Sustainability Report Fiscal Year 2021 Published 28 July 2021 Building Sustainable Communities Exhibit 99.3

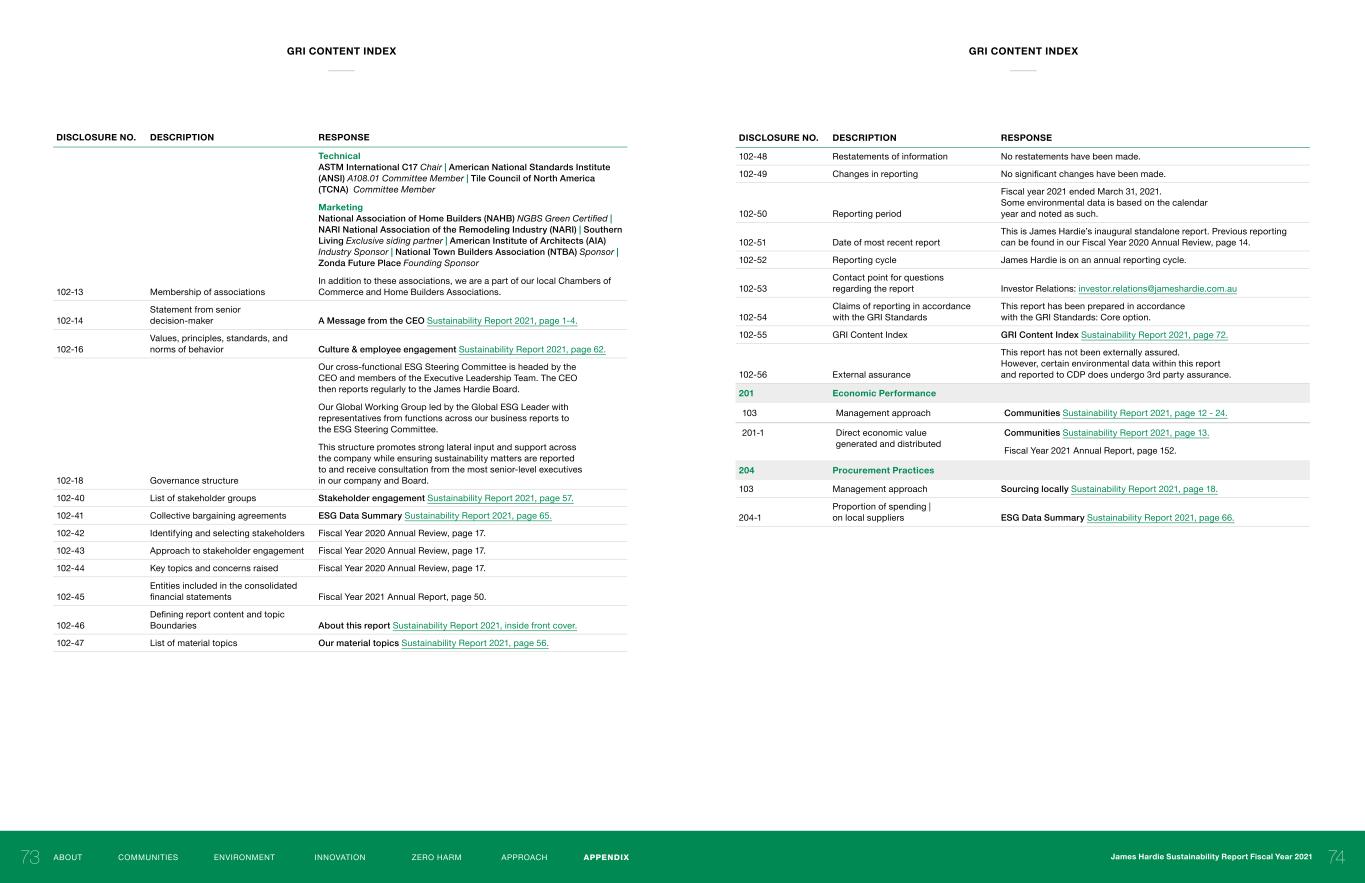

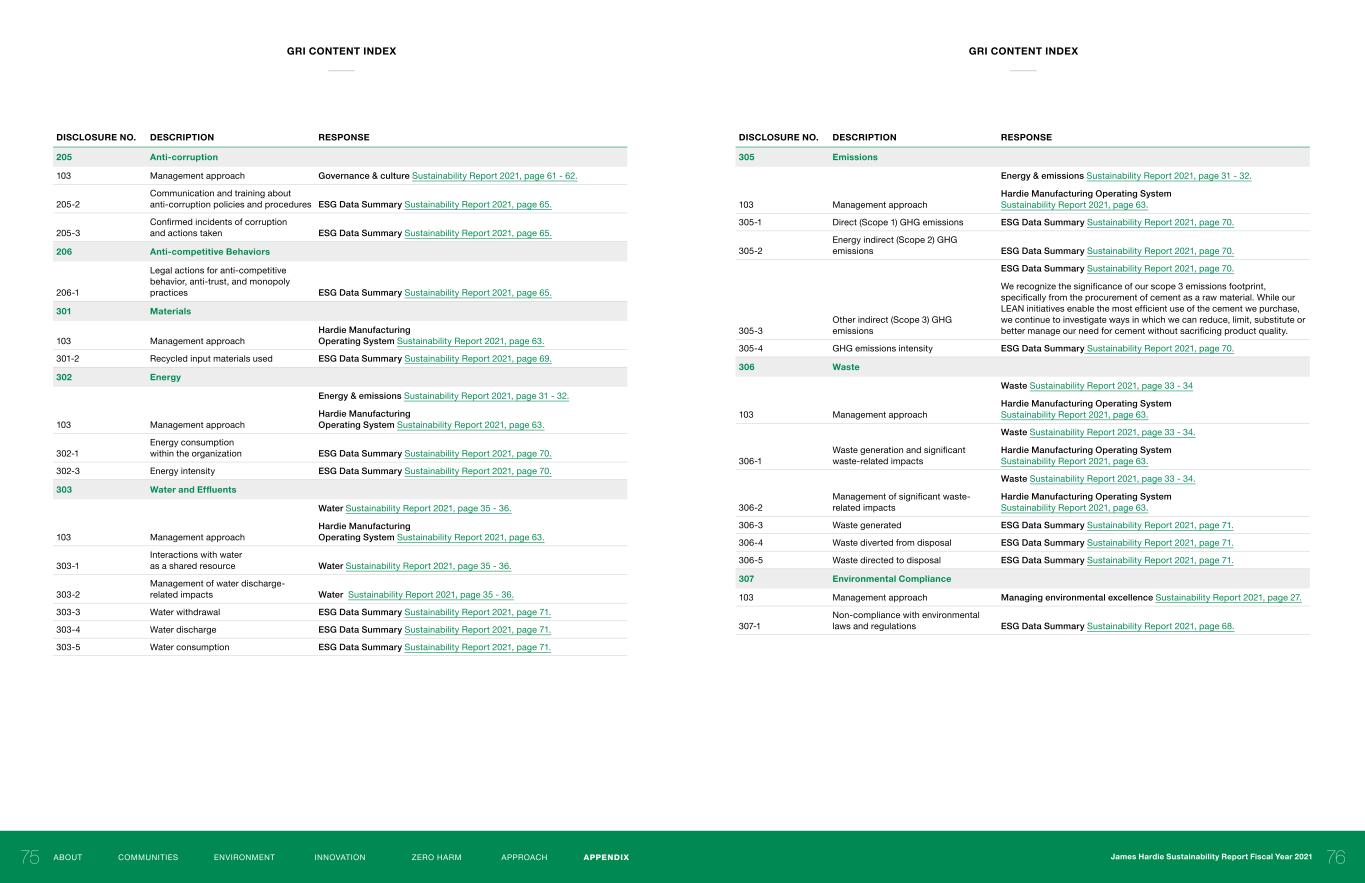

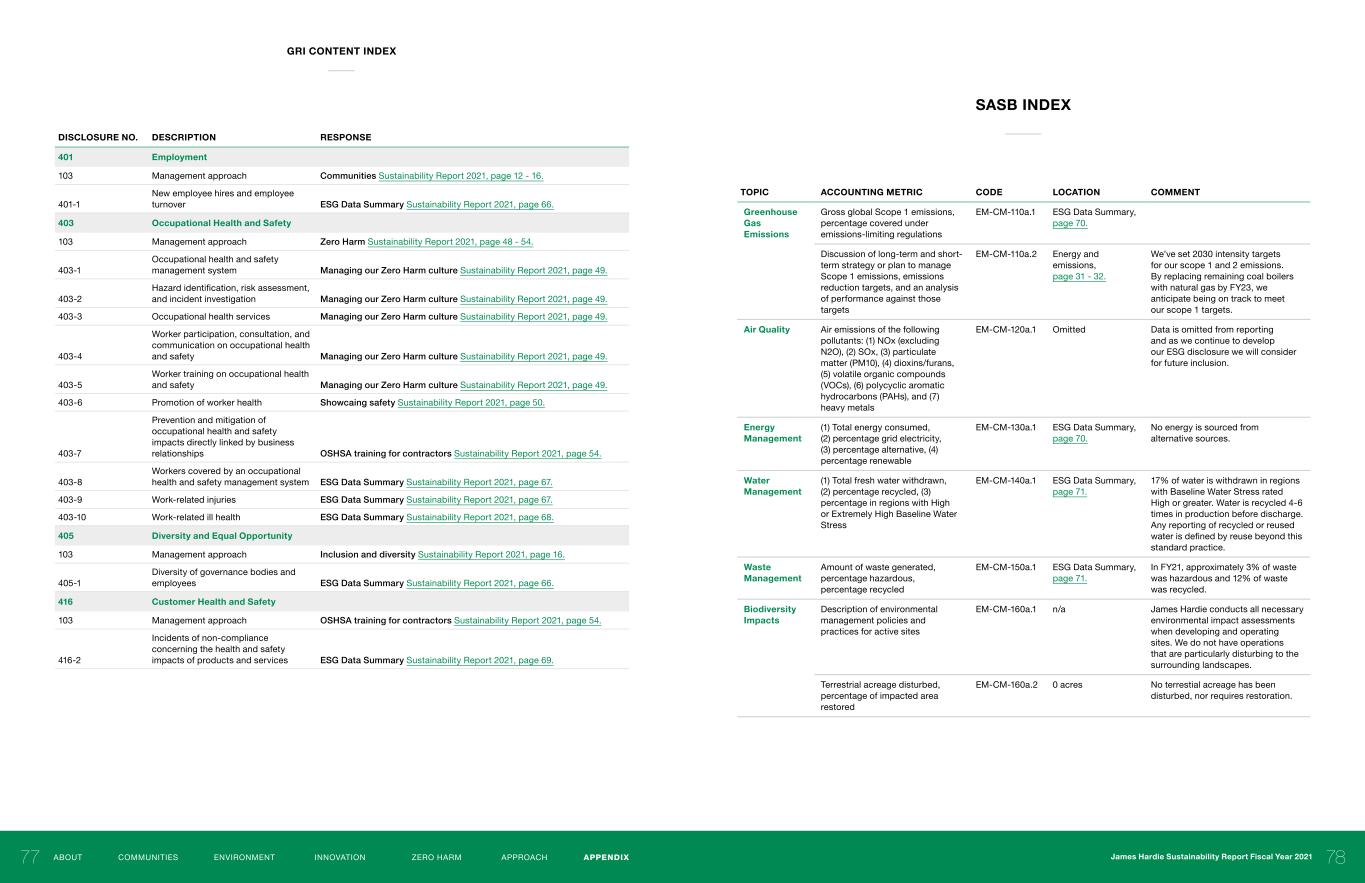

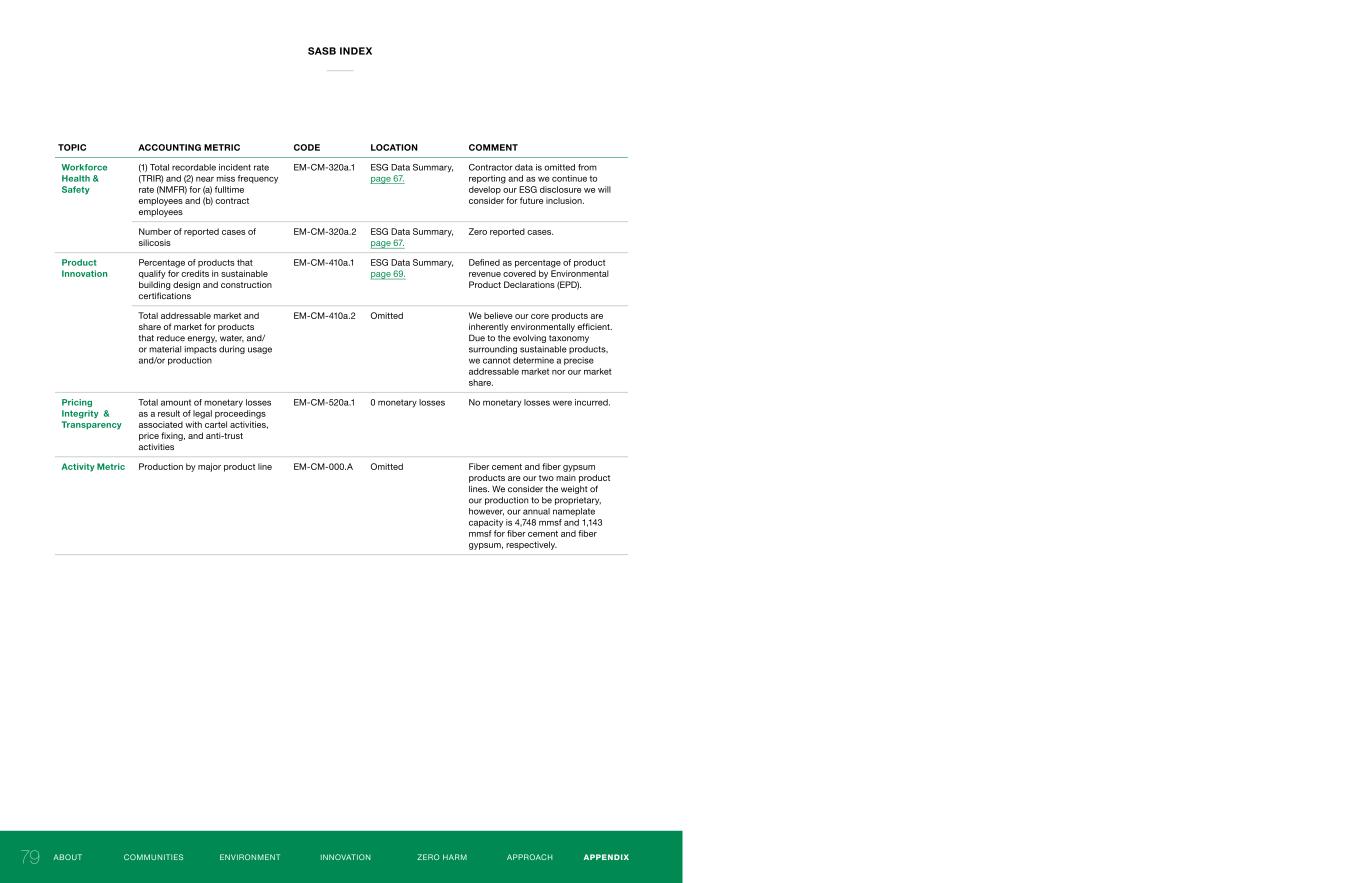

About A MESSAGE FROM THE CEO 1-4 OPERATIONS OVERVIEW 5-6 FY21 HIGHLIGHTS 7-8 BUILDING SUSTAINABLE COMMUNITIES 9-10 Our pillars COMMUNITIES 11-24 ENVIRONMENT 25-36 INNOVATION 37-46 ZERO HARM 47-54 Approach OUR STAKEHOLDERS & MATERIAL TOPICS 55-58 BUSINESS RESILIENCE 59-60 GOVERNANCE & CULTURE 61-64 Appendix ESG DATA SUMMARY 65-71 GRI CONTENT INDEX 72-76 SASB INDEX 78-79 CONTENTS About James Hardie James Hardie Industries plc is the world’s #1 producer and marketer of high-performance fiber cement exterior and interior products and a market leader in Europe for fiber gypsum products. Our company culture is built on providing a foundation of “Zero Harm,” creating a positive impact in communities, and delivering environmentally-responsible, innovative solutions to customers. Our durable, low maintenance, and innovative products are made mostly from natural and sustainable raw materials, delivering endless possibilities of design and aesthetics to consumers (homeowners). We manufacture a variety of patterned profiles and surface finishes for a range of applications, including external siding, trim, soffit lining, internal linings, walls, facades, floors and tile underlay for use in residential, commercial and industrial applications. We manufacture and distribute our products and accessories globally for use in new residential construction, manufactured housing, renovations, and extensions, as well as a variety of commercial and industrial applications. Headquartered in Ireland, James Hardie employs a diverse global workforce of approximately 4,800 employees across operations in North America, Europe, Australia, New Zealand and the Philippines. In the fiscal year ended 31 March 2021 (FY21), James Hardie generated more than $2.9 billion in net sales and more than $458 million in adjusted net income. About this report This is James Hardie’s first full sustainability report. It covers our sustainability performance progress for FY21 across our global operations and also highlights our future priorities. It has been prepared in accordance with GRI Standards: Core option. This milestone represents and captures the significant efforts we have made on our sustainability journey during the year. As our sustainability program progresses, we are committed to aligning with best-practice reporting standards and frameworks, including those set forth by Global Reporting Initiative (GRI), the Sustainability Accounting Standards Board (SASB) and the Task Force on Climate-related Financial Disclosures (TCFD). All monetary figures are in US dollars.

