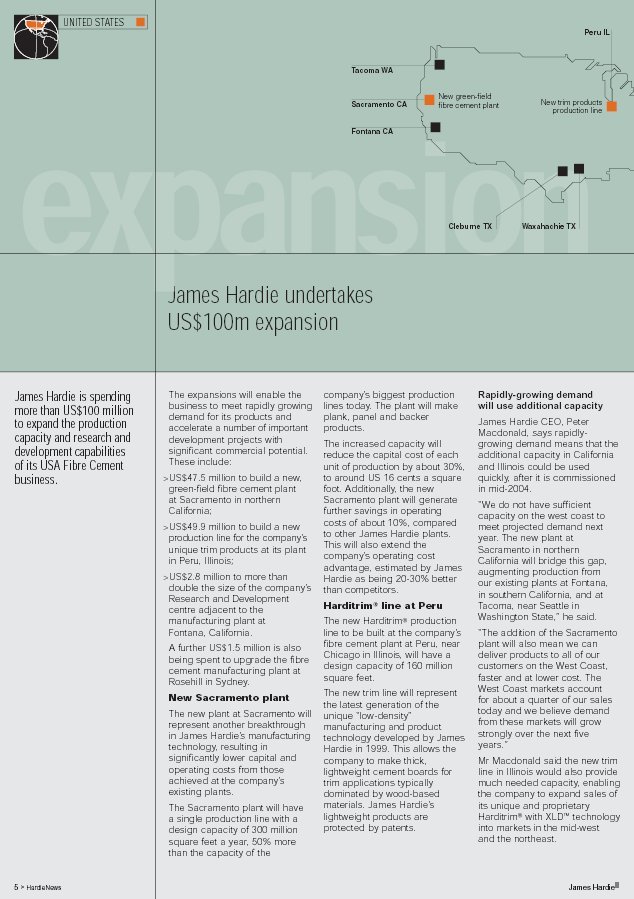

| UNITED STATES Peru IL Tacoma WA New green-field Sacramento CA New trim products fibre cement plant production line Fontana CA Cleburne TX Waxahachie TX James Hardie undertakes US$100m expansion James Hardie is spending more than US$100 million to expand the production capacity and research and development capabilities of its USA Fibre Cement business. The expansions will enable the business to meet rapidly growing demand for its products and accelerate a number of important development projects with significant commercial potential. These include: >US$47.5 million to build a new, green-field fibre cement plant at Sacramento in northern California; >US$49.9 million to build a new production line for the company’s unique trim products at its plant in Peru, Illinois; >US$2.8 million to more than double the size of the company’s Research and Development centre adjacent to the manufacturing plant at Fontana, California. A further US$1.5 million is also being spent to upgrade the fibre cement manufacturing plant at Rosehill in Sydney. New Sacramento plant The new plant at Sacramento will represent another breakthrough in James Hardie’s manufacturing technology, resulting in significantly lower capital and operating costs from those achieved at the company’s existing plants. The Sacramento plant will have a single production line with a design capacity of 300 million square feet a year, 50% more than the capacity of the company’s biggest production lines today. The plant will make plank, panel and backer products. The increased capacity will reduce the capital cost of each unit of production by about 30%, to around US 16 cents a square foot. Additionally, the new Sacramento plant will generate further savings in operating costs of about 10%, compared to other James Hardie plants. This will also extend the company’s operating cost advantage, estimated by James Hardie as being 20-30% better than competitors. Harditrim® line at Peru The new Harditrim® production line to be built at the company’s fibre cement plant at Peru, near Chicago in Illinois, will have a design capacity of 160 million square feet. The new trim line will represent the latest generation of the unique “low-density” manufacturing and product technology developed by James Hardie in 1999. This allows the company to make thick, lightweight cement boards for trim applications typically dominated by wood-based materials. James Hardie’s lightweight products are protected by patents. Rapidly-growing demand will use additional capacity James Hardie CEO, Peter Macdonald, says rapidly-growing demand means that the additional capacity in California and Illinois could be used quickly, after it is commissioned in mid-2004. “We do not have sufficient capacity on the west coast to meet projected demand next year. The new plant at Sacramento in northern California will bridge this gap, augmenting production from our existing plants at Fontana, in southern California, and at Tacoma, near Seattle in Washington State,” he said. “The addition of the Sacramento plant will also mean we can deliver products to all of our customers on the West Coast, faster and at lower cost. The West Coast markets account for about a quarter of our sales today and we believe demand from these markets will grow strongly over the next five years.” Mr Macdonald said the new trim line in Illinois would also provide much needed capacity, enabling the company to expand sales of its unique and proprietary Harditrim® with XLD™ technology into markets in the mid-west and the northeast. 5 > HardieNews James Hardie® |

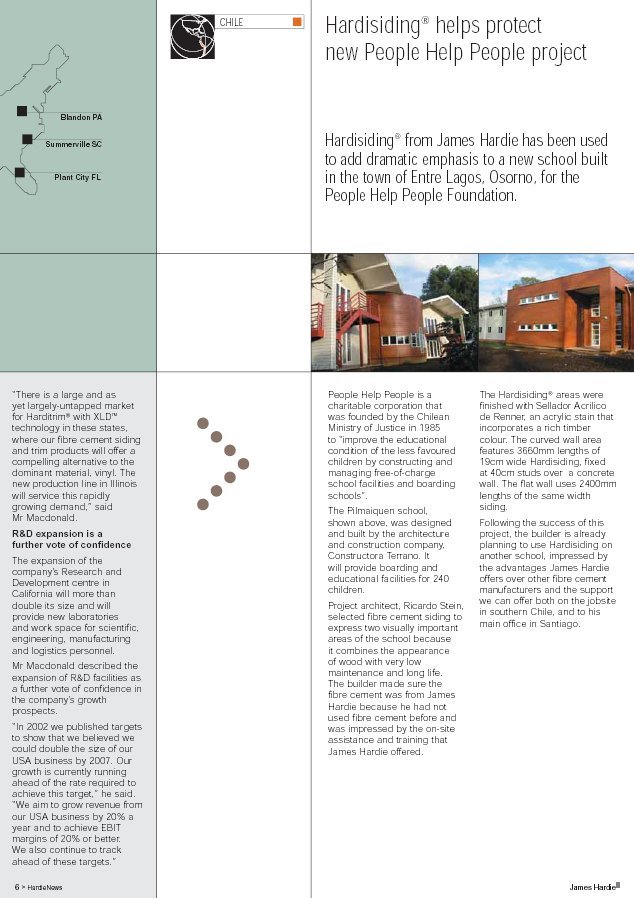

| Blandon PA Summerville SC Plant City FL CHILE “There is a large and as yet largely-untapped market for Harditrim® with XLD™ technology in these states, where our fibre cement siding and trim products will offer a compelling alternative to the dominant material, vinyl. The new production line in Illinois will service this rapidly growing demand,” said Mr Macdonald. R&D expansion is a further vote of confidence The expansion of the company’s Research and Development centre in California will more than double its size and will provide new laboratories and work space for scientific, engineering, manufacturing and logistics personnel. Mr Macdonald described the expansion of R&D facilities as a further vote of confidence in the company’s growth prospects. “In 2002 we published