Exhibit 99.3 Zero Harm & Lean Transformation Ryan1 Kilcullen, EVP - Operations

AGENDA Zero Harm Foundation Lean Transformation Alabama Construction Update 2

AGENDA Zero Harm Foundation Lean Transformation Alabama Construction Update 3

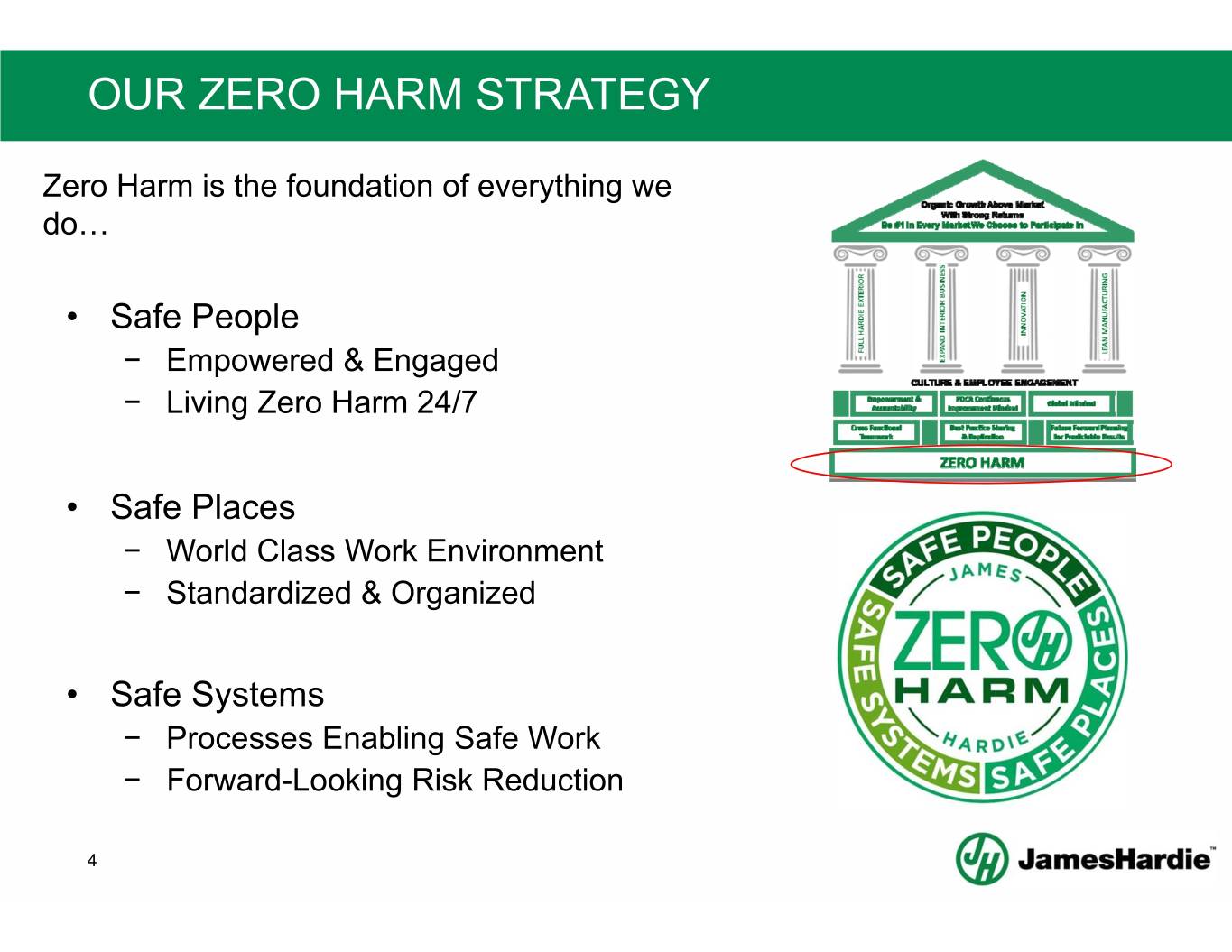

OUR ZERO HARM STRATEGY Zero Harm is the foundation of everything we do… • Safe People − Empowered & Engaged − Living Zero Harm 24/7 • Safe Places − World Class Work Environment − Standardized & Organized • Safe Systems − Processes Enabling Safe Work − Forward-Looking Risk Reduction 4