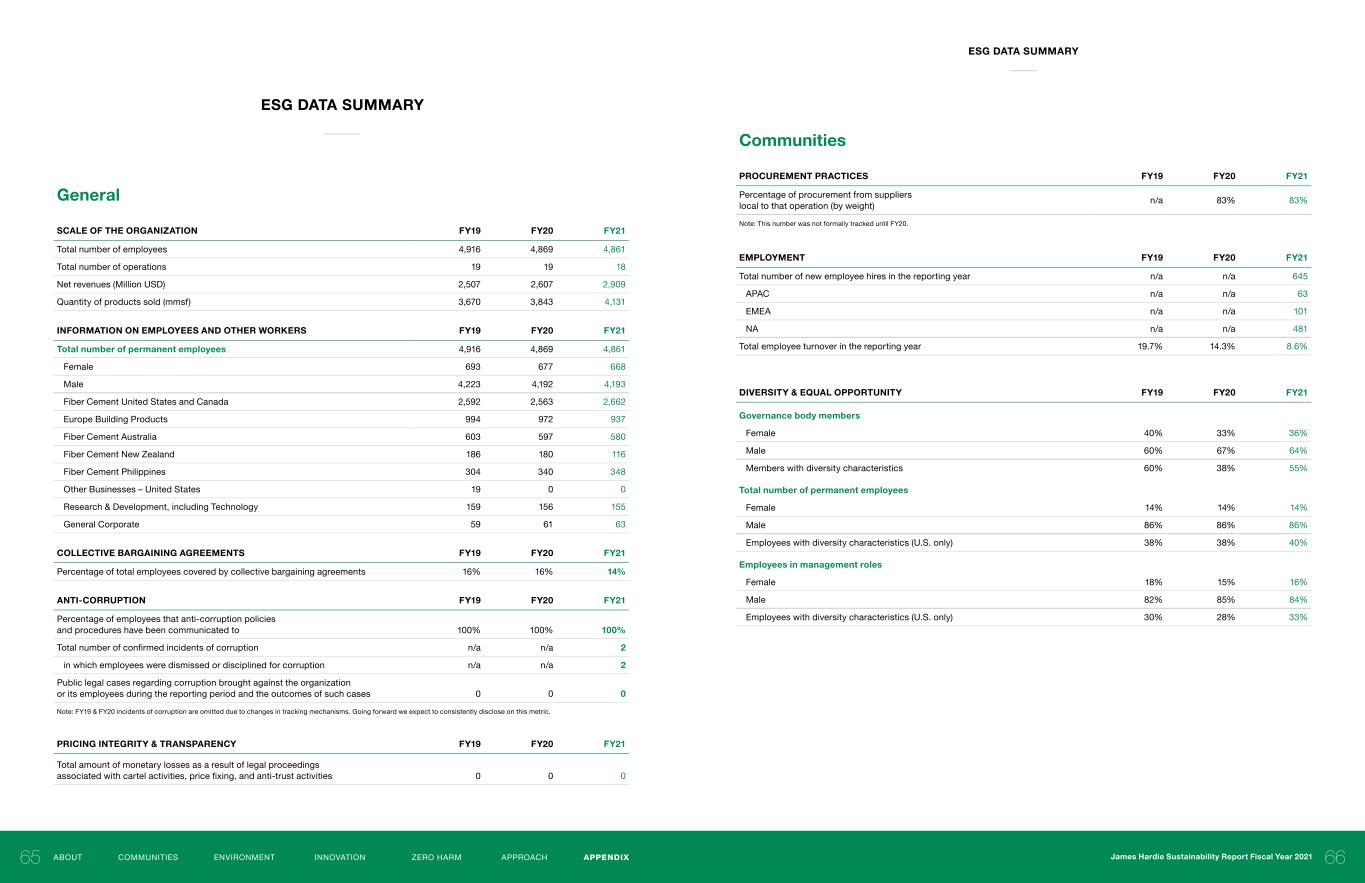

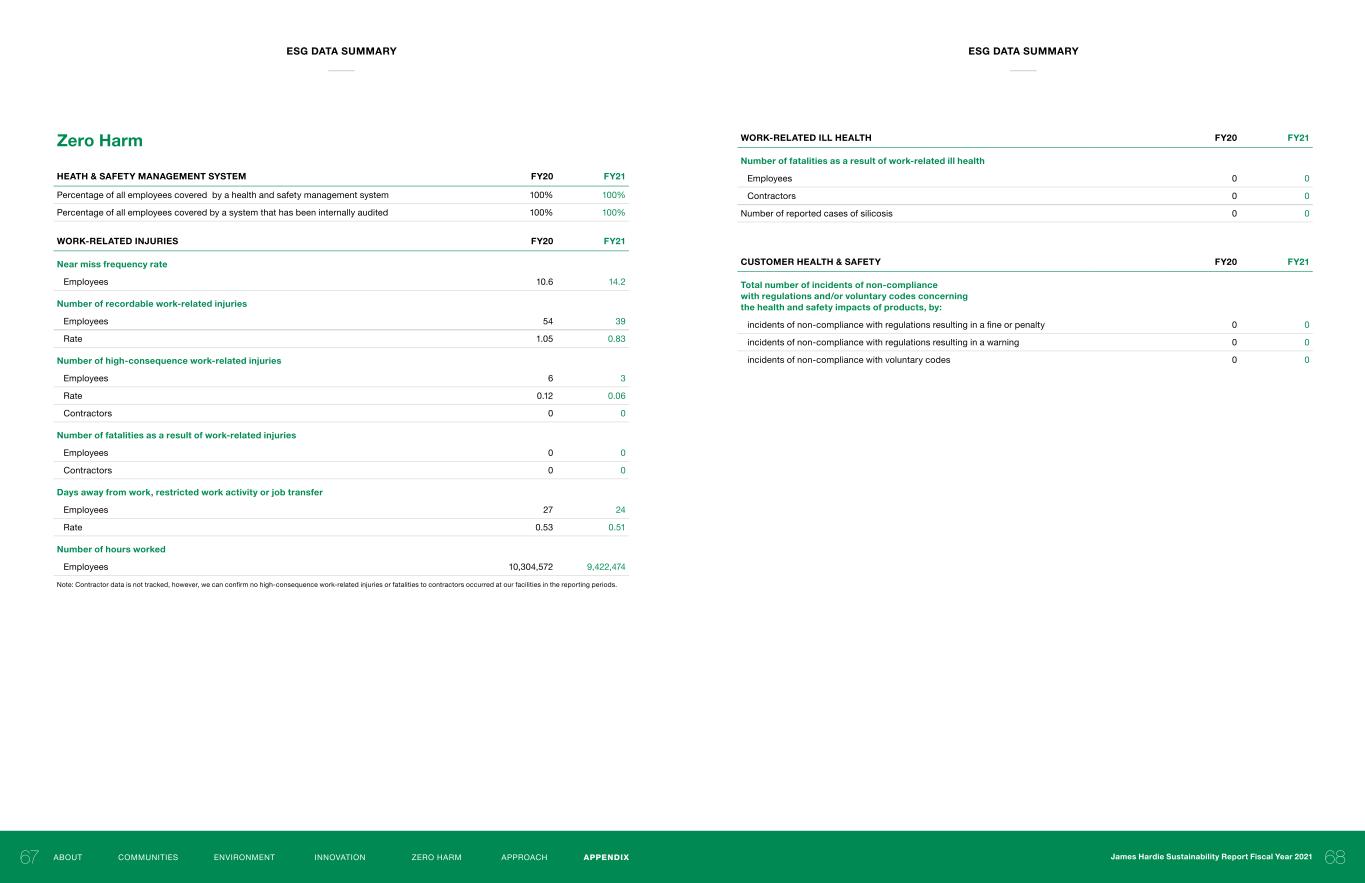

4.2 industry average FY 21 0.83 Community impact James Hardie Global impact Homeowner Co unity i pact Ja es Hardie Global i pact Ho eo ner OUR GOAL 80% of revenue from products with environmental product declarations OPERATE 3 Employee Resource Groups (ERGs) in North America FY 20 1.05 TRIR PERFORMANCE Total Recordable Incident Rate Building Sustainable Communities James Hardie is committed to building sustainable communities. This commitment is to: (i) the smallest of communities - the individual household, (ii) the James Hardie community, (iii) the local communities in which we live and operate, and (iv) the largest of all communities, the global ecosystem. We operate with a global mindset and at the same time take great care in how our business impacts households, our James Hardie community, and the local communities in which we live and operate. Building Better Homes Our business is about building better homes that have a lower impact on our environment and are built to last. We are part of the solution to the basic human need for shelter and do so in a way that more effectively maximizes the positive impact on our global community. Our products come with long warranties, with the majority being 30-year non-prorated warranties, illustrating our commitment to our products. This durability further translates into less maintenance over the product lifecycle giving that time back to the homeowner while also minimizing the impact on the environment. Our products protect the home against a variety of harsh climate conditions bringing the homeowner and their family peace of mind. Further, our products not only protect the home, they also help to beautify the home, bringing aesthetically pleasing designs to provide the homeowner a sense of pride and joy. This unique combination of aesthetically beautiful products with added durability and protection puts the homeowner’s mind at ease. Providing the market with products that help to build a better home is just a start. Through a continued investment in innovation, we strive to advance our ability to build better homes. We offer the market homebuilding materials of the future, which contribute to safer and more resilient homes while replacing other alternative materials that may be more harmful to our environment. To this end, we delivered three new products to the global market in May 2021, including Hardie® Textured Panels in the United States, HardieTM Fine Textured Cladding in Australia and Hardie® Brand VL Plank in Europe. These innovations provide the market with products that replace more labor intensive and environmentally harmful products. Our products are unique in the inherent sustainability benefits that they offer. We expect the market for our products to continue to grow and become more competitive as green homebuilding standards become the norm. We are well positioned to take advantage of this market shift but will need to continue to innovate and improve to ensure that our products remain the material of choice. At James Hardie, we aim to transform the way the world builds: better, safer, more beautifully and more sustainably. Building an Inclusive and Safe James Hardie Community We are focused on keeping our employees, our customers, and our suppliers safe inside our facilities and in their homes. Our goal is to ensure every employee returns home to their family safely at the end of every working day. We remain focused on our Zero Harm initiatives, working with the conviction that ‘every safety incident is preventable’. Our employees are a key part of the local communities in which we operate, and ensuring their safety helps to ensure the local community continues to thrive. In fiscal year 2021, we improved on our safety performance, reducing (and thus improving) our global incident rate (TRIR) by 21%. Our goal is to to continue to improve every day toward zero incidents. In addition to ensuring a safe James Hardie community, we are focused on building an inclusive and diverse James Hardie community; one that mirrors and reflects our local communities. In fiscal year 2021, we launched an Inclusion and Diversity committee focused on continually improving the James Hardie community in regard to inclusion and diversity. To remain an industry leader, we need to build a talent pipeline that engages with and seeks talent from typically underrepresented groups. Initiatives such as our Inclusion and Diversity Scholarship help to ensure that we we have a broad range of employee perspectives, strengthening our organization. We are building a James Hardie community that champions inclusion and diversity. We believe that starts at the top, with our Board of Directors. With 4 of 12 board members being female and 7 of 12 board members with diversity characteristics, we believe we are setting the right tone for the rest of our organization. At James Hardie, we are focused on building an inclusive and safe James Hardie community. 21 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX A MESSAGE FROM THE CEOA MESSAGE FROM THE CEO