targets to show that we believed we could double the size of our USA business by 2007. Our growth is currently running ahead of the rate required to achieve this target,” he said. “We aim to grow revenue from our USA business by 20% a year and to achieve EBIT margins of 20% or better. We also continue to track ahead of these targets.” Hardisiding® helps protect new People Help People project Hardisiding® from James Hardie has been used to add dramatic emphasis to a new school built in the town of Entre Lagos, Osorno, for the People Help People Foundation. People Help People is a charitable corporation that was founded by the Chilean Ministry of Justice in 1985 to “improve the educational condition of the less favoured children by constructing and managing free-of-charge school facilities and boarding schools”. The Pilmaiquen school, shown above, was designed and built by the architecture and construction company, Constructora Terrano. It will provide boarding and educational facilities for 240 children. Project architect, Ricardo Stein, selected fibre cement siding to express two visually important areas of the school because it combines the appearance of wood with very low maintenance and long life. The builder made sure the fibre cement was from James Hardie because he had not used fibre cement before and was impressed by the on-site assistance and training that James Hardie offered. The Hardisiding® areas were finished with Sellador Acrilico de Renner, an acrylic stain that incorporates a rich timber colour. The curved wall area features 3660mm lengths of 19cm wide Hardisiding, fixed at 40cm studs over a concrete wall. The flat wall uses 2400mm lengths of the same width siding. Following the success of this project, the builder is already planning to use Hardisiding on another school, impressed by the advantages James Hardie offers over other fibre cement manufacturers and the support we can offer both on the jobsite in southern Chile, and to his main office in Santiago. 6 > HardieNews James Hardie® |

| UNITED STATES High quality materials contribute individual style Homes in the new Robinson Ranch estate in Santa Clarita, southern California, reflect both lifestyles and individual tastes. The estate’s developer, Pacific Bay Homes, wanted to create a neighbourhood of distinctive homes that would complement the magnificent setting with its beautiful rural landscape and neighbouring golf course. “We needed to keep to a production home schedule, but we wanted to maintain a custom-built look to the community,” explained Project Manager, Ralph Clemmer. “Individuality was important, as was the use of high quality materials and fittings, both inside and out.” These high quality materials include Hardishingle® siding, Harditrim® and Hardisoffit® panels, used here on a home designed by Michael Evans of Robert Hidey Architects. The house features a Dutch Colonial design and incorporates many authentic elements, from its shingle siding to a full-length front porch, wooden columns, shuttered dormer windows with crown moldings and a steep pitched roof. The style may be traditional, but the home makes the most of modern technology, in the form of Hardishingle siding. “The house has all the character and charm of a cedar shingle exterior, with the added advantage of low-maintenance and durability,” said Ralph Clemmer. “These qualities are important to many homeowners today who want a relaxed lifestyle and who have no wish to spend their free time working on the house. “Hardishingle siding also makes an interesting design alternative to stucco exteriors,” he added. AUSTRALIA Shareholders well-served by award-winning Investor Relations team The award-winning Corporate Affairs team (L to R): Steve Ashe, Vice President, Investor Relations; Julie Sheather, Vice President, Public Affairs; Greg Baxter, Executive Vice President; Shane Grimes, Corporate Communication Manager; and Samantha Leet, Executive Assistant James Hardie’s commitment to the highest standards of shareholder communication has been recognised by a record seven awards at the 2003 IR Magazine Australia Awards announced in Sydney on September 30.The awards were: >Grand Prix for Best Overall Investor Relations by an ASX-Top 100 Company (for the second year in a row) >Best Communication of Shareholder Value >Best On-going Management of Continuous Disclosure >Best Investment Community Meetings >Best Corporate Literature >Best Use of the