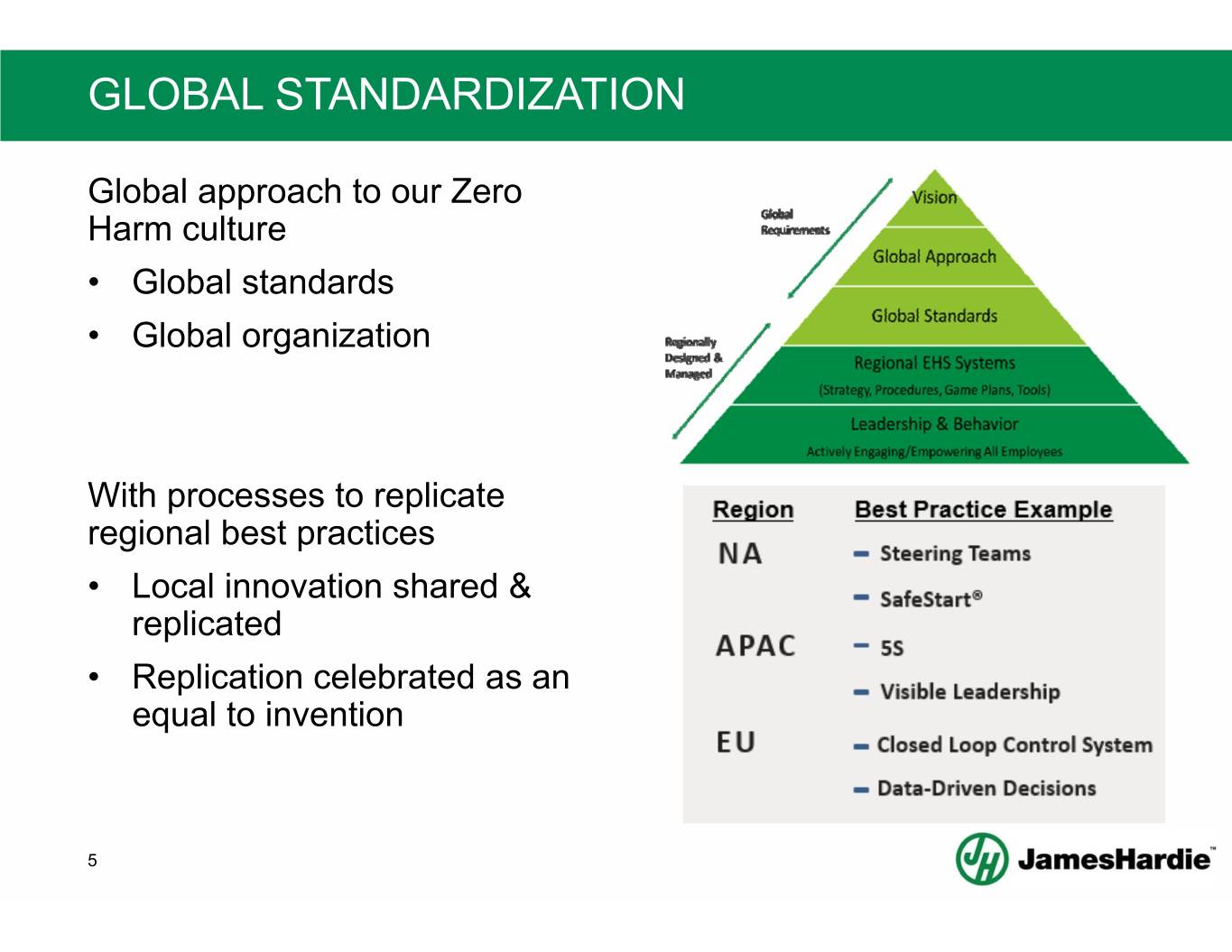

GLOBAL STANDARDIZATION Global approach to our Zero Harm culture • Global standards • Global organization With processes to replicate regional best practices • Local innovation shared & replicated • Replication celebrated as an equal to invention 5

SAFE PEOPLE – LEADERSHIP COMMITMENT Oversight at ELT level • Prattville construction pause Significant investment • 20+ incremental global safety professionals since FY17 • Investment in safety data management system, training, facilities upgrades, etc. 6

SAFE PEOPLE – GLOBAL MINDSET Improve, Standardize, Replicate – on a global scale – PPE example Before After (Europe) (Europe) 7

SAFE PLACES – GLOBAL MINDSET • One JH standard in our plants accelerates best practice replication • Global best practices, benchmarked to world class levels, with strong local ownership − 5S replication – standardization − Pedestrian/Forklift standardization leads global improvement team Before After North America North America APAC 8

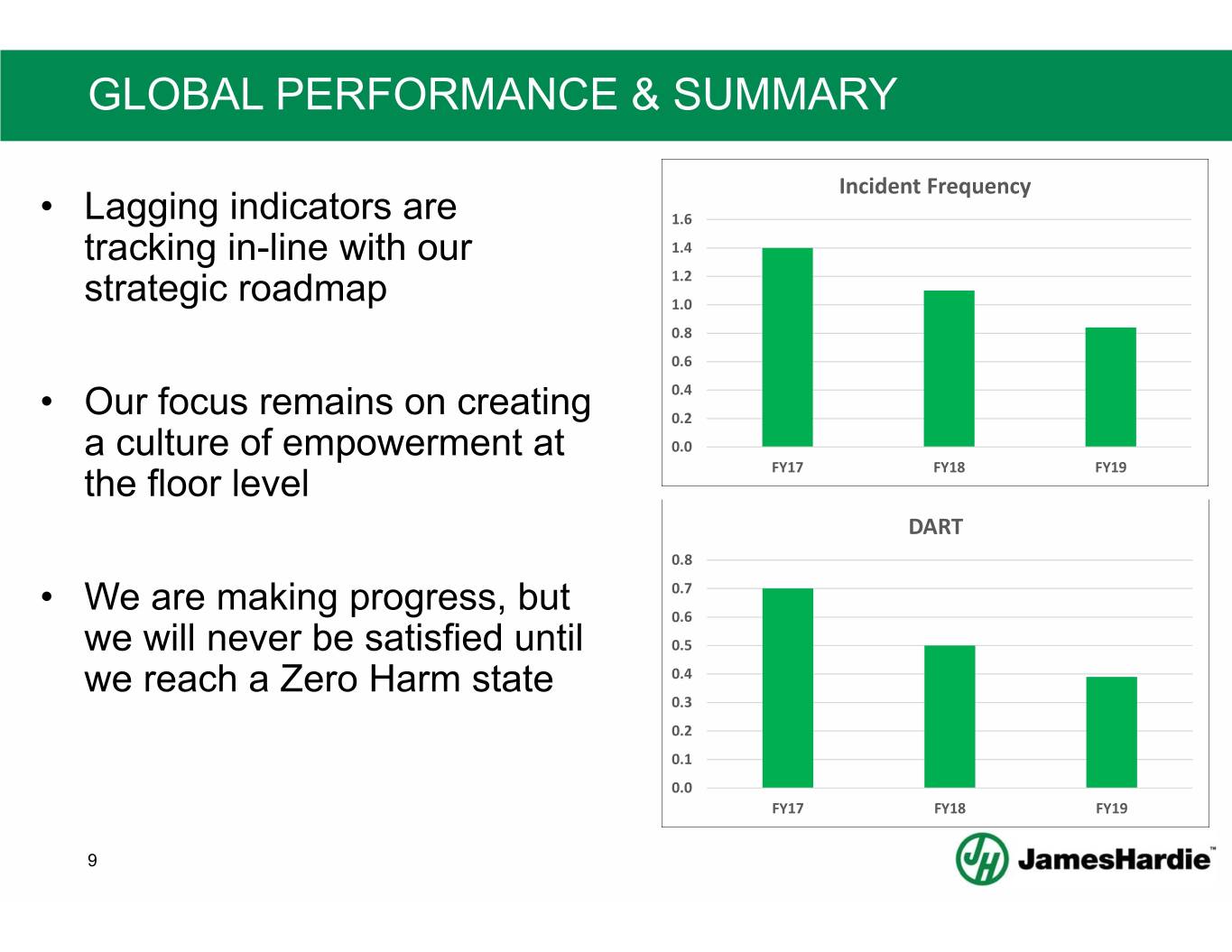

GLOBAL PERFORMANCE & SUMMARY Incident Frequency • Lagging indicators are 1.6 tracking in-line with our 1.4 1.2 strategic roadmap 1.0 0.8 0.6 0.4 • Our focus remains on creating 0.2 a culture of empowerment at 0.0 the floor level FY17 FY18 FY19 DART 0.8 0.7 • We are making progress, but 0.6 we will never be satisfied until 0.5 we reach a Zero Harm state 0.4 0.3 0.2 0.1 0.0 FY17 FY18 FY19 9