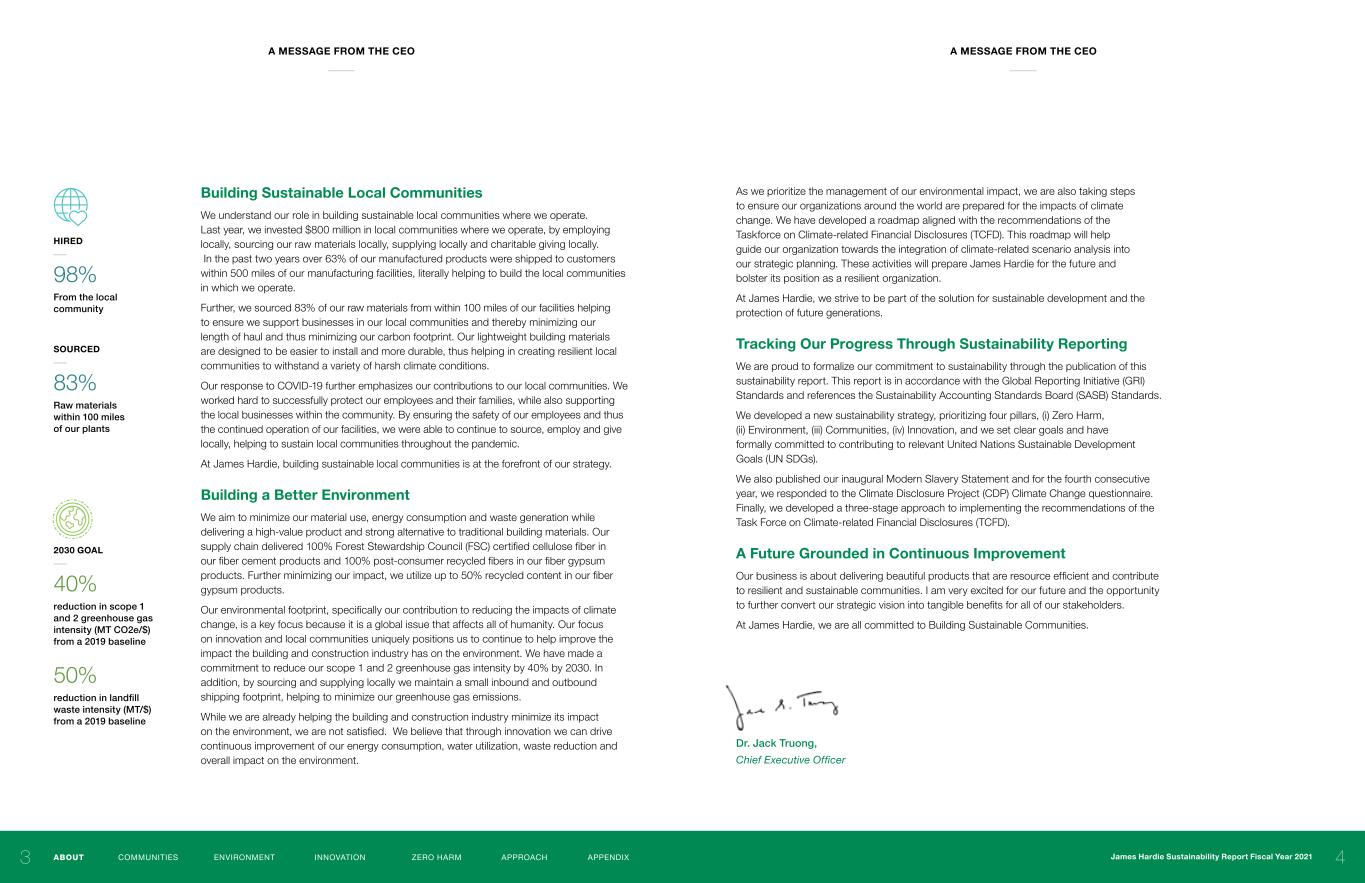

2030 GOAL 40% reduction in scope 1 and 2 greenhouse gas intensity (MT CO2e/$) from a 2019 baseline 50% reduction in landfill waste intensity (MT/$) from a 2019 baseline HIRED 98% From the local community SOURCED 83% Raw materials within 100 miles of our plants Building Sustainable Local Communities We understand our role in building sustainable local communities where we operate. Last year, we invested $800 million in local communities where we operate, by employing locally, sourcing our raw materials locally, supplying locally and charitable giving locally. In the past two years over 63% of our manufactured products were shipped to customers within 500 miles of our manufacturing facilities, literally helping to build the local communities in which we operate. Further, we sourced 83% of our raw materials from within 100 miles of our facilities helping to ensure we support businesses in our local communities and thereby minimizing our length of haul and thus minimizing our carbon footprint. Our lightweight building materials are designed to be easier to install and more durable, thus helping in creating resilient local communities to withstand a variety of harsh climate conditions. Our response to COVID-19 further emphasizes our contributions to our local communities. We worked hard to successfully protect our employees and their families, while also supporting the local businesses within the community. By ensuring the safety of our employees and thus the continued operation of our facilities, we were able to continue to source, employ and give locally, helping to sustain local communities throughout the pandemic. At James Hardie, building sustainable local communities is at the forefront of our strategy. Building a Better Environment We aim to minimize our material use, energy consumption and waste generation while delivering a high-value product and strong alternative to traditional building materials. Our supply chain delivered 100% Forest Stewardship Council (FSC) certified cellulose fiber in our fiber cement products and 100% post-consumer recycled fibers in our fiber gypsum products. Further minimizing our impact, we utilize up to 50% recycled content in our fiber gypsum products. Our environmental footprint, specifically our contribution to reducing the impacts of climate change, is a key focus because it is a global issue that affects all of humanity. Our focus on innovation and local communities uniquely positions us to continue to help improve the impact the building and construction industry has on the environment. We have made a commitment to reduce our scope 1 and 2 greenhouse gas intensity by 40% by 2030. In addition, by sourcing and supplying locally we maintain a small inbound and outbound shipping footprint, helping to minimize our greenhouse gas emissions. While we are already helping the building and construction industry minimize its impact on the environment, we are not satisfied. We believe that through innovation we can drive continuous improvement of our energy consumption, water utilization, waste reduction and overall impact on the environment. As we prioritize the management of our environmental impact, we are also taking steps to ensure our organizations around the world are prepared for the impacts of climate change. We have developed a roadmap aligned with the recommendations of the Taskforce on Climate-related Financial Disclosures (TCFD). This roadmap will help guide our organization towards the integration of climate-related scenario analysis into our strategic planning. These activities will prepare James Hardie for the future and bolster its position as a resilient organization. At James Hardie, we strive to be part of the solution for sustainable development and the protection of future generations. Tracking Our Progress Through Sustainability Reporting We are proud to formalize our commitment to sustainability through the publication of this sustainability report. This report is in accordance with the Global Reporting Initiative (GRI) Standards and references the Sustainability Accounting Standards Board (SASB) Standards. We developed a new sustainability strategy, prioritizing four pillars, (i) Zero Harm, (ii) Environment, (iii) Communities, (iv) Innovation, and we set clear goals and have formally committed to contributing to relevant United Nations Sustainable Development Goals (UN SDGs). We also published our inaugural Modern Slavery Statement and for the fourth consecutive year, we responded to the Climate Disclosure Project (CDP) Climate Change questionnaire. Finally, we developed a three-stage approach to implementing the recommendations of the Task Force on Climate-related Financial Disclosures (TCFD). A Future Grounded in Continuous Improvement Our business is about delivering beautiful products that are resource efficient and contribute to resilient and sustainable communities. I am very excited for our future and the opportunity to further convert our strategic vision into tangible benefits for all of our stakeholders. At James Hardie, we are all committed to Building Sustainable Communities. Dr. Jack Truong, Chief Executive Officer 43 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX A MESSAGE FROM THE CEOA MESSAGE FROM THE CEO

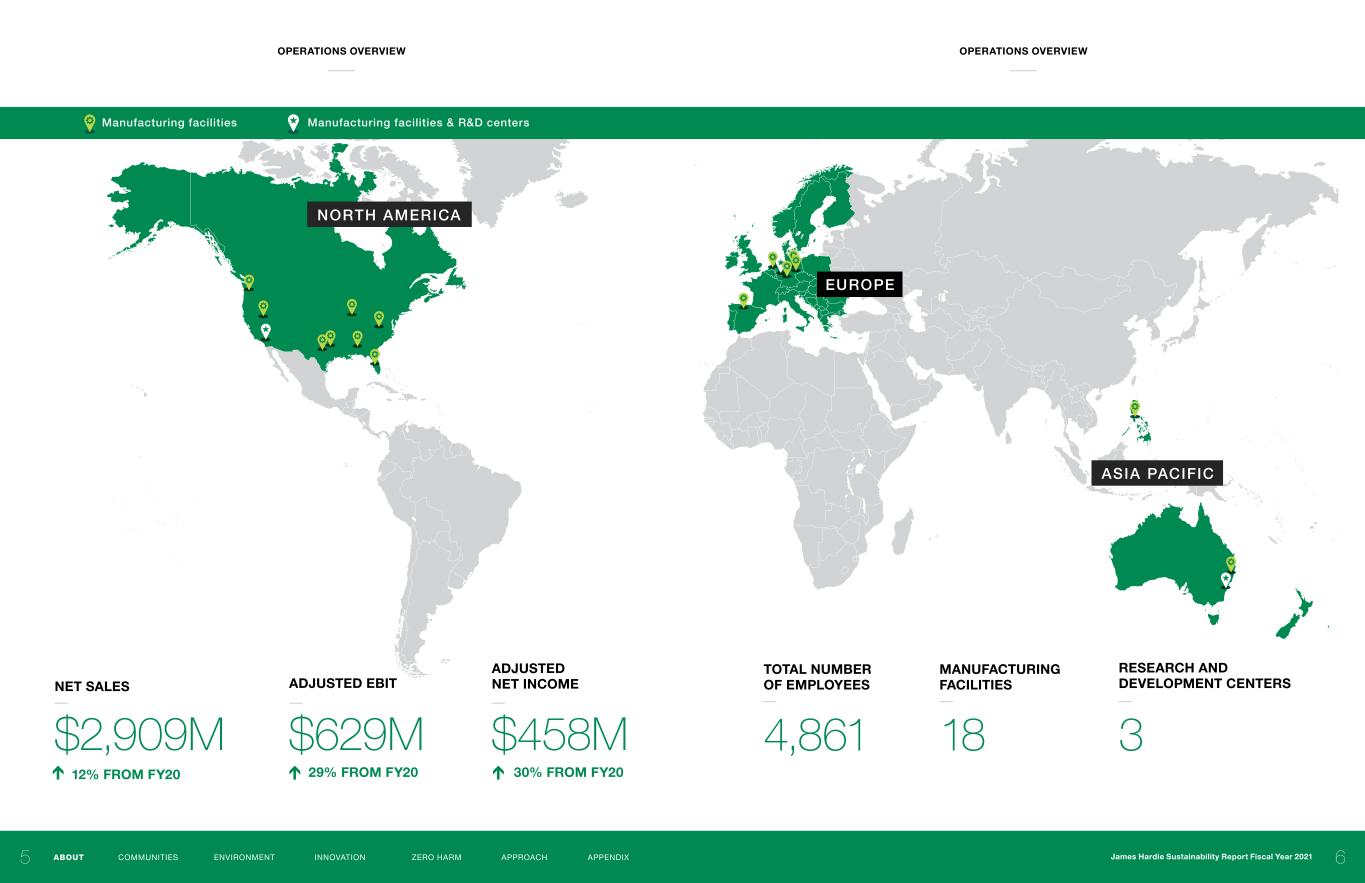

ASIA PACIFIC EUROPE NORTH AMERICA ASIA PACIFIC EUROPE NORTH AMERICA Manufacturing facilities Manufacturing facilities & R&D centers $458M$629M 30% FROM FY20 ADJUSTED NET INCOME 12% FROM FY20 ADJUSTED EBIT 29% FROM FY20 $2,909M NET SALES 18 MANUFACTURING FACILITIES 3 RESEARCH AND DEVELOPMENT CENTERS 4,861 TOTAL NUMBER OF EMPLOYEES 65 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX OPERATIONS OVERVIEW OPERATIONS OVERVIEW

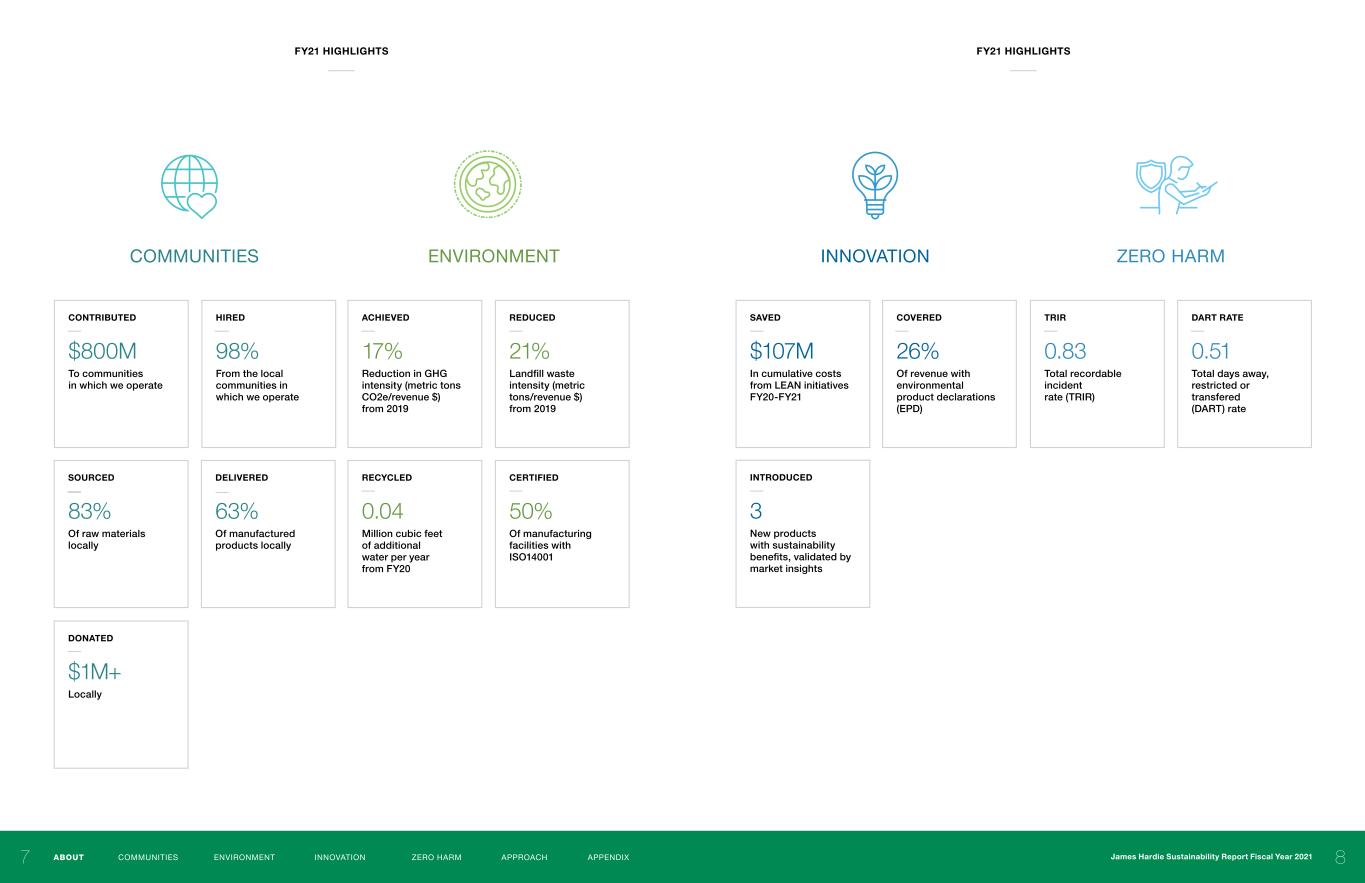

ZERO HARMENVIRONMENT INNOVATION DART RATE 0.51 Total days away, restricted or transfered (DART) rate TRIR 0.83 Total recordable incident rate (TRIR) INTRODUCED 3 New products with sustainability benefits, validated by market insights DELIVERED 63% Of manufactured products locally REDUCED 21% Landfill waste intensity (metric tons/revenue $) from 2019 RECYCLED 0.04 Million cubic feet of additional water per year from FY20 CERTIFIED 50% Of manufacturing facilities with ISO14001 ACHIEVED 17% Reduction in GHG intensity (metric tons CO2e/revenue $) from 2019 CONTRIBUTED $800M To communities in which we operate HIRED 98% From the local communities in which we operate SOURCED 83% Of raw materials locally DONATED $1M+ Locally COVERED 26% Of revenue with environmental product declarations (EPD) SAVED $107M In cumulative costs from LEAN initiatives FY20-FY21 COMMUNITIES 87 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX FY21 HIGHLIGHTS FY21 HIGHLIGHTS