Internet for Investor Relations, and >Best Investor Relations Officer - -awarded to Executive Vice President, Greg Baxter, for the third year in a row. James Hardie was also Highly-Commended in the category of Best Communication to the Finance Media. This is the fourth year that IR Magazine has surveyed the Australian investment community for its annual IR Magazine Australia Awards; and it is the third consecutive year that the research has been undertaken by independent research firm the Financial Research Company of Sydney. The Financial Research Company was responsible for the general part of the survey and for all of the Awards, except for those for Best Investor Relations to the Retail Market and Best Annual Report to the Retail Shareholder, which were polled by WILink. The subsequent Research Report and the associated IR Magazine Awards are part of a continuing series of events and research studies organised by IR Magazine in the UK, the USA, the Eurozone, Canada, Ireland, Latin America, Asia, South Africa, Central & Eastern Europe, and the Nordic Region. In Australia in 2003, 272 people responded to the general issues and attitudes part of the survey. They consisted of 128 investors and analysts on the sell or broker side, 133 on the buy or fund manager side and 11 financial journalists who answered only four questions in the general section and voted for only one award, for Best Investor Relations Communications to the Financial Media. Of the 261 investors and analysts, 200 respondents (90 were on the sell side, and 110 on the buy side) nominated award winners. Companies or individuals nominated in first place received three points or votes; those in second place received two points or votes; and those in third place, one point or vote. 7 > HardieNews James Hardie® |

| AUSTRALIA 2003 HIA Home & Building Exhibition builds on last year’s success James Hardie Building Products Australia has followed up on its success at last year’s HIA Home & Building Exhibition with a bigger and better presence at the 2003 exhibition, held in Brisbane in May. The exhibition ran over four days, one for trade and three for consumers. James Hardie’s 81 square-metre stand displayed the four PrimeLine™ Weatherboard profiles, the new Linea Weatherboards, HardiGlaze™ Tile Sheets, HardiGroove™ Lining, EziGrid™ Tilebacker, Villaboard™ Lining, the CMX™ System and Architectural Columns and Accessories. A member of the Building Designers Association of Queensland was also on hand to discuss design details with consumers who brought their house plans with them. Over 60,000 consumers visited the stand over the three days -double the number who attended last year’s two-day show — while 3000 people attended the trade day. The stand generated 40 consumer leads and 34 trade leads, all of which were subsequently followed-up by the Queensland sales team. Both consumer and trade visitors were impressed with the Linea® Weatherboards, with five builders wanting immediate delivery for display homes. Consumers were particularly taken with the weatherboard’s strong shadow line, dark paint colour and the stainless steel corner angles. To coincide with the show, James Hardie also held two CMX System workshops, as part of the seminar series organised by the local Courier Mail newspaper. These attracted 100 consumers. 8 > HardieNews James Hardie® |

| PHILIPPINES HardiePlank® Siding inspires Philippines’ architects to take the James Hardie design challenge James Hardie Philippines Inc recently hosted formal ceremonies at the Coconut Palace in Manila to recognise the winners of its first Innovations design competition. Innovations (L to R): the winning design by student Jeariel Tipay; Ongoing Residential Projects category winner, the Boracay beach house designed by architect Gerardo Roy Baniqued; and the Ongoing Commercial Project winner, designed by architect Jason So Grand prize student winner, Jeariel Tipay of the University of Sto Tomas College of Architecture (far right) receives his award from James Hardie Philippines’ Rob Kidd, Vice President Sales & Marketing and Gigi Lapira, Project Sales Manager The company announced the Innovations design competition in 2002, to coincide with the launch of HardiPlank® Siding. Inspired by the availability of this new versatile external wall cladding material that “combines the strength of concrete and homey look of wood”, architecture students and professionals from around the country