ZERO HARM SUMMARY • Zero Harm is the foundation of everything we do • Strong leadership commitment • Operators are empowered & engaged to live Zero Harm 24/7 • We are making good progress, but will never be satisfied until true Zero Harm is achieved • Zero Harm fundamentals are at the core of how we operate 10

AGENDA Zero Harm Foundation Lean Transformation Alabama Construction Update 11

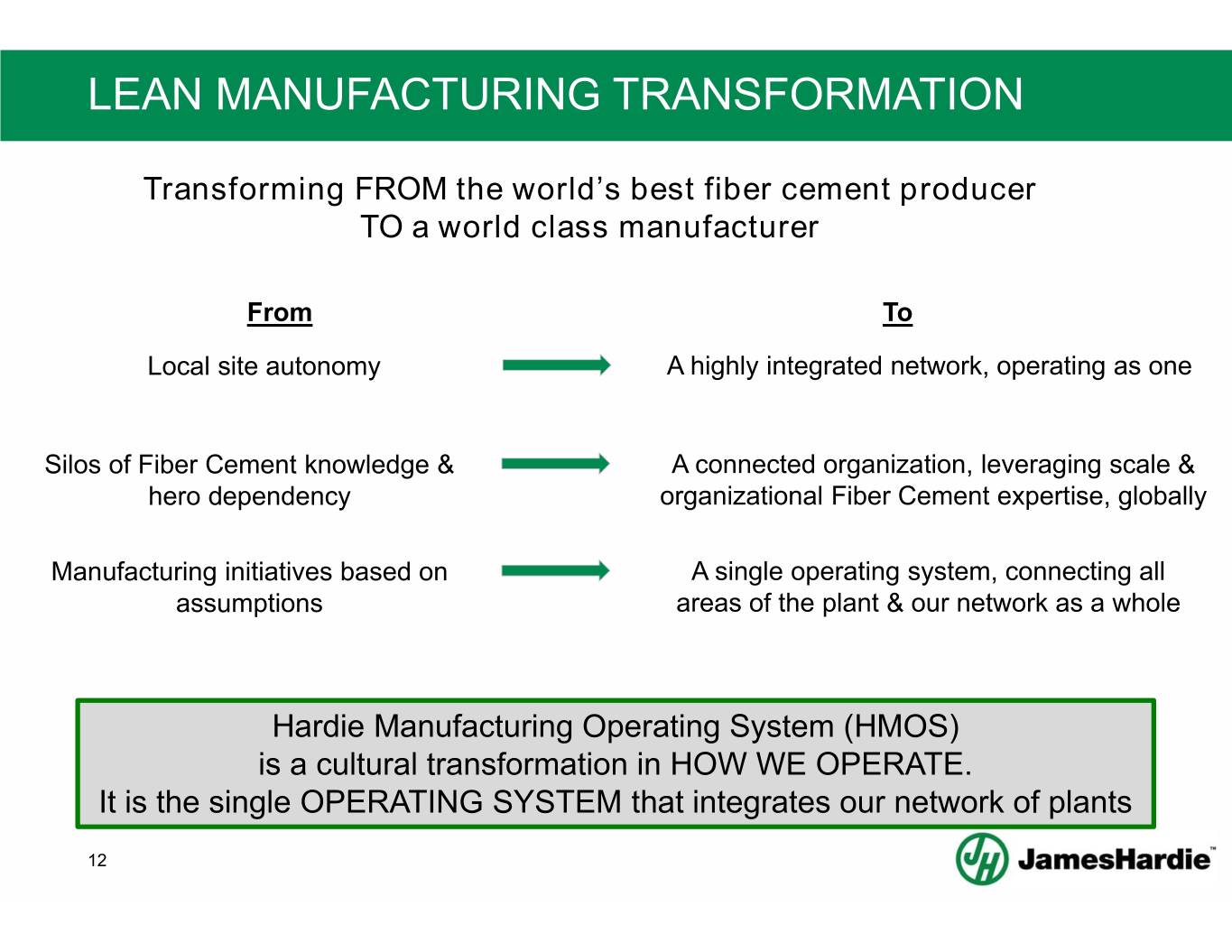

LEAN MANUFACTURING TRANSFORMATION Transforming FROM the world’s best fiber cement producer TO a world class manufacturer From To Local site autonomy A highly integrated network, operating as one Silos of Fiber Cement knowledge & A connected organization, leveraging scale & hero dependency organizational Fiber Cement expertise, globally Manufacturing initiatives based on A single operating system, connecting all assumptions areas of the plant & our network as a whole Hardie Manufacturing Operating System (HMOS) is a cultural transformation in HOW WE OPERATE. It is the single OPERATING SYSTEM that integrates our network of plants 12