Our global strategy for value creation and sustainable operational performance BUILDING SUSTAINABLE COMMUNITIES Our pillarsJames Hardie is committed to improving its sustainability performance and proactively and carefully managing its social and environmental impact. Our sustainability strategy, which was formalized in FY21, is integrated with our global strategy for value creation and operational performance. It focuses on four key pillars of Communities, Environment, Innovation and Zero Harm. We carefully manage the impact under our direct operational control through integrated operating and management systems such as the Hardie Manufacturing Operating System (HMOS) based on LEAN methodology. We also proactively seek out ways to influence the sustainability impacts in our value chain as they relate to our operations. ENVIRONMENT We seek to minimize our impact on the environment, and we prioritize the management of water, waste, energy and emissions. COMMUNITIES With a global mindset, we carefully manage our business impact by employing, sourcing, delivering and giving locally. ZERO HARM With our Zero Harm culture, we seek to ensure the safety of our products, employees, partners, customers and communities. INNOVATION We are committed to transforming new technologies into high-quality and sustainable products, solutions, and building practices. “ James Hardie is a company that’s not content to remain static. Instead, it’s an organization that’s constantly looking for ways to improve performance and deliver better products.” Jason Miele, Chief Financial Officer AT-A-GLANCE 109 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

Our commitment We carefully manage our impacts with a global mindset while creating value in and for our communities. Our goal Create a positive impact in the communities in which we operate. Our approach We employ, source, deliver and give locally. FY21 performance COMMUNITIES We create value in and for our communities $800M 98% 83% $1M+ 63% contributed to local economies hired from the local communities of raw materials sourced locally donated locally of manufactured products delivered locally AT-A-GLANCE 1211 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

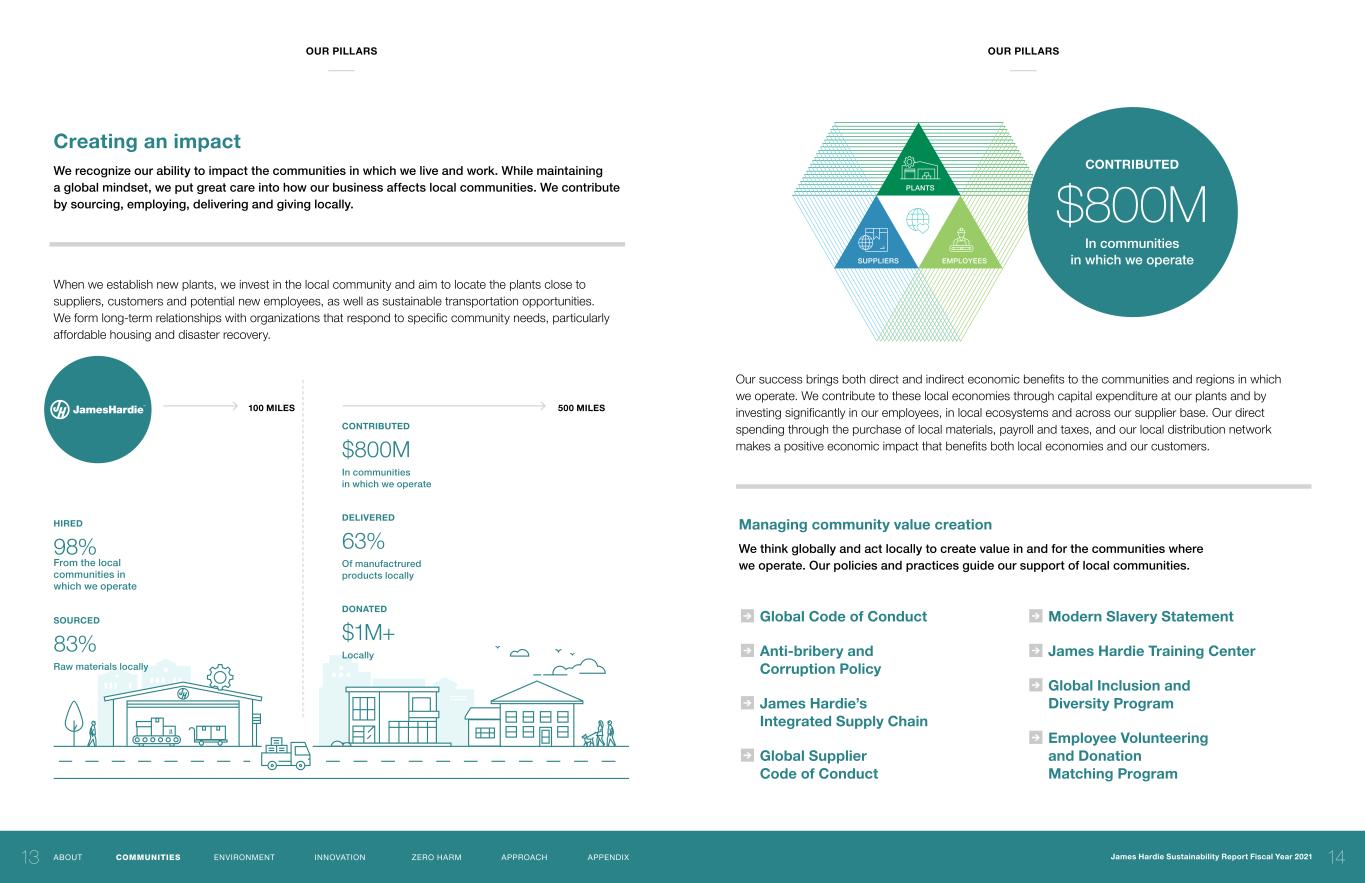

EMPLOYEESSUPPLIERS PLANTS CONTRIBUTED $800M In communities in which we operate Managing community value creation We think globally and act locally to create value in and for the communities where we operate. Our policies and practices guide our support of local communities. Global Code of Conduct Anti-bribery and Corruption Policy James Hardie’s Integrated Supply Chain Global Supplier Code of Conduct Modern Slavery Statement James Hardie Training Center Global Inclusion and Diversity Program Employee Volunteering and Donation Matching Program Creating an impact We recognize our ability to impact the communities in which we live and work. While maintaining a global mindset, we put great care into how our business affects local communities. We contribute by sourcing, employing, delivering and giving locally. When we establish new plants, we invest in the local community and aim to locate the plants close to suppliers, customers and potential new employees, as well as sustainable transportation opportunities. We form long-term relationships with organizations that respond to specific community needs, particularly affordable housing and disaster recovery. CONTRIBUTED $800M In communities in which we operate DELIVERED 63% Of manufactrured products locally DONATED $1M+ Locally 100 MILES 500 MILES HIRED 98% From the local communities in which we operate SOURCED 83% Raw materials locally Our success brings both direct and indirect economic benefits to the communities and regions in which we operate. We contribute to these local economies through capital expenditure at our plants and by investing significantly in our employees, in local ecosystems and across our supplier base. Our direct spending through the purchase of local materials, payroll and taxes, and our local distribution network makes a positive economic impact that benefits both local economies and our customers. OUR PILLARS OUR PILLARS 1413 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

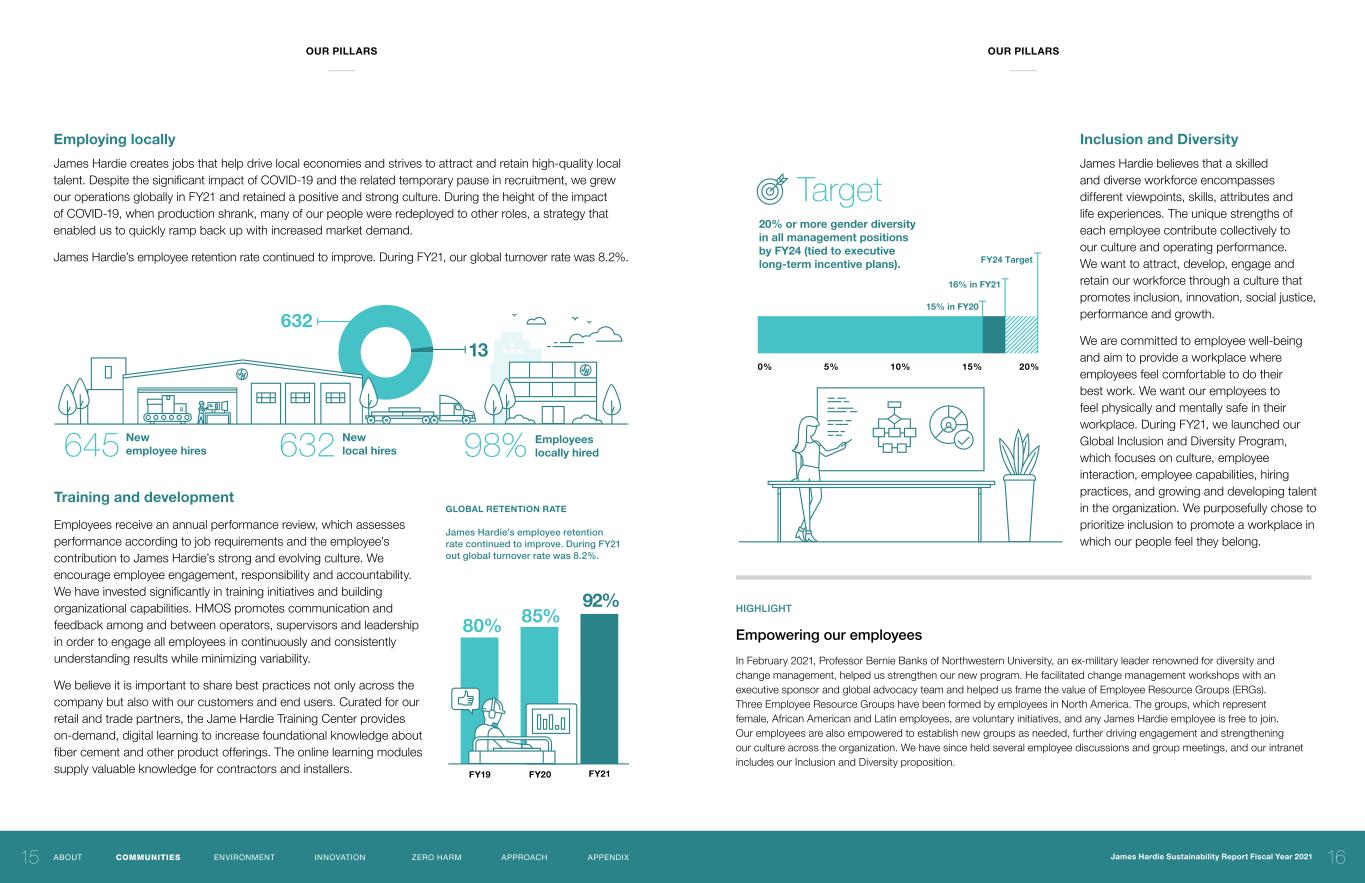

632 13 98% Employees locally hired New local hires New employee hires 632645 Target 20% or more gender diversity in all management positions by FY24 (tied to executive long-term incentive plans). 15% in FY20 16% in FY21 FY24 Target 0% 5% 10% 15% 20% 20 or ore gender diversity in a l anage ent positions by FY24 (tied to executive long-ter incentive plans). 15 in FY20 16 in FY21 FY24 Target 0 5 10 15 20 92% 85%80% FY19 FY20 FY21 Inclusion and Diversity James Hardie believes that a skilled and diverse workforce encompasses different viewpoints, skills, attributes and life experiences. The unique strengths of each employee contribute collectively to our culture and operating performance. We want to attract, develop, engage and retain our workforce through a culture that promotes inclusion, innovation, social justice, performance and growth. We are committed to employee well-being and aim to provide a workplace where employees feel comfortable to do their best work. We want our employees to feel physically and mentally safe in their workplace. During FY21, we launched our Global Inclusion and Diversity Program, which focuses on culture, employee interaction, employee capabilities, hiring practices, and growing and developing talent in the organization. We purposefully chose to prioritize inclusion to promote a workplace in which our people feel they belong. HIGHLIGHT Empowering our employees In February 2021, Professor Bernie Banks of Northwestern University, an ex-military leader renowned for diversity and change management, helped us strengthen our new program. He facilitated change management workshops with an executive sponsor and global advocacy team and helped us frame the value of Employee Resource Groups (ERGs). Three Employee Resource Groups have been formed by employees in North America. The groups, which represent female, African American and Latin employees, are voluntary initiatives, and any James Hardie employee is free to join. Our employees are also empowered to establish new groups as needed, further driving engagement and strengthening our culture across the organization. We have since held several employee discussions and group meetings, and our intranet includes our Inclusion and Diversity proposition. Training and development Employees receive an annual performance review, which assesses performance according to job requirements and the employee’s contribution to James Hardie’s strong and evolving culture. We encourage employee engagement, responsibility and accountability. We have invested significantly in training initiatives and building organizational capabilities. HMOS promotes communication and feedback among and between operators, supervisors and leadership in order to engage all employees in continuously and consistently understanding results while minimizing variability. We believe it is important to share best practices not only across the company but also with our customers and end users. Curated for our retail and trade partners, the Jame Hardie Training Center provides on-demand, digital learning to increase foundational knowledge about fiber cement and other product offerings. The online learning modules supply valuable knowledge for contractors and installers. Employing locally James Hardie creates jobs that help drive local economies and strives to attract and retain high-quality local talent. Despite the significant impact of COVID-19 and the related temporary pause in recruitment, we grew our operations globally in FY21 and retained a positive and strong culture. During the height of the impact of COVID-19, when production shrank, many of our people were redeployed to other roles, a strategy that enabled us to quickly ramp back up with increased market demand. James Hardie’s employee retention rate continued to improve. During FY21, our global turnover rate was 8.2%. GLOBAL RETENTION RATE James Hardie’s employee retention rate continued to improve. During FY21 out global turnover rate was 8.2%. OUR PILLARS OUR PILLARS 1615 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

