Exhibit 99.5 • Xxx • Xxx Zero Harm Ryan Kilcullen

AGENDA • History of safety at James Hardie • Zero Harm journey • Zero Harm approach & progress • Next steps PAGE 2

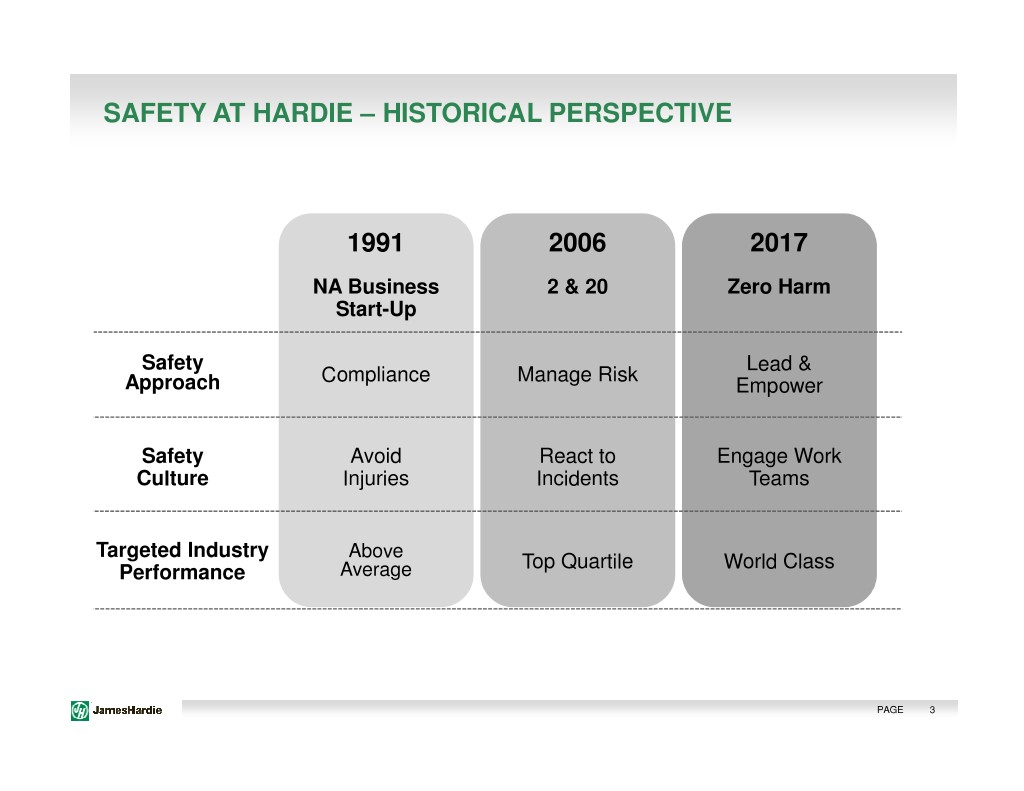

SAFETY AT HARDIE – HISTORICAL PERSPECTIVE 1991 2006 2017 NA Business 2 & 20 Zero Harm Start-Up Safety Lead & Compliance Manage Risk Approach Empower Safety Avoid React to Engage Work Culture Injuries Incidents Teams Targeted Industry Above Top Quartile World Class Performance Average PAGE 3