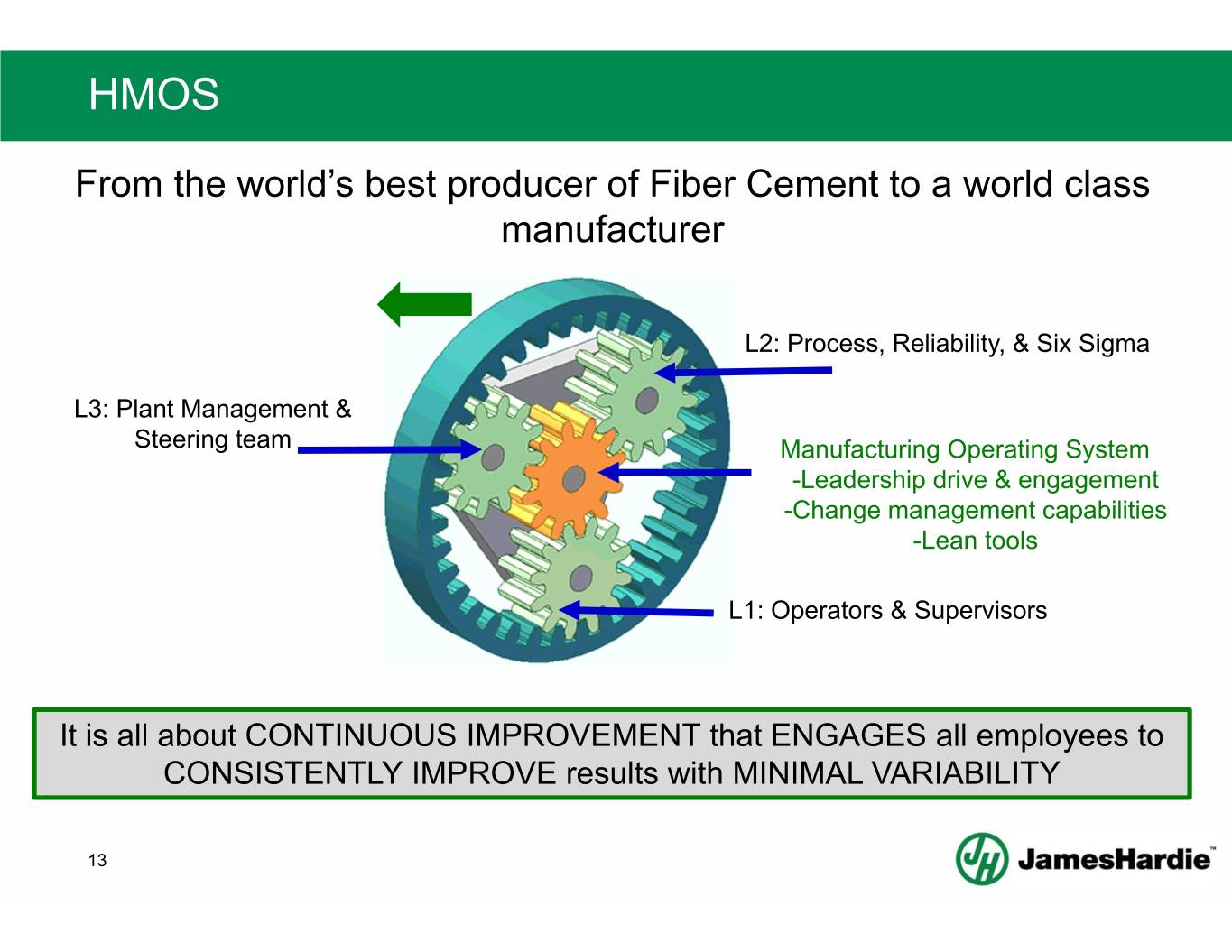

HMOS From the world’s best producer of Fiber Cement to a world class manufacturer L2: Process, Reliability, & Six Sigma L3: Plant Management & Steering team Manufacturing Operating System -Leadership drive & engagement -Change management capabilities -Lean tools L1: Operators & Supervisors It is all about CONTINUOUS IMPROVEMENT that ENGAGES all employees to CONSISTENTLY IMPROVE results with MINIMAL VARIABILITY 13

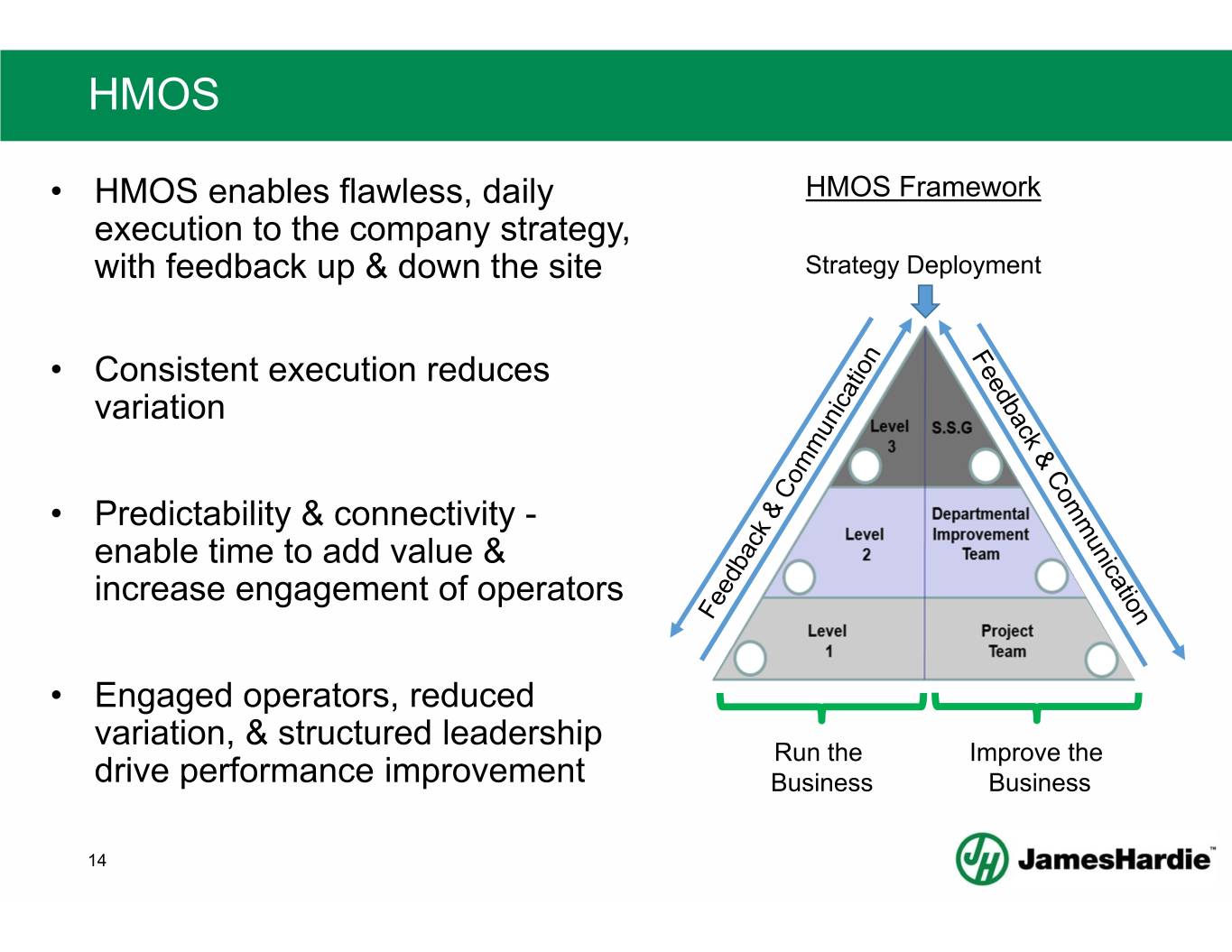

HMOS • HMOS enables flawless, daily HMOS Framework execution to the company strategy, with feedback up & down the site Strategy Deployment • Consistent execution reduces variation • Predictability & connectivity - enable time to add value & increase engagement of operators • Engaged operators, reduced variation, & structured leadership Run the Improve the drive performance improvement Business Business 14