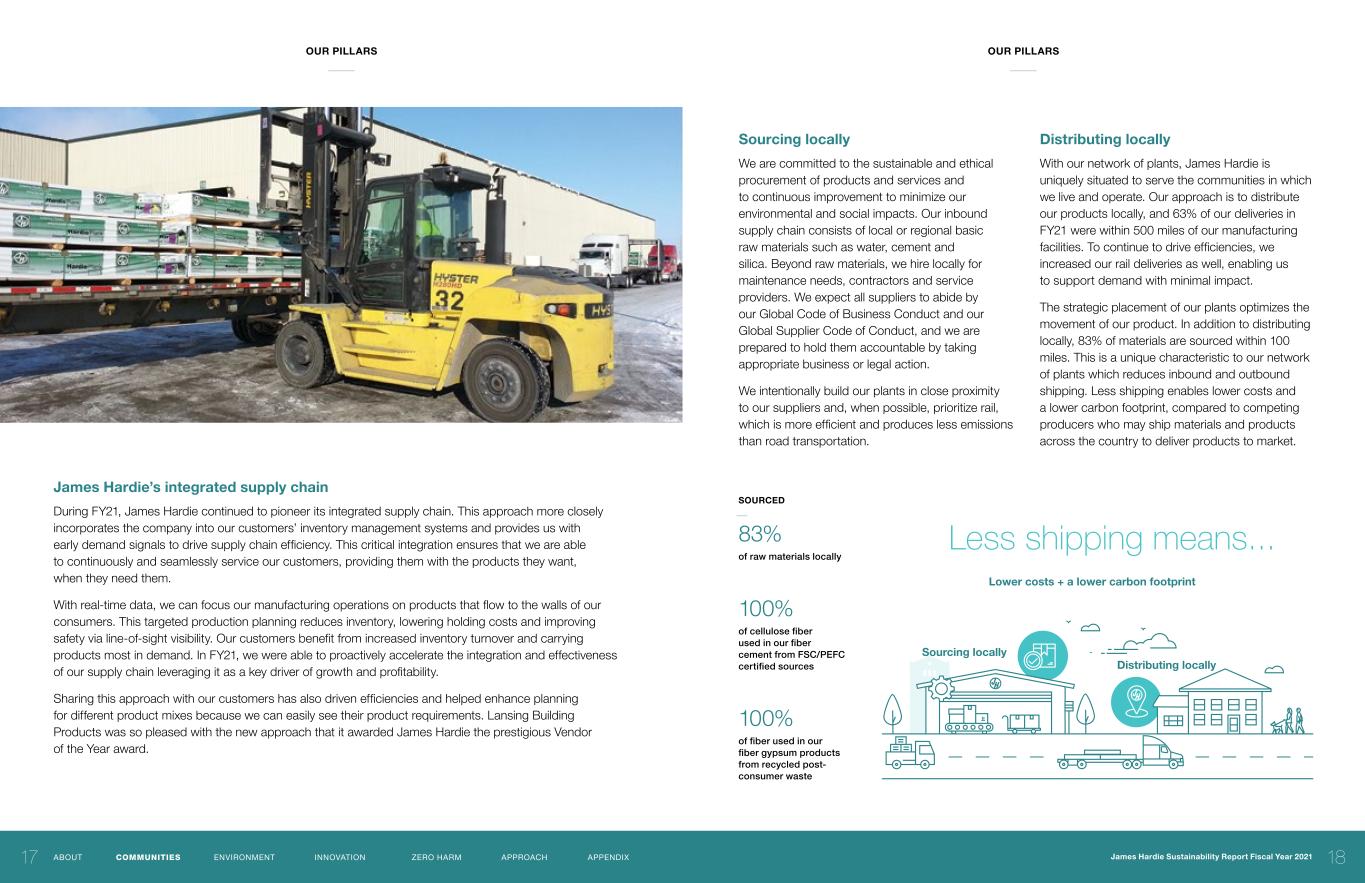

Sourcing locally Distributing locally Less shipping means... Lower costs + a lower carbon footprint Distributing locally With our network of plants, James Hardie is uniquely situated to serve the communities in which we live and operate. Our approach is to distribute our products locally, and 63% of our deliveries in FY21 were within 500 miles of our manufacturing facilities. To continue to drive efficiencies, we increased our rail deliveries as well, enabling us to support demand with minimal impact. The strategic placement of our plants optimizes the movement of our product. In addition to distributing locally, 83% of materials are sourced within 100 miles. This is a unique characteristic to our network of plants which reduces inbound and outbound shipping. Less shipping enables lower costs and a lower carbon footprint, compared to competing producers who may ship materials and products across the country to deliver products to market. James Hardie’s integrated supply chain During FY21, James Hardie continued to pioneer its integrated supply chain. This approach more closely incorporates the company into our customers’ inventory management systems and provides us with early demand signals to drive supply chain efficiency. This critical integration ensures that we are able to continuously and seamlessly service our customers, providing them with the products they want, when they need them. With real-time data, we can focus our manufacturing operations on products that flow to the walls of our consumers. This targeted production planning reduces inventory, lowering holding costs and improving safety via line-of-sight visibility. Our customers benefit from increased inventory turnover and carrying products most in demand. In FY21, we were able to proactively accelerate the integration and effectiveness of our supply chain leveraging it as a key driver of growth and profitability. Sharing this approach with our customers has also driven efficiencies and helped enhance planning for different product mixes because we can easily see their product requirements. Lansing Building Products was so pleased with the new approach that it awarded James Hardie the prestigious Vendor of the Year award. SOURCED 83% of raw materials locally 100% of cellulose fiber used in our fiber cement from FSC/PEFC certified sources 100% of fiber used in our fiber gypsum products from recycled post- consumer waste Sourcing locally We are committed to the sustainable and ethical procurement of products and services and to continuous improvement to minimize our environmental and social impacts. Our inbound supply chain consists of local or regional basic raw materials such as water, cement and silica. Beyond raw materials, we hire locally for maintenance needs, contractors and service providers. We expect all suppliers to abide by our Global Code of Business Conduct and our Global Supplier Code of Conduct, and we are prepared to hold them accountable by taking appropriate business or legal action. We intentionally build our plants in close proximity to our suppliers and, when possible, prioritize rail, which is more efficient and produces less emissions than road transportation. OUR PILLARS OUR PILLARS 1817 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

During FY21, we donated more than US $1 million in products and company donations to organizations including but not limited to: › American Civil Liberties Union › American Institute For Cancer › Animal Rescue League Of Iowa › ASCPA › Big Shoulders Fund › Cancer Research Institute › Charity Water › Chicago Help Initiative › Christopher House › Direct Relief › Drake University › Entertainment Industry Foundation › Evans Scholars Foundation › Feed The Hungry › Feeding America › Feeding Texas › GiveWell › Greater Chicago Food › Hope Charities USA › Jewish United Fund › Laura’s House › Leukemia & Lymphoma Society › Los Alamitos Education Foundation › Lurie Children’s Foundation › Madonna Learning Center › Magnolia Foundation › Metro Maryland Youth For Christ › Mobile Loaves And Fishes › Mutual Ground › My Block My Hood My City › NAACP › Over The Rainbow Association › Renaissance Institute Of Music › Rescue Missions Ministries, In › River Valley Juniors › Rocky Mountain Elk Foundation › Shriver Center On Poverty Law › St Jude Children’s Research › St. Ignatius Loyola Academy › Surge For Water › The Michael J Fox Foundation › University Of Notre Dame › University Of Wisconsin Foundation › Wilmette Community Nursery School Sami Rahman, VP Product Management, is a Board member of OTR, a charity dedicated to increasing the quality of life for individuals with physical disabilities through the creation of affordable, accessible, barrier-free housing solutions and person-centered services that encourage independent living. Jeff Kemerley, Sr. Director, Interiors, is a Board member at Christopher House, a charity that provides education and immersive family support services to at-risk children and their families in the Uptown and West Side areas of Chicago Amplifying the voices of our employees “ Many young people in our community simply don’t have the developmental support they need … Christopher House helps close this gap.” “ Access to equitable housing is something we care about deeply and it is great to support an organization like OTR right in our backyard.” HIGHLIGHT James Hardie Inclusion and Diversity Scholarship In May 2021, James Hardie named six students in the U.S. the recipients of the James Hardie Inclusion and Diversity Scholarship. This $5,000 annual scholarship, up to $20,000 per student, is being piloted by James Hardie plants across the country. As part of our commitment to being a globally diverse workplace that reflects the communities in which we operate and serve, we are excited to offer this new scholarship opportunity. We want to help ease the financial burden on students, and their families, who wish to continue their education at the college level. Supporting locally We typically operate in smaller towns and strive to positively impact the people and families in the communities in which we operate and where our products are used. Our products help build and protect homes for families around the world, providing us with a direct path for working with nonprofits in need of building materials. As a result, we have established long-term relationships with several partners that respond to specific needs related to housing and community resilience, with a focus on affordable housing, home building and repair, and disaster recovery. To this end, several of our senior leaders sit on boards or hold volunteer positions at nonprofit organizations. In addition, James Hardie’s charitable program supports the company’s vision and belief that the well-being of communities has a direct impact on the success of the business and employees. We believe in amplifying the voice of our employees and empowering them to offer their support locally. Our program consists of three platforms: › Charitable matching to honor the diversity of our employees’ giving by supporting a broad spectrum of eligible organizations and institutions that serve our communities. › Charitable volunteer hours to support individual employee volunteer efforts by offering a company charitable contribution gift to qualifying charities where an employee has volunteered their time. › Company donations managed by office and plant locations where employees are encouraged to support local charitable efforts that align with James Hardie’s vision of meeting basic needs and enhancing community vitality. OUR PILLARS OUR PILLARS 2019 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

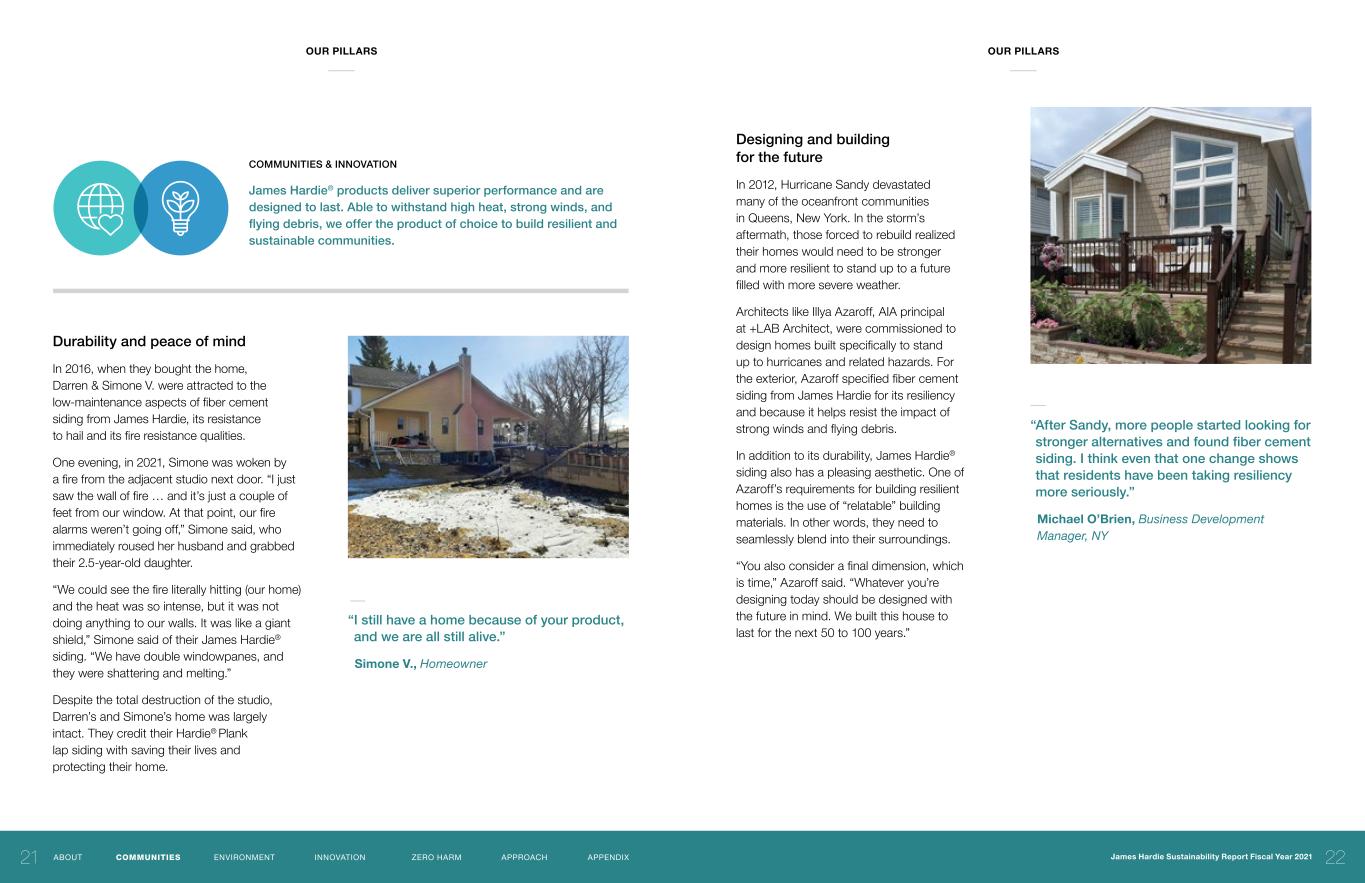

Durability and peace of mind In 2016, when they bought the home, Darren & Simone V. were attracted to the low-maintenance aspects of fiber cement siding from James Hardie, its resistance to hail and its fire resistance qualities. One evening, in 2021, Simone was woken by a fire from the adjacent studio next door. “I just saw the wall of fire … and it’s just a couple of feet from our window. At that point, our fire alarms weren’t going off,” Simone said, who immediately roused her husband and grabbed their 2.5-year-old daughter. “We could see the fire literally hitting (our home) and the heat was so intense, but it was not doing anything to our walls. It was like a giant shield,” Simone said of their James Hardie® siding. “We have double windowpanes, and they were shattering and melting.” Despite the total destruction of the studio, Darren’s and Simone’s home was largely intact. They credit their Hardie® Plank lap siding with saving their lives and protecting their home. COMMUNITIES & INNOVATION James Hardie® products deliver superior performance and are designed to last. Able to withstand high heat, strong winds, and flying debris, we offer the product of choice to build resilient and sustainable communities. “ I still have a home because of your product, and we are all still alive.” Simone V., Homeowner “ After Sandy, more people started looking for stronger alternatives and found fiber cement siding. I think even that one change shows that residents have been taking resiliency more seriously.” Michael O’Brien, Business Development Manager, NY Designing and building for the future In 2012, Hurricane Sandy devastated many of the oceanfront communities in Queens, New York. In the storm’s aftermath, those forced to rebuild realized their homes would need to be stronger and more resilient to stand up to a future filled with more severe weather. Architects like Illya Azaroff, AIA principal at +LAB Architect, were commissioned to design homes built specifically to stand up to hurricanes and related hazards. For the exterior, Azaroff specified fiber cement siding from James Hardie for its resiliency and because it helps resist the impact of strong winds and flying debris. In addition to its durability, James Hardie® siding also has a pleasing aesthetic. One of Azaroff’s requirements for building resilient homes is the use of “relatable” building materials. In other words, they need to seamlessly blend into their surroundings. “You also consider a final dimension, which is time,” Azaroff said. “Whatever you’re designing today should be designed with the future in mind. We built this house to last for the next 50 to 100 years.” OUR PILLARS OUR PILLARS 2221 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

“ James Hardie was the main factor that kept the doors open.” Derek George, West End Grill West End Grill Holly & Derek George are a married couple that own West End Grill in Cleburne, TX. Truly a “Mom and Pop” operation. They have been serving James Hardie at the Cleburne plant since the early 1990’s, Through the pandemic, James Hardie’s daily lunch program was their main source of business and the only company they catered. In 2019, Holly & Derek had 31 employees; today, they have 11. Fortunately, their business has grown back to “pre-COVID-19 levels” and they are working towards bringing back staff. We truly thank Holly & Derek for their dedication to our James Hardie employees throughout the years. We’re glad to have had the opportunity to support them throughout the pandemic and look forward to many great meals ahead! COMMUNITIES & ZERO HARM Throughout the pandemic, James Hardie introduced an onsite daily lunch program throughout North America. The program is designed to offer free onsite lunch to all employees, reducing their risk of exposure to COVID-19, minimizing opportunities for community spread, and patronizing local businesses to support them through difficult times. “ When James Hardie chose our business to partner with, we were blessed. We were not only able to save our business but also keep our family employed.” Eddie, Tacos El Guero Tacos El Guero Eddie (not pictured) started his business, Tacos El Guero, in Fontana, CA after he lost his job several years ago. Eddie operates his business with the help of his family (pictured). When the pandemic started, and full lockdowns were in place, their business began to suffer tremendously. James Hardie’s Briana Gonzalez was a frequent customer of the restaurant and recommended it as part of our free daily lunch program. Throughout the pandemic they became one of the most, if not the most reliable vendor. They accommodated lunch for each shift, whether it was early morning or a very late graveyard delivery. They delivered to different locations of our facility when we needed to take extra safety measures to limit contact. We truly want to thank Eddie and his family for their dedication to the James Hardie Fontana facility throughout the pandemic and we are happy to continue our partnership. OUR PILLARS OUR PILLARS 2423 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