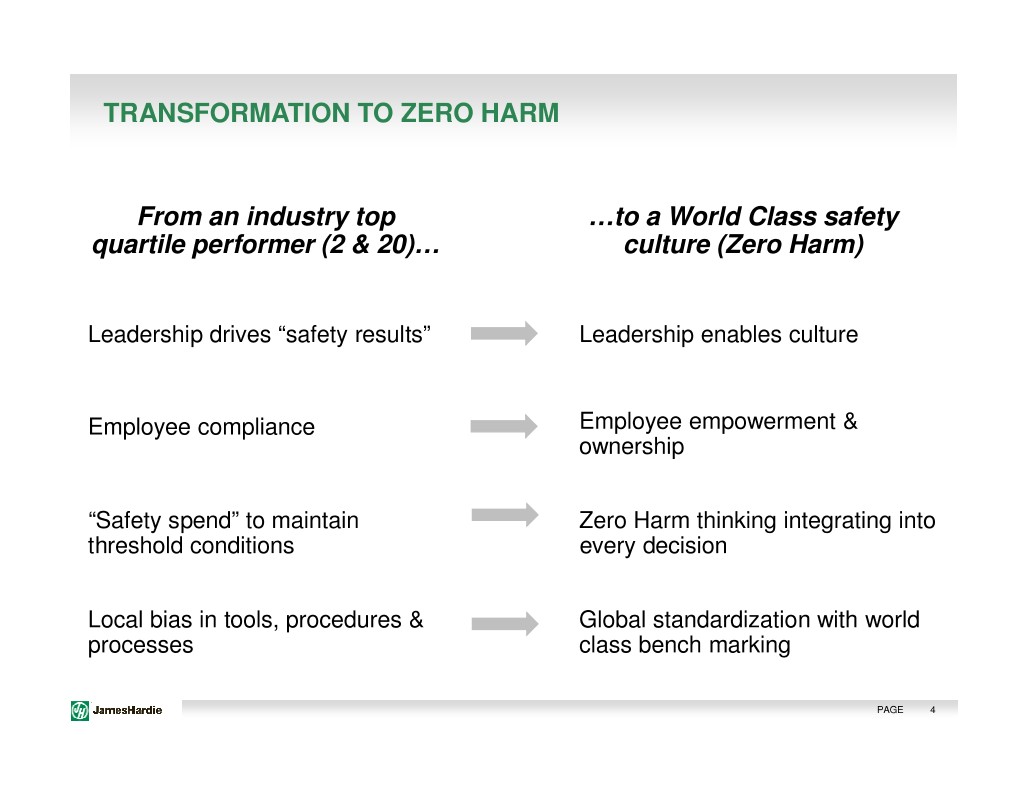

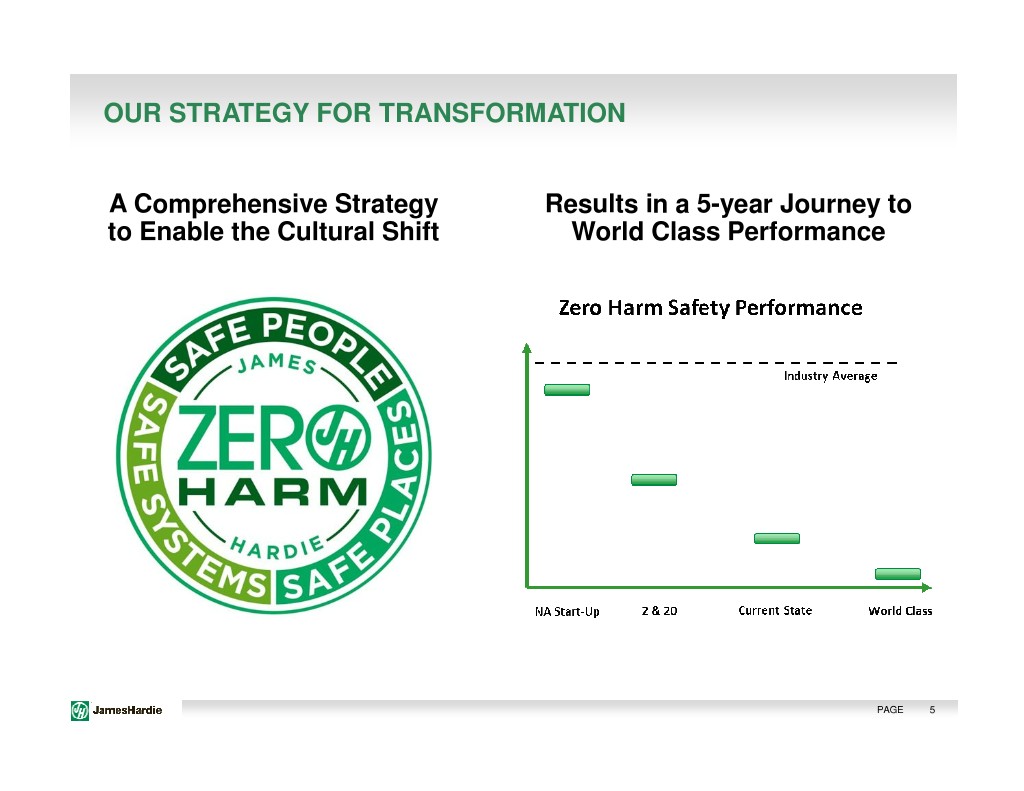

TRANSFORMATION TO ZERO HARM From an industry top …to a World Class safety quartile performer (2 & 20)… culture (Zero Harm) Leadership drives “safety results” Leadership enables culture Employee compliance Employee empowerment & ownership “Safety spend” to maintain Zero Harm thinking integrating into threshold conditions every decision Local bias in tools, procedures & Global standardization with world processes class bench marking PAGE 4

OUR STRATEGY FOR TRANSFORMATION A Comprehensive Strategy Results in a 5-year Journey to to Enable the Cultural Shift World Class Performance PAGE 5