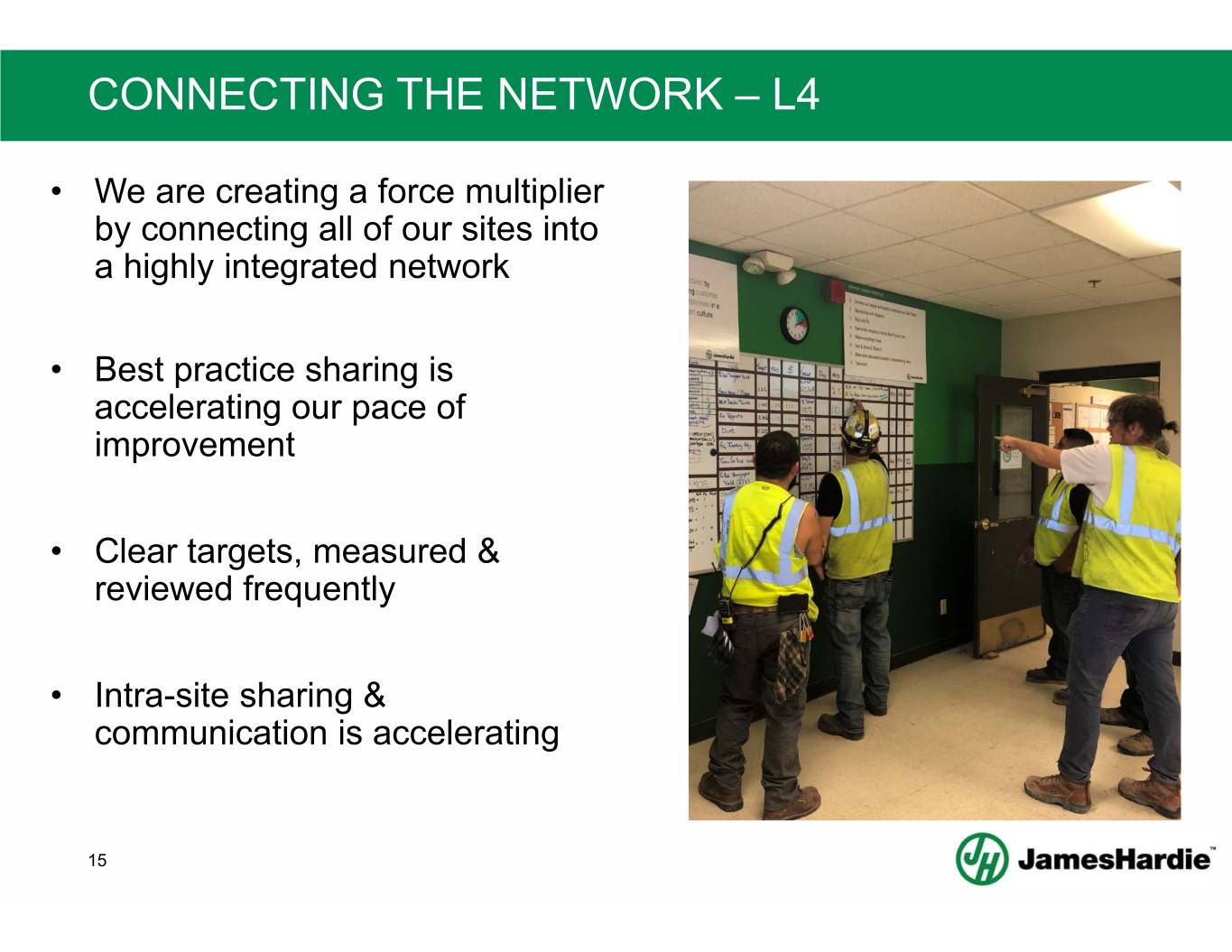

CONNECTING THE NETWORK – L4 • We are creating a force multiplier by connecting all of our sites into a highly integrated network • Best practice sharing is accelerating our pace of improvement • Clear targets, measured & reviewed frequently • Intra-site sharing & communication is accelerating Prattville, AL 15