We are dedicated to environmental excellence ENVIRONMENT Our commitment To be responsible and accountable for our impact on the environment and prioritize the management of waste, water, energy and emissions. Our goal 40% reduction of Scope 1 and Scope 2 greenhouse gas (GHG) intensity by 2030 from a 2019 baseline 50% reduction in landfill waste intensity by 2030 from a 2019 baseline Our approach Renewable sources of energy LEAN manufacturing Recycling FY21 performance 17% 21% reduction in GHG intensity from 2019 reduction in landfill waste intensity from 2019 AT-A-GLANCE 2625 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

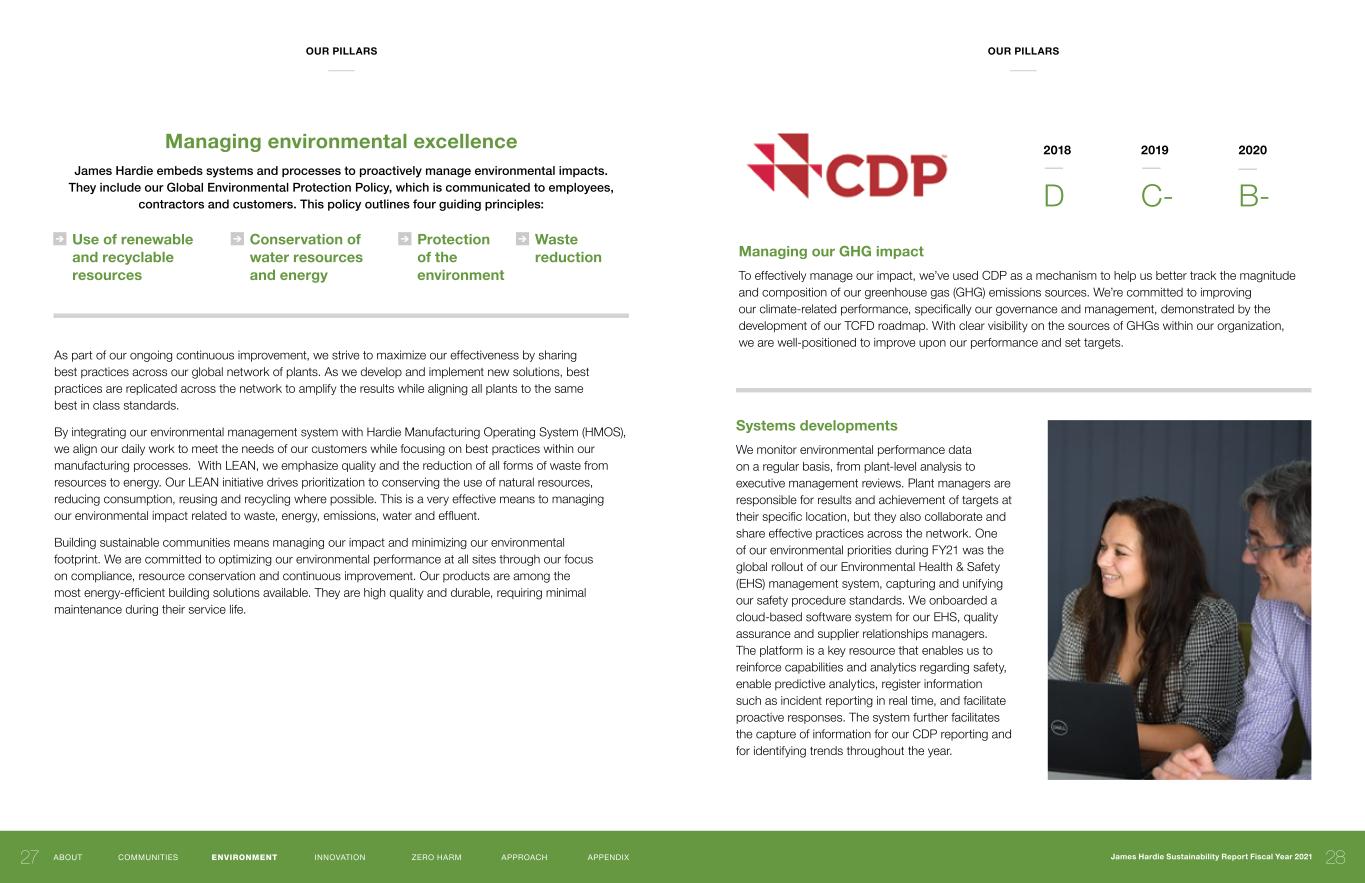

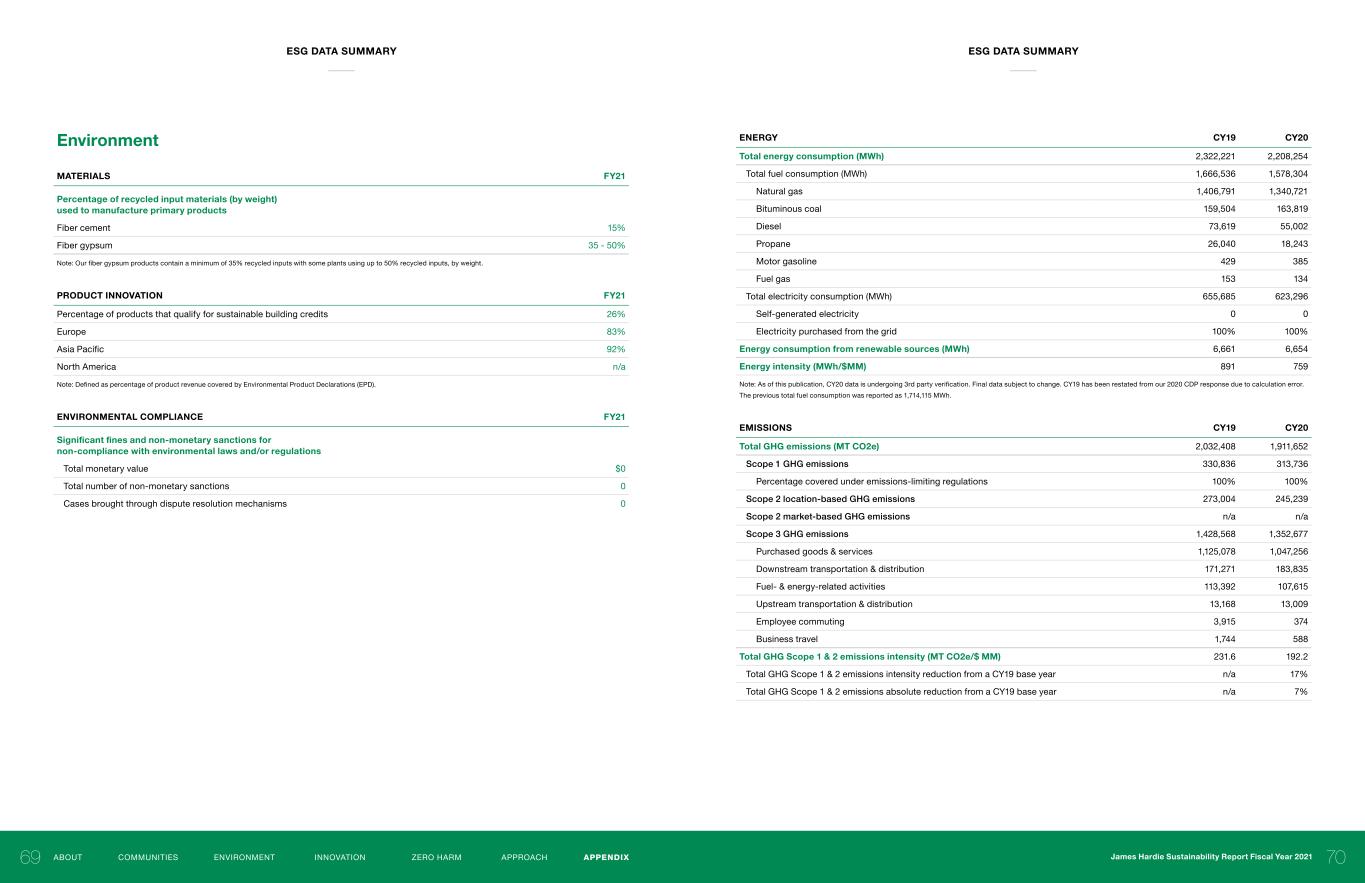

Managing environmental excellence James Hardie embeds systems and processes to proactively manage environmental impacts. They include our Global Environmental Protection Policy, which is communicated to employees, contractors and customers. This policy outlines four guiding principles: Use of renewable and recyclable resources As part of our ongoing continuous improvement, we strive to maximize our effectiveness by sharing best practices across our global network of plants. As we develop and implement new solutions, best practices are replicated across the network to amplify the results while aligning all plants to the same best in class standards. By integrating our environmental management system with Hardie Manufacturing Operating System (HMOS), we align our daily work to meet the needs of our customers while focusing on best practices within our manufacturing processes. With LEAN, we emphasize quality and the reduction of all forms of waste from resources to energy. Our LEAN initiative drives prioritization to conserving the use of natural resources, reducing consumption, reusing and recycling where possible. This is a very effective means to managing our environmental impact related to waste, energy, emissions, water and effluent. Building sustainable communities means managing our impact and minimizing our environmental footprint. We are committed to optimizing our environmental performance at all sites through our focus on compliance, resource conservation and continuous improvement. Our products are among the most energy-efficient building solutions available. They are high quality and durable, requiring minimal maintenance during their service life. Systems developments We monitor environmental performance data on a regular basis, from plant-level analysis to executive management reviews. Plant managers are responsible for results and achievement of targets at their specific location, but they also collaborate and share effective practices across the network. One of our environmental priorities during FY21 was the global rollout of our Environmental Health & Safety (EHS) management system, capturing and unifying our safety procedure standards. We onboarded a cloud-based software system for our EHS, quality assurance and supplier relationships managers. The platform is a key resource that enables us to reinforce capabilities and analytics regarding safety, enable predictive analytics, register information such as incident reporting in real time, and facilitate proactive responses. The system further facilitates the capture of information for our CDP reporting and for identifying trends throughout the year. Managing our GHG impact To effectively manage our impact, we’ve used CDP as a mechanism to help us better track the magnitude and composition of our greenhouse gas (GHG) emissions sources. We’re committed to improving our climate-related performance, specifically our governance and management, demonstrated by the development of our TCFD roadmap. With clear visibility on the sources of GHGs within our organization, we are well-positioned to improve upon our performance and set targets. 2018 D 2020 B- 2019 C- Conservation of water resources and energy Protection of the environment Waste reduction 2827 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX OUR PILLARS OUR PILLARS

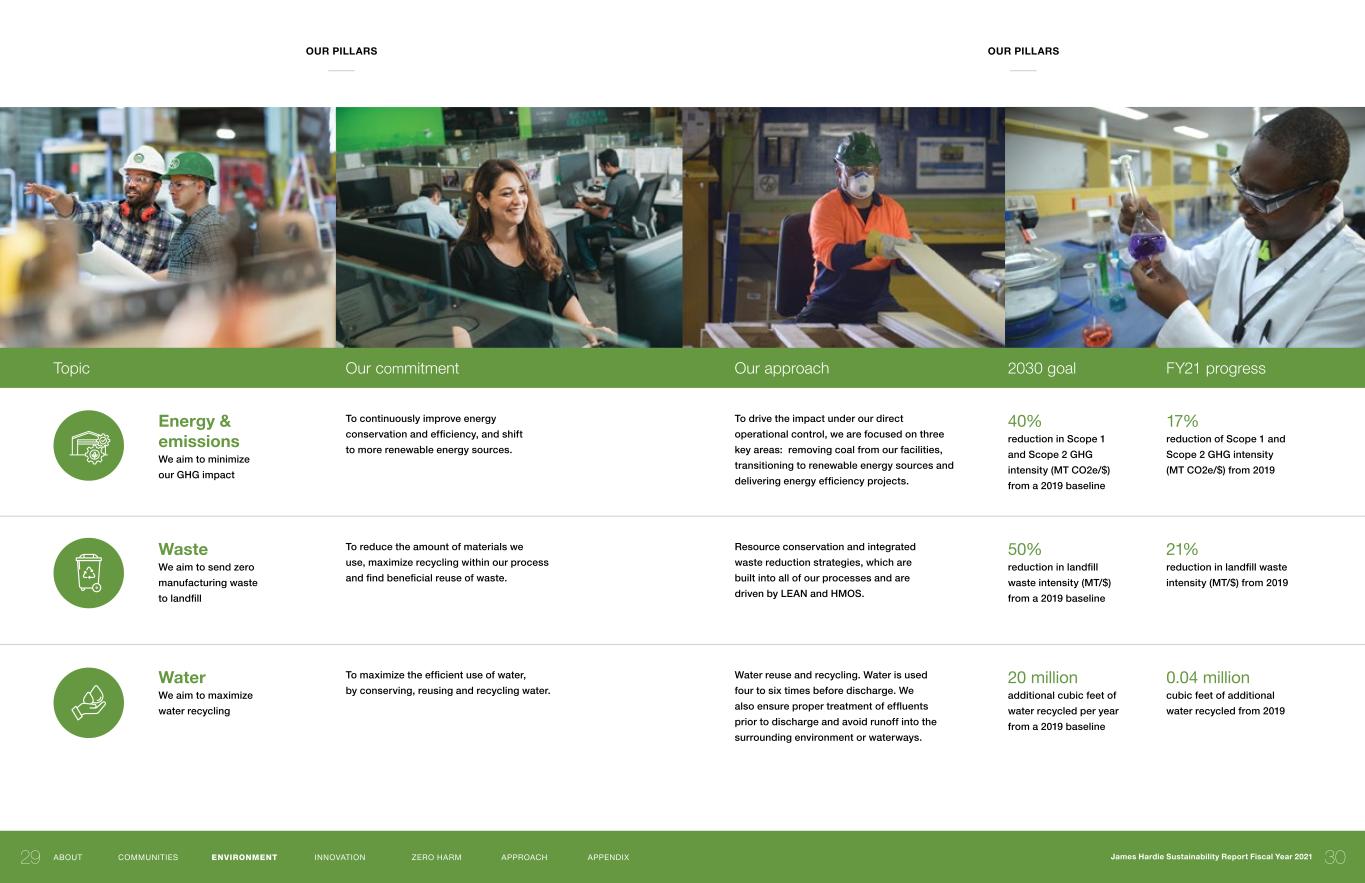

Topic Our commitment Our approach 2030 goal FY21 progress Energy & emissions We aim to minimize our GHG impact To continuously improve energy conservation and efficiency, and shift to more renewable energy sources. To drive the impact under our direct operational control, we are focused on three key areas: removing coal from our facilities, transitioning to renewable energy sources and delivering energy efficiency projects. 40% reduction in Scope 1 and Scope 2 GHG intensity (MT CO2e/$) from a 2019 baseline 17% reduction of Scope 1 and Scope 2 GHG intensity (MT CO2e/$) from 2019 Waste We aim to send zero manufacturing waste to landfill To reduce the amount of materials we use, maximize recycling within our process and find beneficial reuse of waste. Resource conservation and integrated waste reduction strategies, which are built into all of our processes and are driven by LEAN and HMOS. 50% reduction in landfill waste intensity (MT/$) from a 2019 baseline 21% reduction in landfill waste intensity (MT/$) from 2019 Water We aim to maximize water recycling To maximize the efficient use of water, by conserving, reusing and recycling water. Water reuse and recycling. Water is used four to six times before discharge. We also ensure proper treatment of effluents prior to discharge and avoid runoff into the surrounding environment or waterways. 20 million additional cubic feet of water recycled per year from a 2019 baseline 0.04 million cubic feet of additional water recycled from 2019 OUR PILLARS 3029 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX OUR PILLARS