enthusiastically accepted the challenge to explore the product’s aesthetic and functional potential. Jeariel Tipay of the University of Sto Tomas (UST) College of Architecture beat a field of some 30 entries to carry off the grand prize of PhP 20,000 in cash and a specially-designed Innovations trophy in the student division. In a clean-sweep for the University, Tipay’s schoolmates Aric Nathaniel Co and Amado Pascua Jr were named 1st and 2nd runners-up. In the professional division, judges selected the Boracay beach house designed by architect Gerardo Roy Baniqued for the Ongoing Residential Projects category and architect Jason So’s Ongoing Commercial Project in Lipa City, Batangas. The Residential and Commercial project categories were won by architects Francis Sta Romana and Jacinto Viado, respectively. The professional winners each took home PhP 50,000 in cash, Innovation trophies and trips to the USA. Innovation entries were judged by a panel consisting of professional and academic architects. WORLD John D Barr John Barr joins James Hardie Board John D Barr has joined the company’s Board as an independent, non-executive director. Mr Barr, a US citizen, has more than 30 years’ management experience in the North American industrial sector, including 25 years at The Valvoline Company, eight as President and Chief Executive Officer, in which time the company’s revenues doubled. Between 1995 and 1999 he was President and Chief Operating Officer and a member of the Board of Directors of the Quaker State Corporation, a leading automotive aftermarket products and consumer car care company, now part of Royal Dutch Shell. Since 1999, Mr Barr has been President and Chief Executive Officer of Automotive Performance Industries, a private US company that provides a variety of logistics services to major automotive manufacturers. Since December 2002, Mr Barr has served as a director of United Auto Group, the second largest publicly-held automotive retailer in the USA, and in August he was appointed to the Board of Directors of Clean Harbors Inc, the leading provider of hazardous waste and environmental management services throughout North America. James Hardie’s Chairman, Mr Alan McGregor, said Mr Barr will bring wide-ranging corporate and operating experience to the Board and has outstanding credentials as a builder of businesses. “John has real-world operating experience which will allow him to engage with senior management on critical strategies. He will challenge our thinking, bring fresh perspectives and a practical, no-nonsense orientation to the key issu es facing the company. His career in management roles and as a director shows that he is committed to helping build business that can sustain good performance over the long-term,” Mr McGregor said. “The appointment of Mr Barr, along with the recent election of Mr Peter Cameron and Mr Donald McGauchie, has broadened the Board’s professional and commercial expertise and geographic experience, all of which is vital to James Hardie’s continuing international development.” 9 > HardieNews James Hardie® |

| AUSTRALIA New swale pit caters for water sensitive urban design The FRC™ swale pit James Hardie FRC™ Pipes is well-placed to satisfy local authorities’ increasing demands to preserve the environment, with a range of slotted pits that make it easier to collect and manage roof water and ground water. The latest addition to the range is the FRC™ swale pit, which was developed in collaboration with several leading design consultants to address the management of roof water run-off, using water-sensitive urban design principles. These principles now emphasise minimum impact, not minimum maintenance. Initially, the slots in the lower body of the pit allow low flows of water run-off to be absorbed into permeable surrounds. When rainfall is so heavy that it can’t all be absorbed, excess water is diverted into a small outflow pipe, then into the surface drainage system. The James Hardie swale pit is provided with a galvanised grated lid and attached chain, which secures the lid to the pit. This keeps litter and other materials out of the pit, but still allows the lid to be lifted for any necessary cleaning. The characteristics of fibre reinforced concrete pipe bring many benefits to the swale pit, including lightweight composition, high strength, and durability. The absence of steel reinforcement in FRC™ circular pits allows easy drilling and