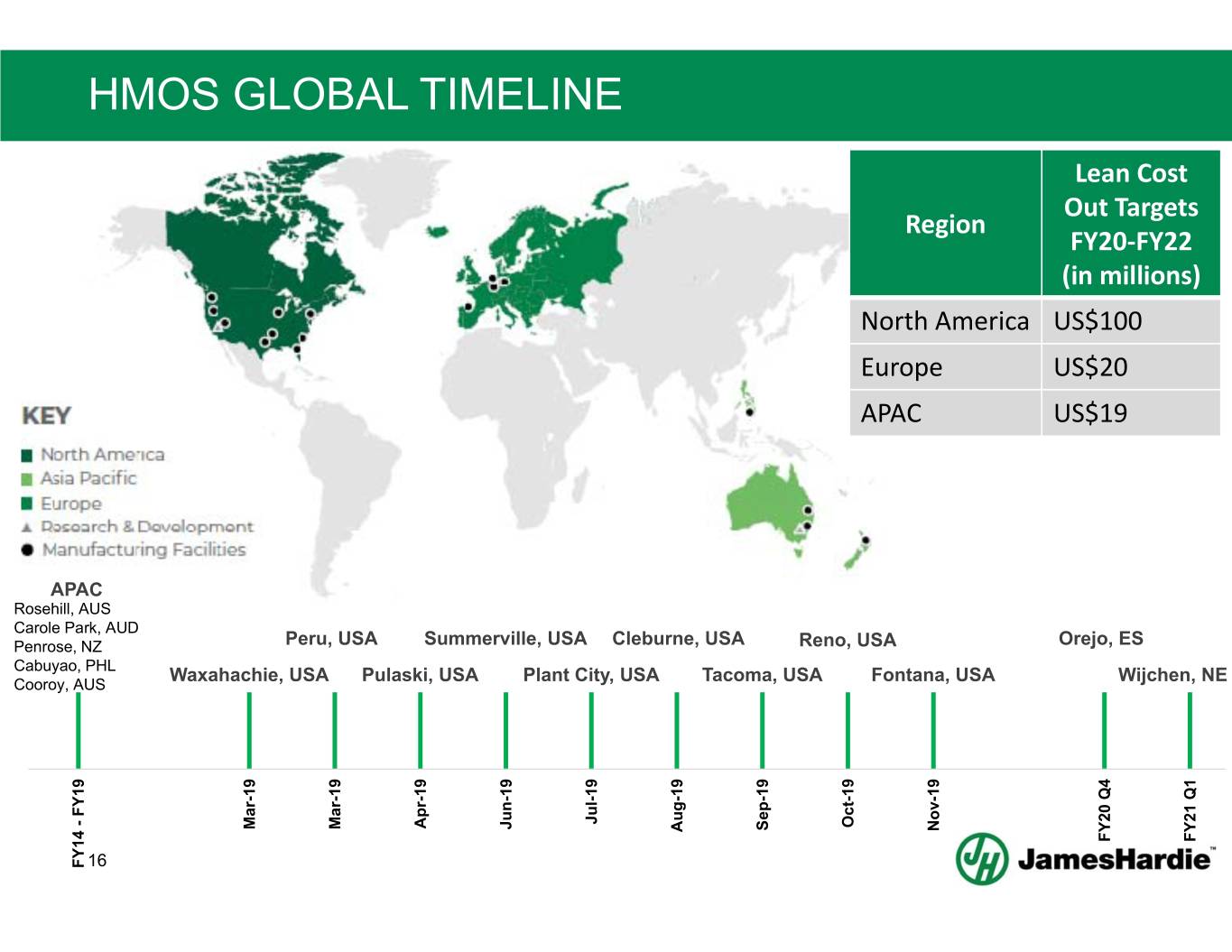

HMOS GLOBAL TIMELINE Lean Cost Out Targets Region FY20‐FY22 (in millions) North America US$100 Europe US$20 APAC US$19 APAC Rosehill, AUS Carole Park, AUD Penrose, NZ Peru, USA Summerville, USA Cleburne, USA Reno, USA Orejo, ES Cabuyao, PHL Waxahachie, USA Pulaski, USA Plant City, USA Tacoma, USA Fontana, USA Wijchen, NE Cooroy, AUS Jul-19 Oct-19 Apr-19 Jun-19 Mar-19 Mar-19 Sep-19 Nov-19 Aug-19 FY20 Q4 FY21 Q1 FY14 FY19 - 16

GETTING STARTED – THE POWER OF GEMBA • Leverage learnings from APAC and generate excitement in NA − 40+ NA employees GEMBA to APAC (Feb & May 2019) • Lay the groundwork for future deployment in Europe − 15 EU manufacturing employees GEMBA to NA (Jul 2019) • Replicate & Improve − APAC GEMBA to NA to learn, share best practice and replicate (Oct 2019) North America in APAC Europe in North America GEMBA with purpose 17

ORGANIZATIONAL CAPABILITY Significant investments in organizational capability to enable the transformation… • NA Lean VP with a team of 10 Lean professionals • Lean roles created at all of our manufacturing facilities • All 2,000+ NA manufacturing employees will be trained in Lean by end of this fiscal year • Currently building out EU Lean organization 18

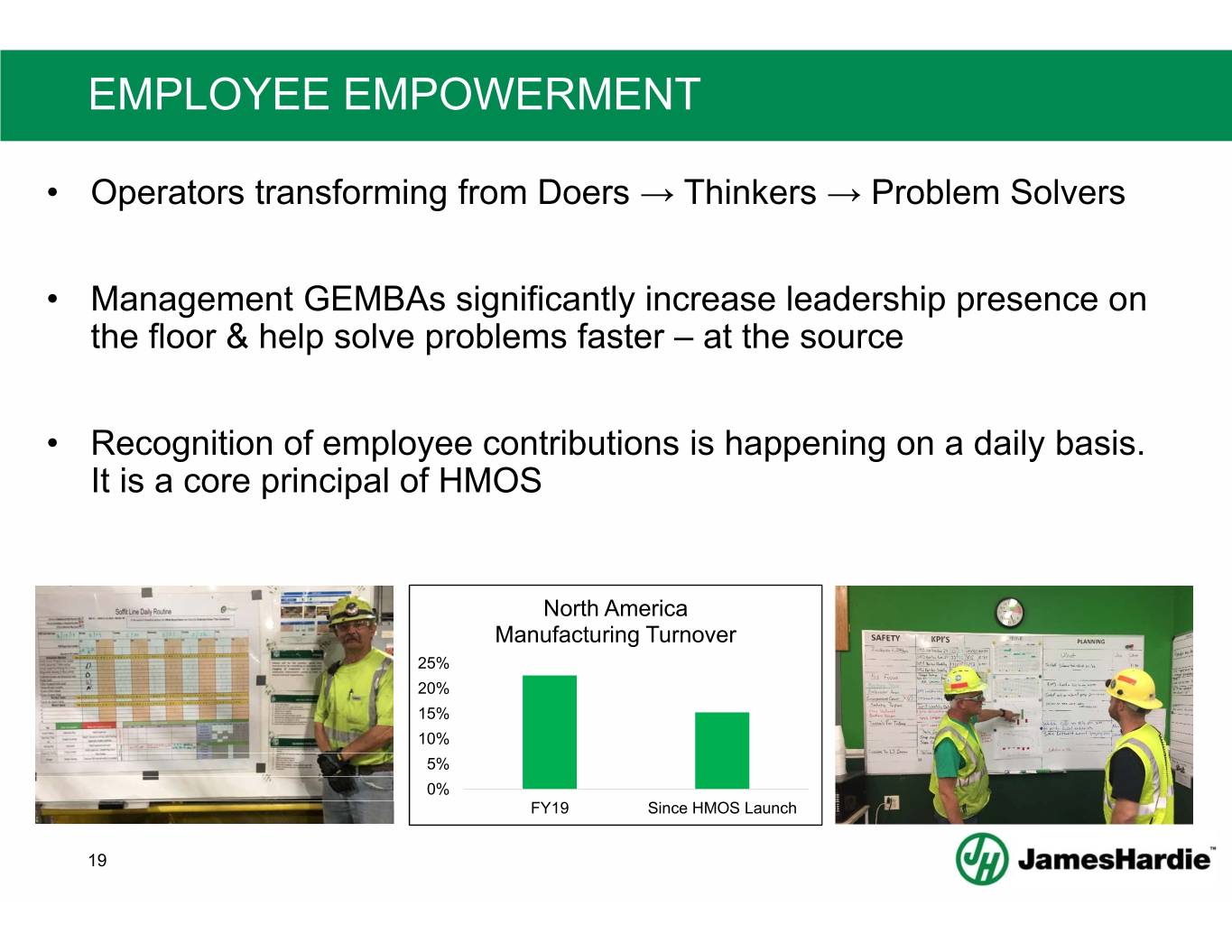

EMPLOYEE EMPOWERMENT • Operators transforming from Doers → Thinkers → Problem Solvers • Management GEMBAs significantly increase leadership presence on the floor & help solve problems faster – at the source • Recognition of employee contributions is happening on a daily basis. It is a core principal of HMOS North America Manufacturing Turnover 25% 20% 15% 10% 5% 0% FY19 Since HMOS Launch 19