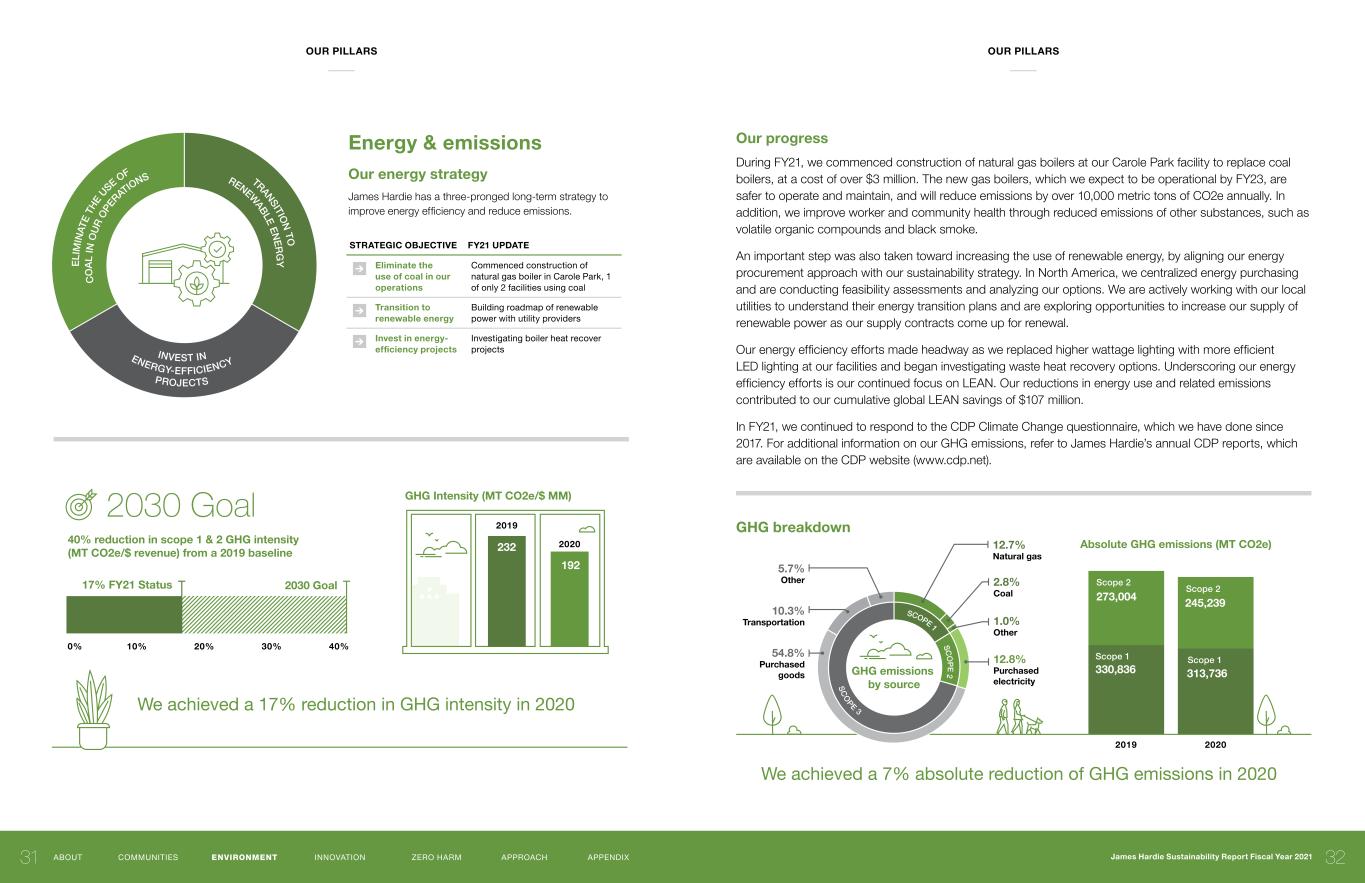

ENERGY-EFFICIENCY INVEST IN PROJECTS TRANSITIO N TO RENEW ABLE EN E R G Y E LI M IN AT E TH E USE O F C O A L IN O U R O PE RATIONS 2030 Goal We achieved a 17% reduction in GHG intensity in 2020 40% reduction in scope 1 & 2 GHG intensity (MT CO2e/$ revenue) from a 2019 baseline GHG Intensity (MT CO2e/$ MM) 17% FY21 Status 2030 Goal 0% 10% 20% 30% 40% 192 232 2019 2020 We achieved a 7% absolute reduction of GHG emissions in 2020 12.7% Natural gas 1.0% Other 2.8% Coal Absolute GHG emissions (MT CO2e) 273,004 330,836 245,239 313,736 2019 2020 GHG emissions by source 5.7% Other 10.3% Transportation 12.8% Purchased electricity 54.8% Purchased goods SCOPE 1 SC O P E 2 S C O PE 3 Scope 1 Scope 1 Scope 2 Scope 2 Our energy strategy James Hardie has a three-pronged long-term strategy to improve energy efficiency and reduce emissions. Energy & emissions STRATEGIC OBJECTIVE FY21 UPDATE Eliminate the use of coal in our operations Commenced construction of natural gas boiler in Carole Park, 1 of only 2 facilities using coal Transition to renewable energy Building roadmap of renewable power with utility providers Invest in energy- efficiency projects Investigating boiler heat recover projects Our progress During FY21, we commenced construction of natural gas boilers at our Carole Park facility to replace coal boilers, at a cost of over $3 million. The new gas boilers, which we expect to be operational by FY23, are safer to operate and maintain, and will reduce emissions by over 10,000 metric tons of CO2e annually. In addition, we improve worker and community health through reduced emissions of other substances, such as volatile organic compounds and black smoke. An important step was also taken toward increasing the use of renewable energy, by aligning our energy procurement approach with our sustainability strategy. In North America, we centralized energy purchasing and are conducting feasibility assessments and analyzing our options. We are actively working with our local utilities to understand their energy transition plans and are exploring opportunities to increase our supply of renewable power as our supply contracts come up for renewal. Our energy efficiency efforts made headway as we replaced higher wattage lighting with more efficient LED lighting at our facilities and began investigating waste heat recovery options. Underscoring our energy efficiency efforts is our continued focus on LEAN. Our reductions in energy use and related emissions contributed to our cumulative global LEAN savings of $107 million. In FY21, we continued to respond to the CDP Climate Change questionnaire, which we have done since 2017. For additional information on our GHG emissions, refer to James Hardie’s annual CDP reports, which are available on the CDP website (www.cdp.net). GHG breakdown OUR PILLARS OUR PILLARS 3231 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

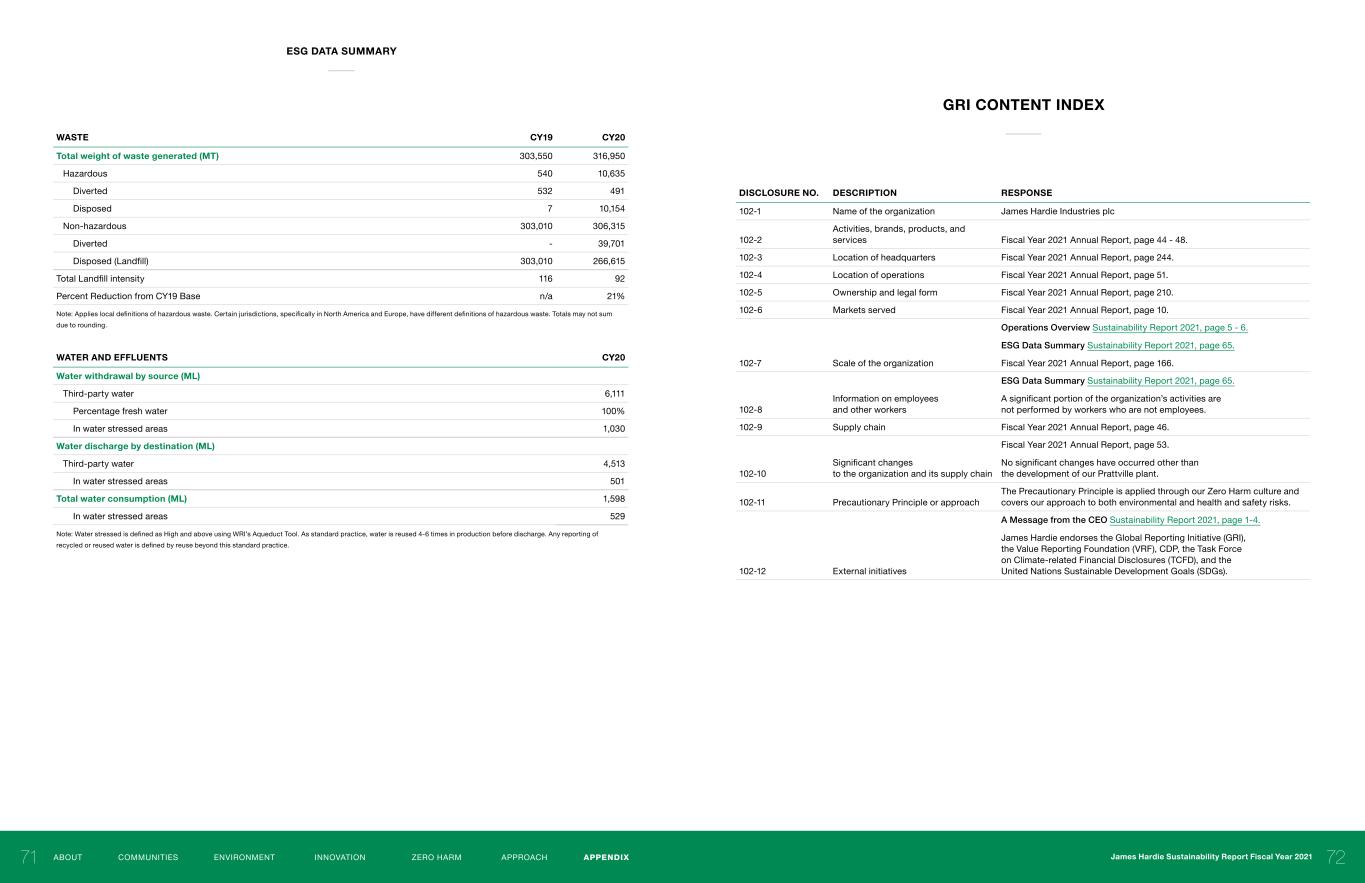

ENABLE BENEFICIAL REUSE MAXIM IZE R EC Y C LIN G G E N E R AT E LE SS W ASTE 2030 Goal We achieved a 21% reduction in landfill waste intensity in 2020 50% reduction in landfill waste intensity (MT/$ revenue) from a 2019 baseline Landfill waste Intensity (MT/$ revenue) 21% FY21 Status 2030 Goal 0% 20%10% 30% 40% 50% 92 116 2019 2020 Our waste strategy We aim to send zero manufacturing waste to landfill through three key strategies: Waste STRATEGIC OBJECTIVE FY21 UPDATE Generate less waste LEAN processes saved us $107M to date In Europe, we continue to send zero product waste to landfill Maximize recycling Up to 15% recycled content in our fiber cement products Up to 50% recycled content in our fiber gypsum products Enable beneficial reuse In APAC, we increased the beneficial reuse of waste In Australia, we increased the diversion of production waste to landfill Beneficial reuse of waste streams Our efforts to send zero waste to landfill, and to find solutions for beneficial reuse of our waste, leverage global best practice sharing. At our fiber cement plants, we recycle waste streams which contribute up to 15% in recycled content to our products. In the Philippines, we strive to send zero waste to landfill and reuse 100% of our fiber cement waste onsite. In Australia, we started by maximizing recycling and have worked to find beneficial reuse for our fiber cement waste. We work with our vendors to recycle the waste back into their process and support municipalities’ beneficial reuse to help build infrastructure, reducing their use of other natural resources. Nearly 100% of our fiber cement is either recycled or put toward beneficial reuse within the communities we operate in Australia. Zero waste production of fiber gypsum In Europe, our fiber gypsum boards are naturally sustainable products that consist of only non-hazardous and natural raw materials, such as gypsum, cellulose, and water. The fiber used in our fiber gypsum products is produced from 100% recycled wastepaper. We also proudly run our European plants as Zero Waste facilities where no landfill waste is generated. All waste materials from our production are constantly collected, processed and, if possible, reused. Any inevitable waste is collected and disposed of in accordance with local and EU guidelines. UP TO 50% recycled content in our fiber gypsum products UP TO 15% recycled content in our fiber cement products OUR PILLARS OUR PILLARS 3433 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