cutting on site, and improves resistance to corrosion. AUSTRALIA Dr Reid (left) presents the James Hardie Australia Scholarship to honours year student, Peter Martin Dr Reid (right) unveils a plaque re-dedicating the James Hardie Dining Room in the University’s Centre for Professional Development, accompanied by Mr Laurie Willett, Chancellor, Charles Sturt University Former James Hardie chairman, Dr John Reid, recently attended two events at the Charles Sturt University in Bathurst, ensuring the company continues its close relationship with the area. John Reid maintains James Hardie’s links with Charles Sturt University Dr Reid presented the annual James Hardie Scholarship and attended a re-dedication of the James Hardie Dining Room in the University’s Centre for Professional Development. The James Hardie Scholarship is awarded to a student in any discipline in any year of study. Applicants are selected on the basis of academic merit, leadership, achievement and goals and motivation. This year’s scholarship was won by Peter Martin, an honours year student in the Bachelor of Human Movement (Honours) degree. In addition to contributing funds for the annual scholarship, James Hardie also contributed to the construction of the Centre for Professional Development, a 32-bed Convention Centre on the Bathurst campus, which was opened in 1994. This is an integral part of the University’s professional development program and a profit centre for the University. To acknowledge the company’s total contribution to the University, the Centre for Professional Development dining room was named the James Hardie Dining Room. Last year, the dining room was remodelled to increase its capacity and flexibility. The University took advantage of the annual Scholarship Presentation Ceremony to re-dedicate the room in the name of James Hardie, and record its thanks to John Reid, who together with Jim Kelso, former Director of Public Relations at James Hardie, “were instrumental in establishing and fostering the very close relationships between Mitchell College, Charles Sturt University and James Hardie”. 10 > HardieNews James Hardie® |

| PHILIPPINES Fire Prevention Month provided James Hardie Philippines with the perfect opportunity to explain to homeowners how the right building materials can protect their homes from fires. Fire Prevention Month helps spread the HardiFlex® word James Hardie Philippines took advantage of the country’s annual Fire Prevention Month in March to run its own Fire Prevention Consciousness Campaign on local television. Using the message Family Security is the #1 priority of any homeowner! the commercial focussed on one specific product attribute — the fire-resistance of HardiFlex® — to give homeowners an urgent and compelling reason to buy HardiFlex. The commercial observed that all homeowners are bound by the common fear of losing the roof over their heads and that this fear rises in proportion to the temperature, as in summer when temperatures reach the upper 30s and fire prevention tips begin to be flashed on TV. Instead of taking this seasonal approach, the commercial said that James Hardie seeks to do its share in reducing the risk of fires all year round, with fibre cement products that are “not only water-resistant and termite-proof, but are, especially, fire-resistant”. It concluded: “A safe home is a fire-resistant home. Ensure your family’s safety by using fire-resistant materials for the roof over your heads”. CANADA Quality finish reflects time spent in research Inspired by an advertisement for James Hardie siding in a USA design magazine, Canadian couple Bill and Sheila Campbell began a two-year program of internet and site research that eventually transformed their home in Edmonton, Alberta, Canada. The home has been transformed by Hardiplank® lap siding, and Hardishingle® siding. In October, Sheila Campbell wrote to James Hardie in the USA to tell us about the response to her re-clad home: “It has made our home so beautiful and the curb appeal is stunning,” she wrote. “We constantly have people stop in front of our place, and several times we have caught people taking pictures. “We are so happy we spent the money and used James Hardie siding products to complete the outside of our home. We certainly would not hesitate to use this product again, and continue to pass people onto your beautiful products.” In a subsequent conversation, Sheila Campbell praised the siding’s