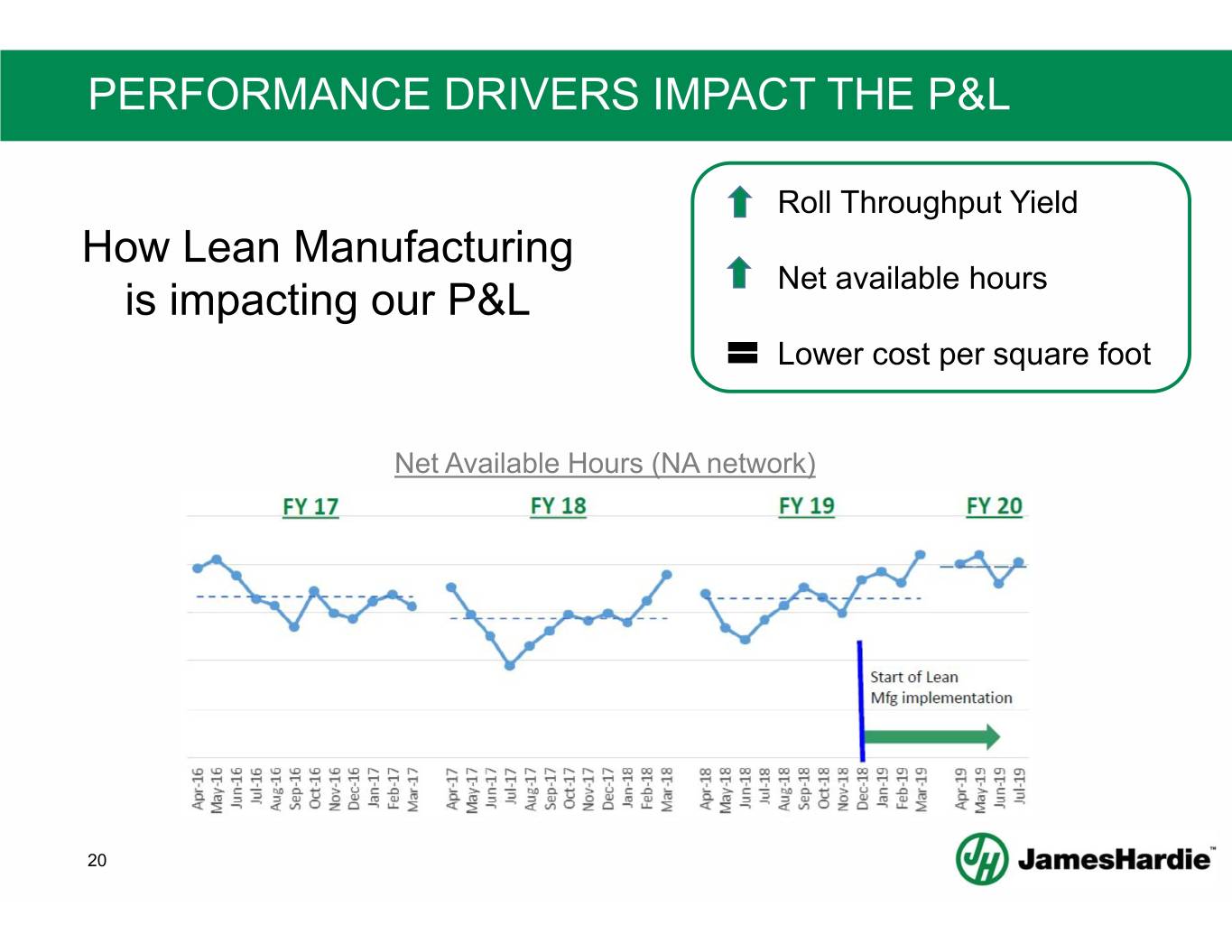

PERFORMANCE DRIVERS IMPACT THE P&L Roll Throughput Yield How Lean Manufacturing Net available hours is impacting our P&L Lower cost per square foot Net Available Hours (NA network) 20