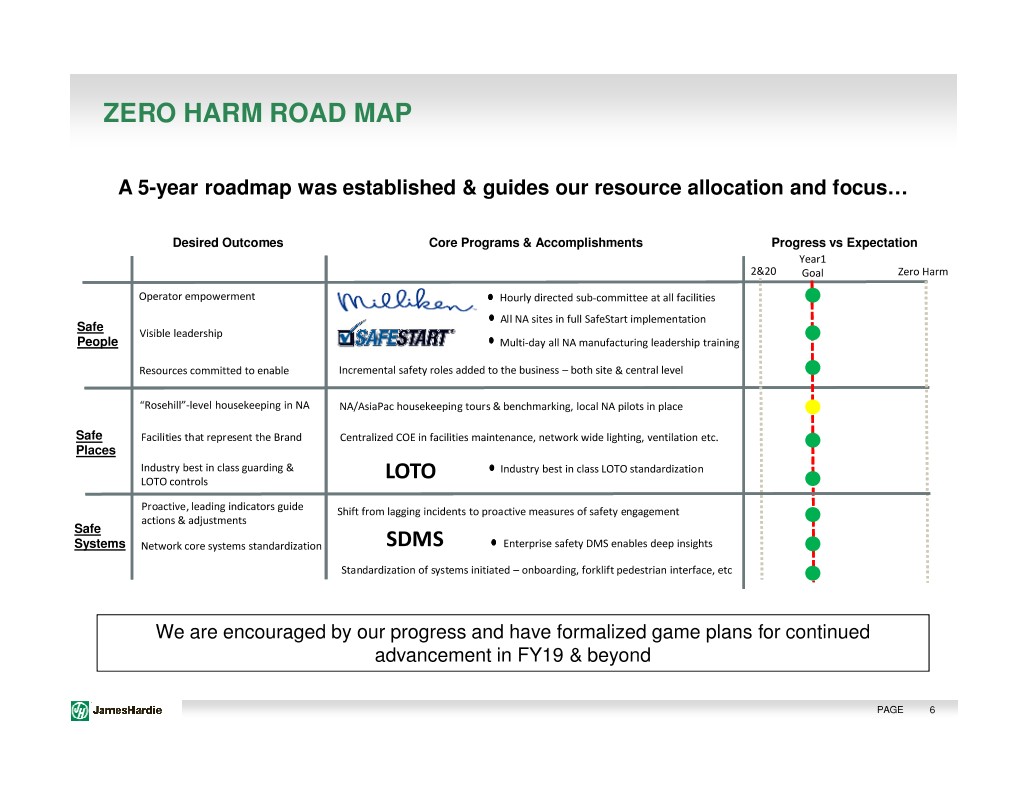

ZERO HARM ROAD MAP A 5-year roadmap was established & guides our resource allocation and focus… Desired Outcomes Core Programs & Accomplishments Progress vs Expectation Year1 2&20 Goal Zero Harm Operator empowerment Hourly directed sub-committee at all facilities All NA sites in full SafeStart implementation Safe Visible leadership People Multi-day all NA manufacturing leadership training Resources committed to enable Incremental safety roles added to the business – both site & central level “Rosehill”-level housekeeping in NA NA/AsiaPac housekeeping tours & benchmarking, local NA pilots in place Safe Facilities that represent the Brand Centralized COE in facilities maintenance, network