ability to withstand the local climate: “In our country, the weather is so cold,” she said. “The house faces South West, then there is the snow in winter. Wood really takes a beating here, but our siding hasn’t deteriorated at all.” The Campbells saw James Hardie siding products installed on homes in Oregon, in Vancouver and in the United States. They then found a local distributor and installer who could supply the siding, pre-painted in the Valpro paint colour, Pinedale, and shipped to the house ready for installation. According to Sheila, the project was well-worth the time and effort they put into researching it: “Lots of people around here are re-cladding with a vinyl California Stucco finish, but we wanted something more,” she said. “If you drive around you can instantly see the difference in quality between vinyl and fibre cement!” The Campbell’s remodelled home before (left) and after. 11 > HardieNews James Hardie® |

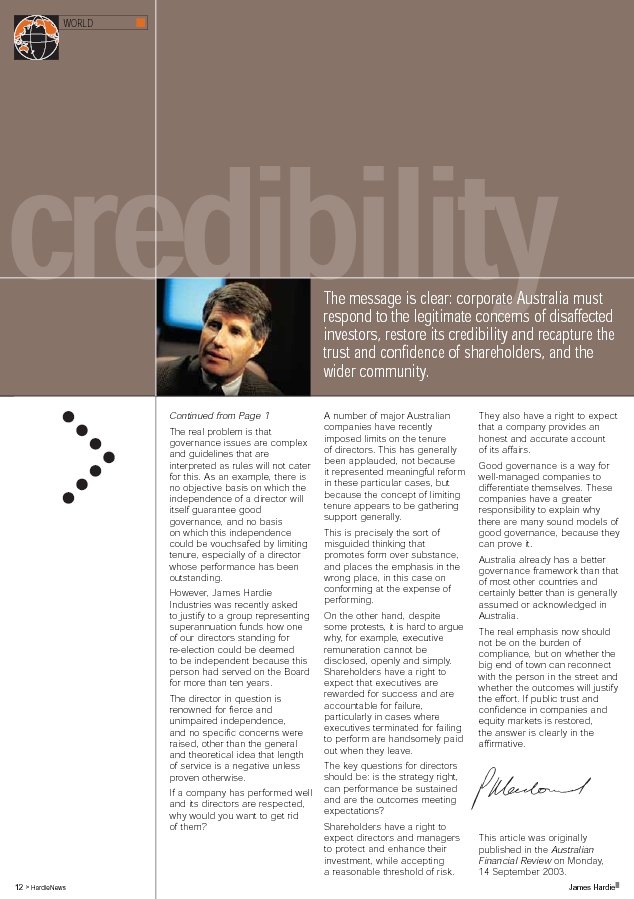

| WORLD credibility The message is clear: corporate Australia must respond to the legitimate concerns of disaffected investors, restore its credibility and recapture the trust and confidence of shareholders, and the wider community. Continued from Page 1 The real problem is that governance issues are complex and guidelines that are interpreted as rules will not cater for this. As an example, there is no objective basis on which the independence of a director will itself guarantee good governance, and no basis on which this independence could be vouchsafed by limiting tenure, especially of a director whose performance has been outstanding. However, James Hardie Industries was recently asked to justify to a group representing superannuation funds how one of our directors standing for re-election could be deemed to be independent because this person had served on the Board for more than ten years. The director in question is renowned for fierce and unimpaired independence, and no specific concerns were raised, other than the general and theoretical idea that length of service is a negative unless proven otherwise. If a company has performed well and its directors are respected, why would you want to get rid of them? A number of major Australian companies have recently imposed limits on the tenure of directors. This has generally been applauded, not because it represented meaningful reform in these particular cases, but because the concept of limiting tenure appears to be gathering support generally. This is precisely the sort of misguided thinking that promotes form over substance, and places the emphasis in the wrong place, in this case on conforming at the expense of performing. On the other hand, despite some protests, it is hard to argue why, for example, executive remuneration cannot be disclosed, openly and simply. Shareholders have a right to expect that executives are rewarded for success and are accountable for failure, particularly in cases where executives terminated for failing to perform are handsomely paid out when they leave. The key questions for directors should be: is the strategy right, can performance be sustained and are the outcomes meeting expectations? Shareholders have a right to expect directors and managers to protect and enhance their investment, while accepting a reasonable threshold of risk. They also have a right to expect that a company provides an honest and accurate account of its affairs. Good governance is a way for well-managed companies to differentiate themselves. These companies have a greater responsibility to explain why there are many sound models of good governance, because they can prove it. Australia already has a better governance framework than that of most other countries and certainly better than is generally assumed or acknowledged in Australia. The real emphasis now should not be on the burden of compliance, but on whether the big end of town can reconnect with the person in the street and whether the outcomes will justify the effort. If public trust and confidence in companies and equity markets is restored, the answer is clearly in the affirmative. This article was originally published in the Australian Financial Review on Monday, 14 September 2003. 12 > HardieNews James Hardie® |