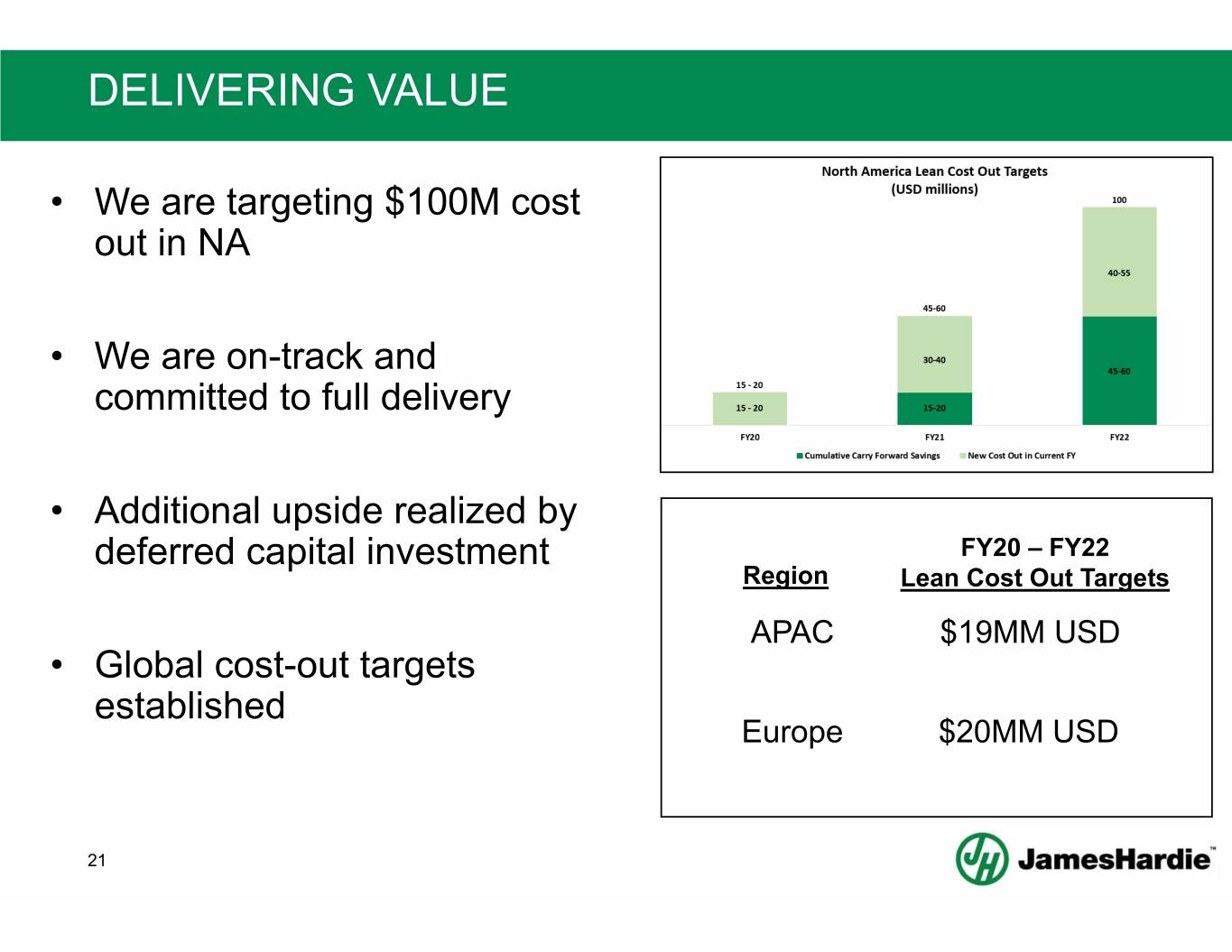

DELIVERING VALUE • We are targeting $100M cost out in NA • We are on-track and committed to full delivery • Additional upside realized by deferred capital investment FY20 – FY22 Region Lean Cost Out Targets APAC $19MM USD • Global cost-out targets established Europe $20MM USD 21

LEAN SUMMARY – THE JOURNEY NEVER ENDS • We are on-track to implement HMOS in all 9 NA plants by the end of Q3 FY20 • Employee engagement is improving • We are on-track to deliver our $100MM cost-out target in NA • We are forward-looking in our approach & see significant opportunity through lean deployment in our plants & overall value chain • Leadership engagement & employee commitment will be critical in everything we do 22

AGENDA Zero Harm Foundation Lean Transformation Alabama Construction Update 23

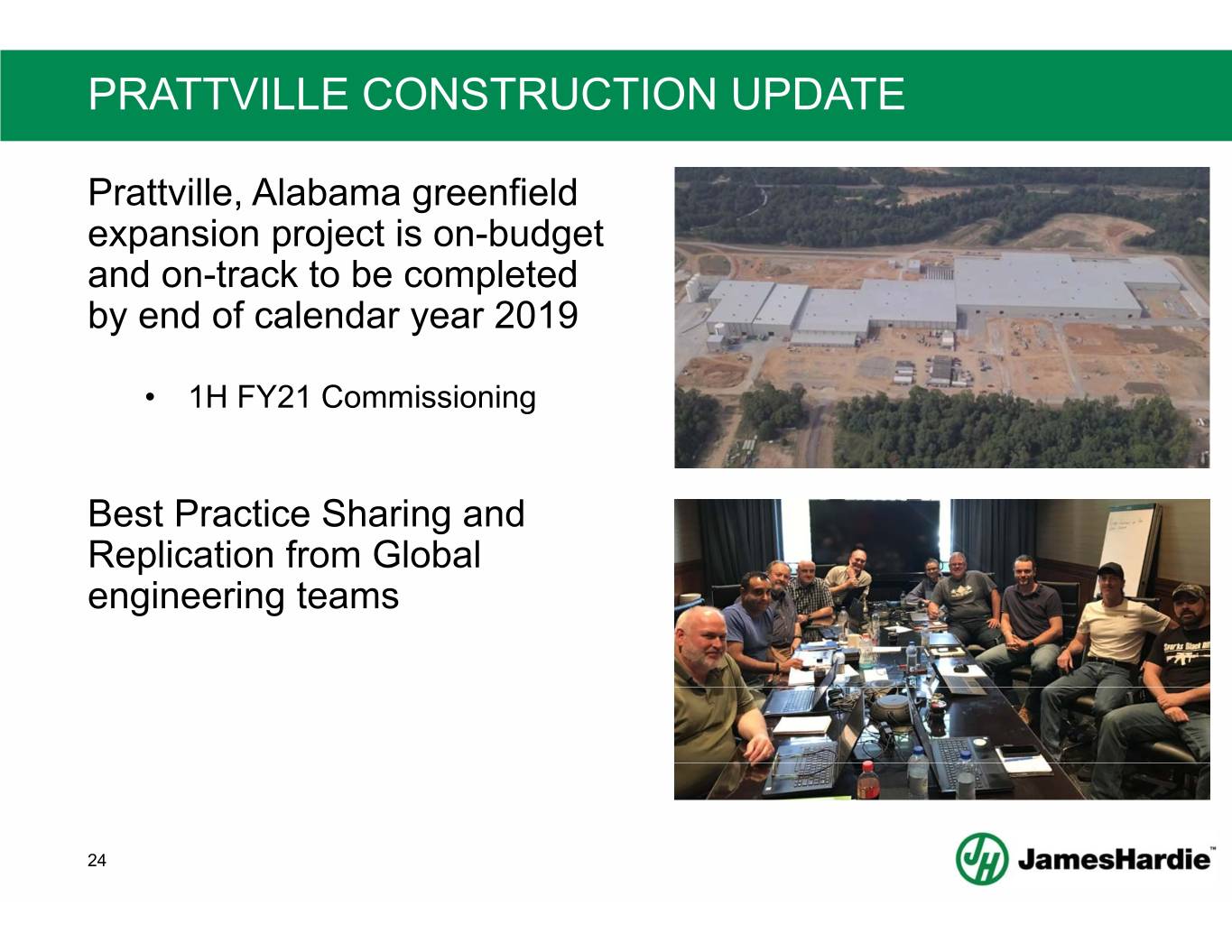

PRATTVILLE CONSTRUCTION UPDATE Prattville, Alabama greenfield expansion project is on-budget and on-track to be completed by end of calendar year 2019 • 1H FY21 Commissioning Best Practice Sharing and Replication from Global engineering teams 24

SUMMARY • Zero Harm is the foundation of everything we do • HMOS is a cultural transformation in how we operate. It connects our sites & our network as one JH operating system • Employee engagement is improving • Lean savings commitment is on-track • Alabama construction is on-track 25