wide lighting, ventilation etc. Places Industry best in class guarding & Industry best in class LOTO standardization LOTO controls LOTO Proactive, leading indicators guide Shift from lagging incidents to proactive measures of safety engagement actions & adjustments Safe Systems Network core systems standardization SDMS Enterprise safety DMS enables deep insights Standardization of systems initiated – onboarding, forklift pedestrian interface, etc We are encouraged by our progress and have formalized game plans for continued advancement in FY19 & beyond PAGE 6

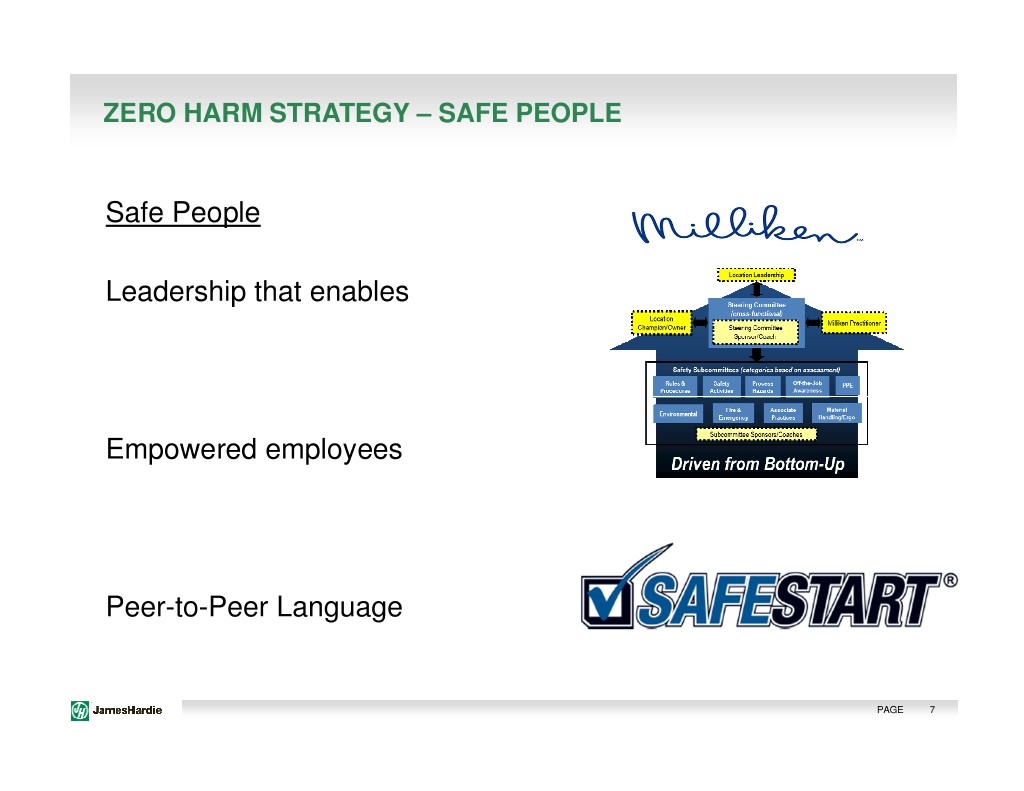

ZERO HARM STRATEGY – SAFE PEOPLE Safe People Leadership that enables Empowered employees Peer-to-Peer Language PAGE 7