| AUSTRALIA A new promotional campaign for the CMX™ System is encouraging builders and homeowners in Queensland, New South Wales, Victoria and South Australia to make a smarter choice of building materials Smarter than bricks James Hardie is targeting home builders and owners with a new campaign that highlights the benefits its CMX™ System offers over bricks. The Smarter than bricks campaign is well-timed, with brick manufacturers expected to fall short of consumer demand for bricks by a staggering 60 million bricks per year in Sydney alone. Because it is a lightweight building system that uses quality textures and paints provided by Dulux, Rockcote and Taubmans to provide the solid look and feel of a brick home, the CMX System is being promoted as a solution to the possible delays caused by the shortfall in bricks. Product Manager for James Hardie Building Products, Ashley Whitter, described the CMX System as the modern alternative to brick: “It goes up faster, so builders and renovators can reach ‘lock-up stage’ quicker; we offer a 10-year warranty; and - - most importantly - it is available now. “As land in cities becomes scarcer and building on difficult or sloping blocks becomes more common, renovators, builders and designers will welcome the design flexibility and speed that the CMX System can offer,” said Ashley. “Our aim is to make sure they are well-educated about all these advantages so they can make an informed choice.” The new campaign includes full and half-page advertisements in newspapers and building trade and consumer magazines; new technical and product literature; sales presentation materials including cut-away models that show the system’s components; and new product displays in Building Information Centres in all the states where the CMX System is available. 13 > HardieNews James Hardie® |

| WORLD 2003 Annual Meetings Over 150 James Hardie CUFS holders and visitors attended the Annual Information Meeting held in Sydney on August 13 to shareholders review the items of business and other matters to be considered and voted on at the Annual General Meeting held in The Netherlands on August 15. James Hardie Chairman, Alan McGregor, opened the meeting by explaining that it was intended to provide the company with an opportunity to report on its operations, and for CUFS holders to ask questions of the Board in relation to the business or any of the proposed resolutions. Mr McGregor used his annual address to review the company’s strong performance for the 2003 financial year; discuss the work being undertaken to increase production capacity in North America; and restate the company’s competitive advantages, market share and growth potential. In response to the considerable interest generated by his comments in the 2003 Annual Report, the Chairman also included a discussion about corporate governance in general, and at James Hardie, in particular, advising shareholders that the company has “sound and well-proven corporate governance practices”. “Shareholders will be reassured to know that our long-standing governance arrangements required only modest changes to documentation to accommodate the recent reforms and best practice recommendations developed in Australia and the United States,” he said. The company’s formal Annual General Meeting was held in Amsterdam two days later, on August 15. All the resolutions before the meeting were carried, with the majority of CUFS and share holders voting to: >Receive and adopt the Annual Accounts of the company for the year ended 31 March 2003 >Re-elect Ms Meredith Hellicar and Mr Michael Gillfillan to the company’s Supervisory and Joint Boards >Elect Mr Peter Cameron and Mr Donald McGauchie to the company’s Supervisory and Joint Boards >Approve Messrs Cameron and McGauchie as participants in the company’s Supervisory Board Share Plan >Elect Mr Folkert Zwinkels as a member of the company’s Managing Board >Renew the company’s authority to acquire its own shares >Increase the nominal value and convert the share premium >Approve a reduction of capital >Provide authority to amend the Articles of Association. Details of the number of votes cast for or against these resolutions (and abstentions) can be found on the Investor Relations website at www.jameshardie.com (select Annual Meetings, then Voting on 2003 AGM Resolutions). The Annual Meetings also provides access to a webcast of the Information Meeting, details of meeting participants and the Notice of Meeting. WORLD If you have access to a computer terminal, you have access to the latest investor relations information from James Hardie Industries. Investor Relations at