ZERO HARM STRATEGY – PLACES & SYSTEMS Safe Places Zero Harm integrated design Facilities that represent our brand Safe Systems Global best practice sharing World class benchmarking PAGE 8

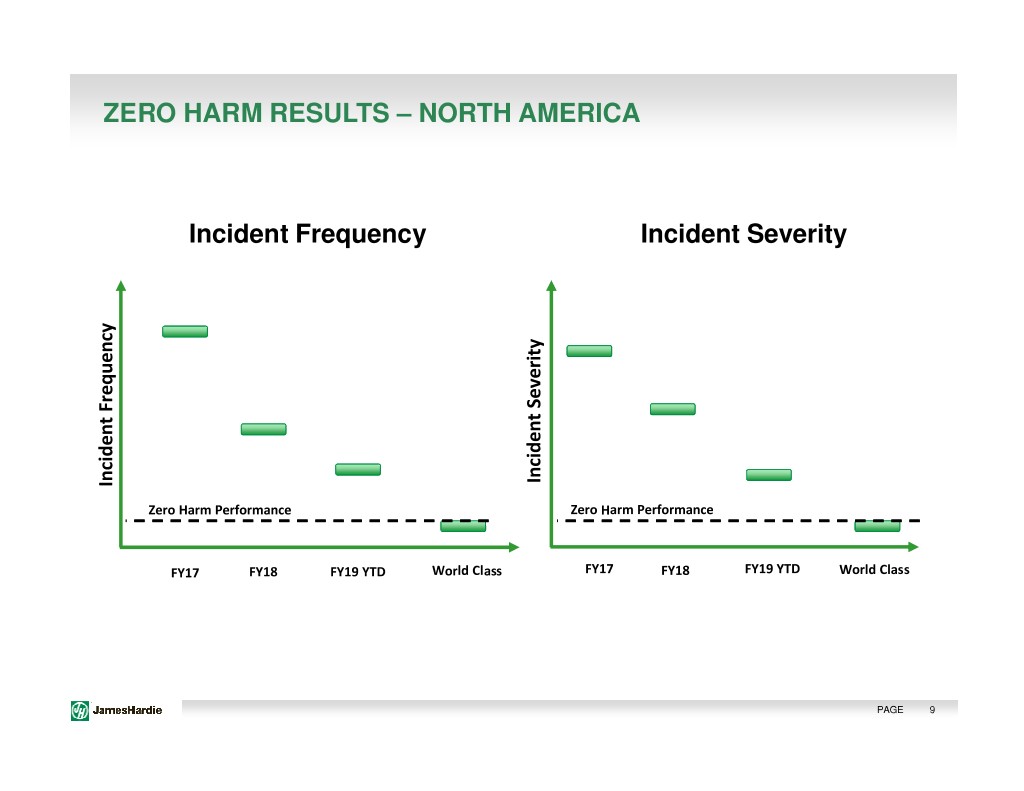

ZERO HARM RESULTS – NORTH AMERICA Incident Frequency Incident Severity Incident Incident Severity Incident Incident Frequency Zero Harm Performance Zero Harm Performance FY17 FY18 FY19 YTD World Class FY17 FY18 FY19 YTD World Class PAGE 9

ZERO HARM – GLOBAL DEPLOYMENT We are leveraging our global resources & applying a universal approach to our Zero Harm strategy PAGE 10

KEY TAKEAWAYS • JH organization is highly committed to journey to world class safety performance • Work force empowerment & leadership engagement are critical to our Zero Harm strategy • Global integration is occurring & best practice sharing is raising the standard in all regions • We are pleased by year one progress & have a roadmap for future direction PAGE 11

• Xxx • Xxx Q&A