www.jameshardie.com Clearly-labelled areas on the website provide fast access to: >current share price information >news >results >annual meetings, and >presentations The site also contains a comprehensive Corporate Governance area where you can review the company’s Corporate Governance practices, and see how these relate to the guidelines issued by the Australian Stock Exchange. A Shareholder Services area provides answers to Frequently Asked Questions, tax information and a glossary of terms used in connection with James Hardie, as well as access to the on-line version of this newsletter. To make it as easy as possible to keep up to date, the website also contains two forms where you can register to receive >an email reminder that a specific event such as quarterly results will occur within seven days, or >an email alert that new information you are interested in (such as results, management presentations, or news releases) has been posted to the site. 14 > HardieNews James Hardie® |

| NEW ZEALAND New TV Showhomes website links consumers, builders and architects One of the latest Linea® Weatherboard-clad homes to feature in the TV Showhomes program and website is this Waiheke Beach House, designed by Waiheke Island architect, Ron Stevenson A desire to broaden relationships with consumers online has led to the launch of a new website and interactive communications program for the popular TV Showhomes commercials www.tvshowhomes.co.nz The TV Showhomes concept has been very successful for James Hardie in New Zealand, profiling homes which have been built using Linea® Weatherboards and other James Hardie products. It has now been supplemented by a new magazine-style website that provides more in-depth information about the feature homes, including details about the products used, profiles on the architects and designers, and articles to help home builders and renovators achieve similar results. Brad Webster, Communications Manager, James Hardie TV Showhomes, explained the development of the new site: “Our TV Showhomes advertising had been successful, but we knew there was an opportunity to take our relationship with consumers a lot further using the web and email,” he said. In response, advertising agency, Lowe Worldwide, and specialist e-Marketing agency, Tango Communications have developed an interactive site that helps consumers through the whole building process -from the time they first start collecting ideas, to finding an architect or builder, through to painting the finished home. The new website features an innovative online scrapbook where consumers can collect ideas and information in one place. When they’re ready to brief an architect or designer, they can email their scrapbook as a PDF file. The scrapbook functionality was developed by a specialist company, Intergen, using Microsoft ASP.NET. It also features an email, fax and sms messaging component and an Architect and Builder Directory that creates a link between consumers and the trade. Consumers can search for architects or builders in their area, who specialise in new home or renovation projects. When a consumer requests contact from a participating builder, a text message is automatically sent to the builder, and a copy email goes to a James Hardie representative, who checks the builder has contacted the consumer, and provides any follow-up that’s required. An email marketing component allows James Hardie to email its TV Showhomes consumer database as new homes go to air, profiling the home and reminding the viewers that detailed related stories are on the website. HardieNews is published by James Hardie Industries NV (ARBN 097 829 895) incorporated in The Netherlands. The liability of its members is limited. Level 3, 22 Pitt Street, Sydney. GPO Box 3935, Sydney 2001. www.jameshardie.com Editor: Shane Grimes Tel: +61 2 8274 5225 Fax: +61 2 8274 5218 email: [email protected] ™ and ® denote a trademark owned by or licenced to James Hardie company or James Hardie Research Pty Ltd (ABN 31 066 114 092). This document contains forward looking statements. Forward looking statements are subject to risks and uncertainties and, as a result, readers should not place undue reliance on such statements. The inclusion of these forward statements should not be regarded as a representation that the objectives or plans described will be realised. 1 Copyright December 2003 James Hardie Australia Pty Ltd ABN 12 084 635 558 > HardieNews |