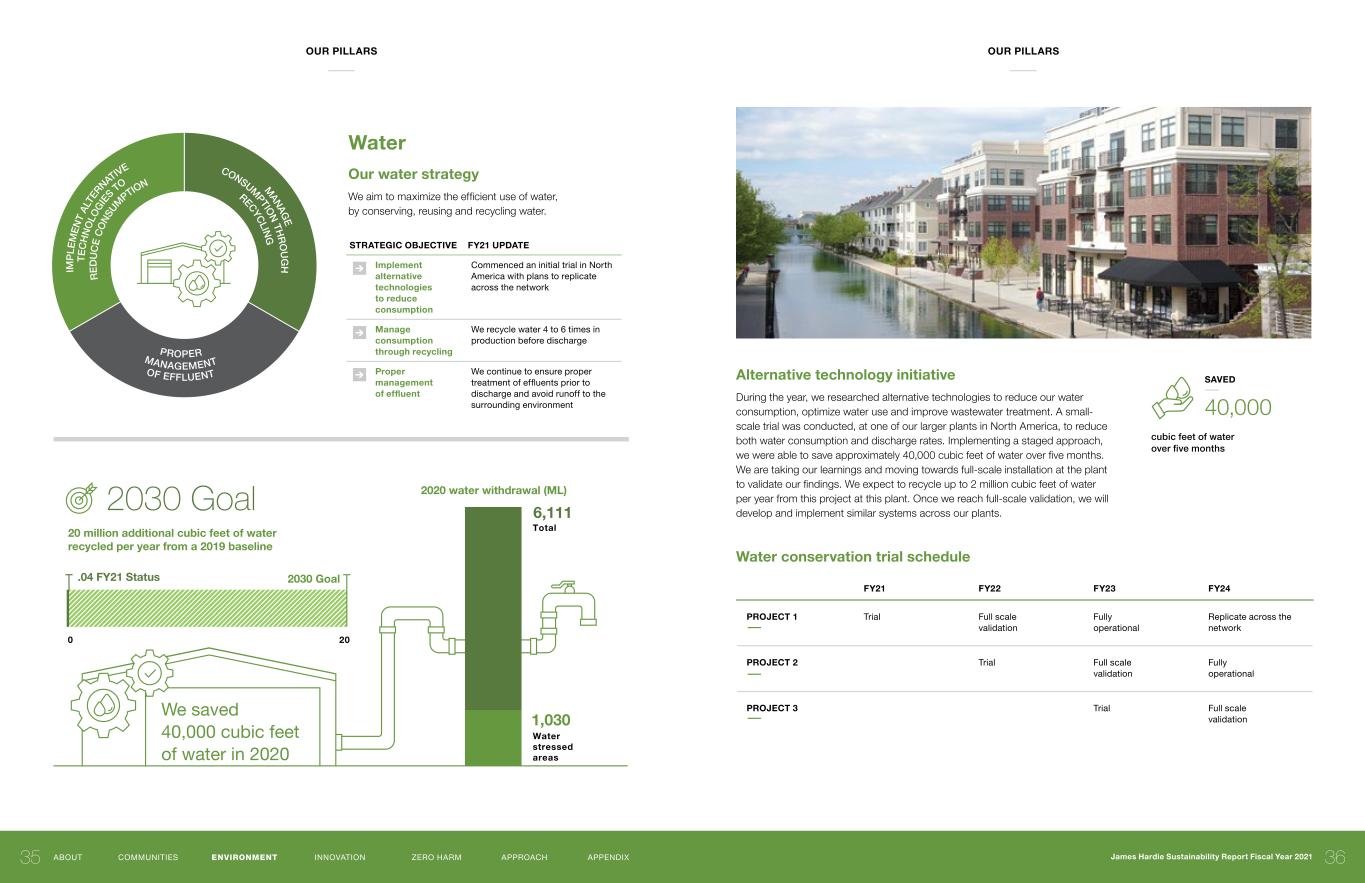

MANAGEMENT PROPER OF EFFLUENT CONSUM PTIO N TH R O U G H RECYC LIN G M AN AG E TE C H N O LO G IE S TO R E D U C E C O N SU M PTION IM P LE M E N T AL TE RNATIVE 2020 water withdrawal (ML)2030 Goal We saved 40,000 cubic feet of water in 2020 20 million additional cubic feet of water recycled per year from a 2019 baseline .04 FY21 Status 2030 Goal 0 20 Water stressed areas Total 6,111 1,030 Our water strategy We aim to maximize the efficient use of water, by conserving, reusing and recycling water. Water STRATEGIC OBJECTIVE FY21 UPDATE Implement alternative technologies to reduce consumption Commenced an initial trial in North America with plans to replicate across the network Manage consumption through recycling We recycle water 4 to 6 times in production before discharge Proper management of effluent We continue to ensure proper treatment of effluents prior to discharge and avoid runoff to the surrounding environment SAVED 40,000 cubic feet of water over five months Alternative technology initiative During the year, we researched alternative technologies to reduce our water consumption, optimize water use and improve wastewater treatment. A small- scale trial was conducted, at one of our larger plants in North America, to reduce both water consumption and discharge rates. Implementing a staged approach, we were able to save approximately 40,000 cubic feet of water over five months. We are taking our learnings and moving towards full-scale installation at the plant to validate our findings. We expect to recycle up to 2 million cubic feet of water per year from this project at this plant. Once we reach full-scale validation, we will develop and implement similar systems across our plants. Water conservation trial schedule FY21 FY22 FY23 FY24 PROJECT 1 Trial Full scale validation Fully operational Replicate across the network PROJECT 2 Trial Full scale validation Fully operational PROJECT 3 Trial Full scale validation OUR PILLARS 3635 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX OUR PILLARS

AT-A-GLANCE INNOVATION Our consumer driven design delivers endless possibilities 326% new products introduced with sustainability benefits of revenue covered with EPDs Our commitment To deliver solutions which improve the lives of the homeowner Our goal 80% of revenue from products with Environmental Product Declarations (EPD) New products to have sustainability benefits Our approach Quality of Life Sustainability Aesthetics Productivity FY21 performance 383837 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

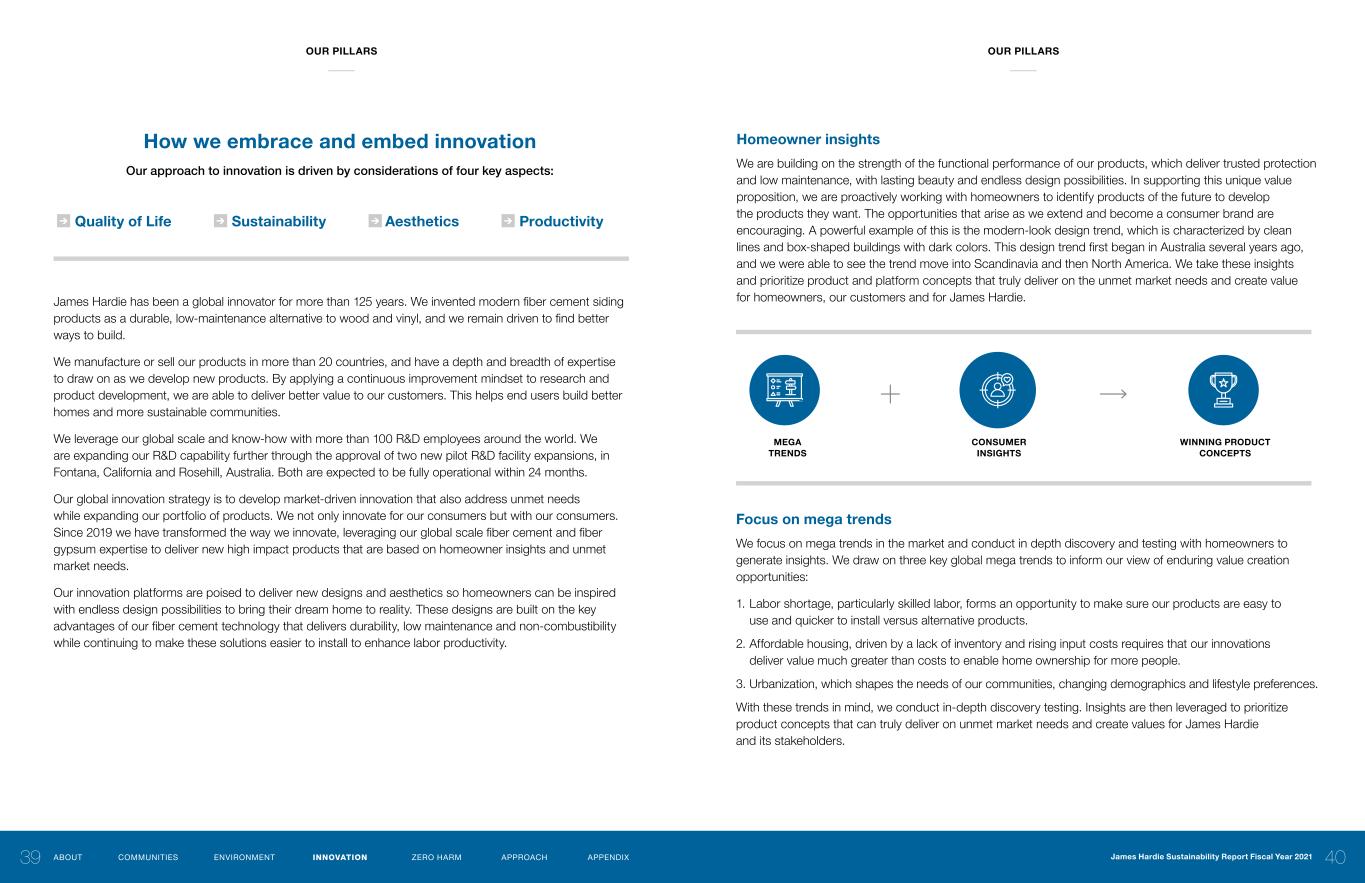

Homeowner insights We are building on the strength of the functional performance of our products, which deliver trusted protection and low maintenance, with lasting beauty and endless design possibilities. In supporting this unique value proposition, we are proactively working with homeowners to identify products of the future to develop the products they want. The opportunities that arise as we extend and become a consumer brand are encouraging. A powerful example of this is the modern-look design trend, which is characterized by clean lines and box-shaped buildings with dark colors. This design trend first began in Australia several years ago, and we were able to see the trend move into Scandinavia and then North America. We take these insights and prioritize product and platform concepts that truly deliver on the unmet market needs and create value for homeowners, our customers and for James Hardie. How we embrace and embed innovation Our approach to innovation is driven by considerations of four key aspects: Quality of Life Sustainability Aesthetics Productivity James Hardie has been a global innovator for more than 125 years. We invented modern fiber cement siding products as a durable, low-maintenance alternative to wood and vinyl, and we remain driven to find better ways to build. We manufacture or sell our products in more than 20 countries, and have a depth and breadth of expertise to draw on as we develop new products. By applying a continuous improvement mindset to research and product development, we are able to deliver better value to our customers. This helps end users build better homes and more sustainable communities. We leverage our global scale and know-how with more than 100 R&D employees around the world. We are expanding our R&D capability further through the approval of two new pilot R&D facility expansions, in Fontana, California and Rosehill, Australia. Both are expected to be fully operational within 24 months. Our global innovation strategy is to develop market-driven innovation that also address unmet needs while expanding our portfolio of products. We not only innovate for our consumers but with our consumers. Since 2019 we have transformed the way we innovate, leveraging our global scale fiber cement and fiber gypsum expertise to deliver new high impact products that are based on homeowner insights and unmet market needs. Our innovation platforms are poised to deliver new designs and aesthetics so homeowners can be inspired with endless design possibilities to bring their dream home to reality. These designs are built on the key advantages of our fiber cement technology that delivers durability, low maintenance and non-combustibility while continuing to make these solutions easier to install to enhance labor productivity. MEGA TRENDS CONSUMER INSIGHTS WINNING PRODUCT CONCEPTS Focus on mega trends We focus on mega trends in the market and conduct in depth discovery and testing with homeowners to generate insights. We draw on three key global mega trends to inform our view of enduring value creation opportunities: 1. Labor shortage, particularly skilled labor, forms an opportunity to make sure our products are easy to use and quicker to install versus alternative products. 2. Affordable housing, driven by a lack of inventory and rising input costs requires that our innovations deliver value much greater than costs to enable home ownership for more people. 3. Urbanization, which shapes the needs of our communities, changing demographics and lifestyle preferences. With these trends in mind, we conduct in-depth discovery testing. Insights are then leveraged to prioritize product concepts that can truly deliver on unmet market needs and create values for James Hardie and its stakeholders. OUR PILLARS OUR PILLARS 4039 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

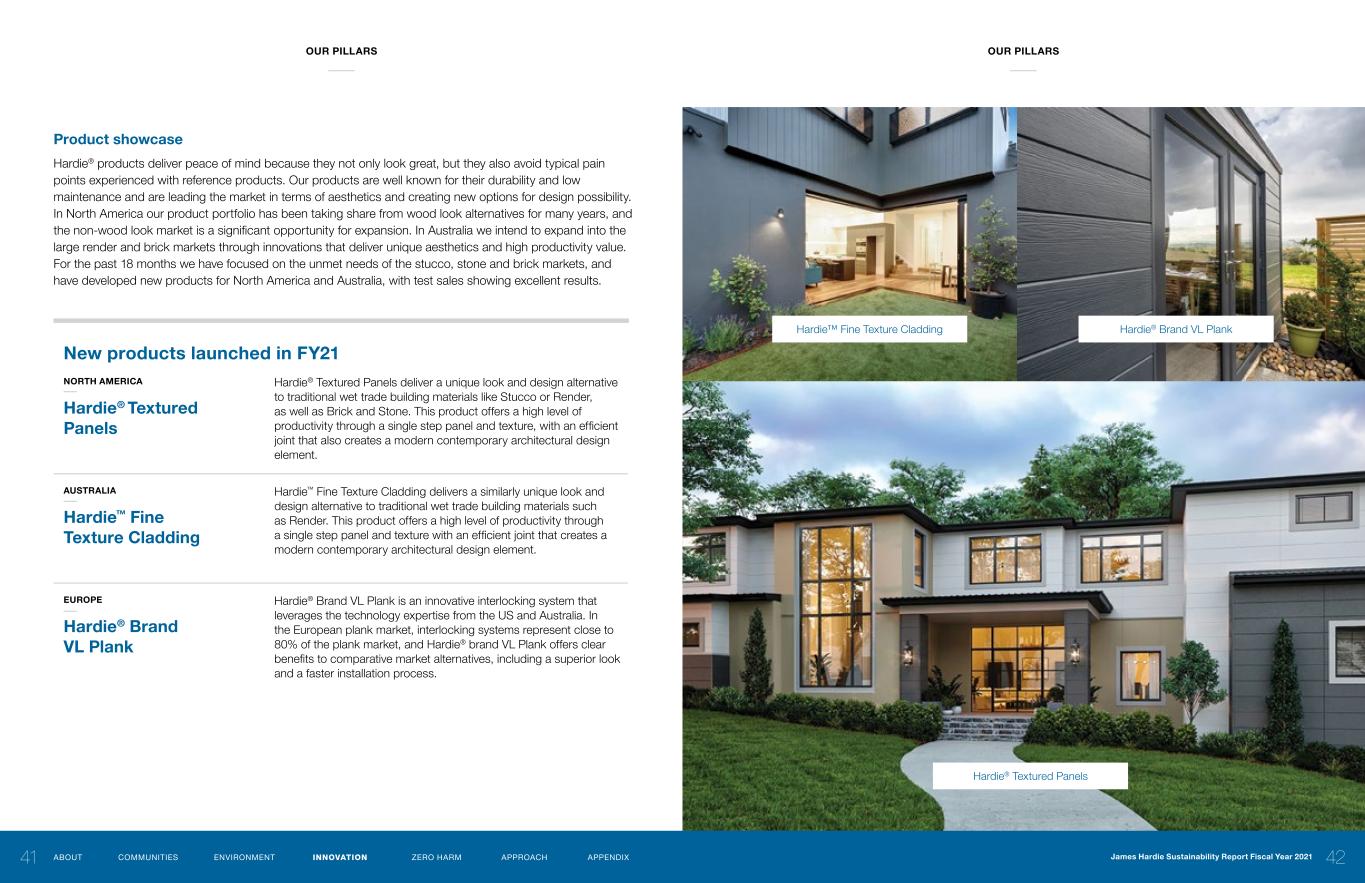

Hardie® Textured Panels Hardie® Brand VL PlankHardie™ Fine Texture Cladding Product showcase Hardie® products deliver peace of mind because they not only look great, but they also avoid typical pain points experienced with reference products. Our products are well known for their durability and low maintenance and are leading the market in terms of aesthetics and creating new options for design possibility. In North America our product portfolio has been taking share from wood look alternatives for many years, and the non-wood look market is a significant opportunity for expansion. In Australia we intend to expand into the large render and brick markets through innovations that deliver unique aesthetics and high productivity value. For the past 18 months we have focused on the unmet needs of the stucco, stone and brick markets, and have developed new products for North America and Australia, with test sales showing excellent results. New products launched in FY21 NORTH AMERICA Hardie® Textured Panels Hardie® Textured Panels deliver a unique look and design alternative to traditional wet trade building materials like Stucco or Render, as well as Brick and Stone. This product offers a high level of productivity through a single step panel and texture, with an efficient joint that also creates a modern contemporary architectural design element. AUSTRALIA Hardie™ Fine Texture Cladding Hardie™ Fine Texture Cladding delivers a similarly unique look and design alternative to traditional wet trade building materials such as Render. This product offers a high level of productivity through a single step panel and texture with an efficient joint that creates a modern contemporary architectural design element. EUROPE Hardie® Brand VL Plank Hardie® Brand VL Plank is an innovative interlocking system that leverages the technology expertise from the US and Australia. In the European plank market, interlocking systems represent close to 80% of the plank market, and Hardie® brand VL Plank offers clear benefits to comparative market alternatives, including a superior look and a faster installation process. OUR PILLARS OUR PILLARS 4241 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

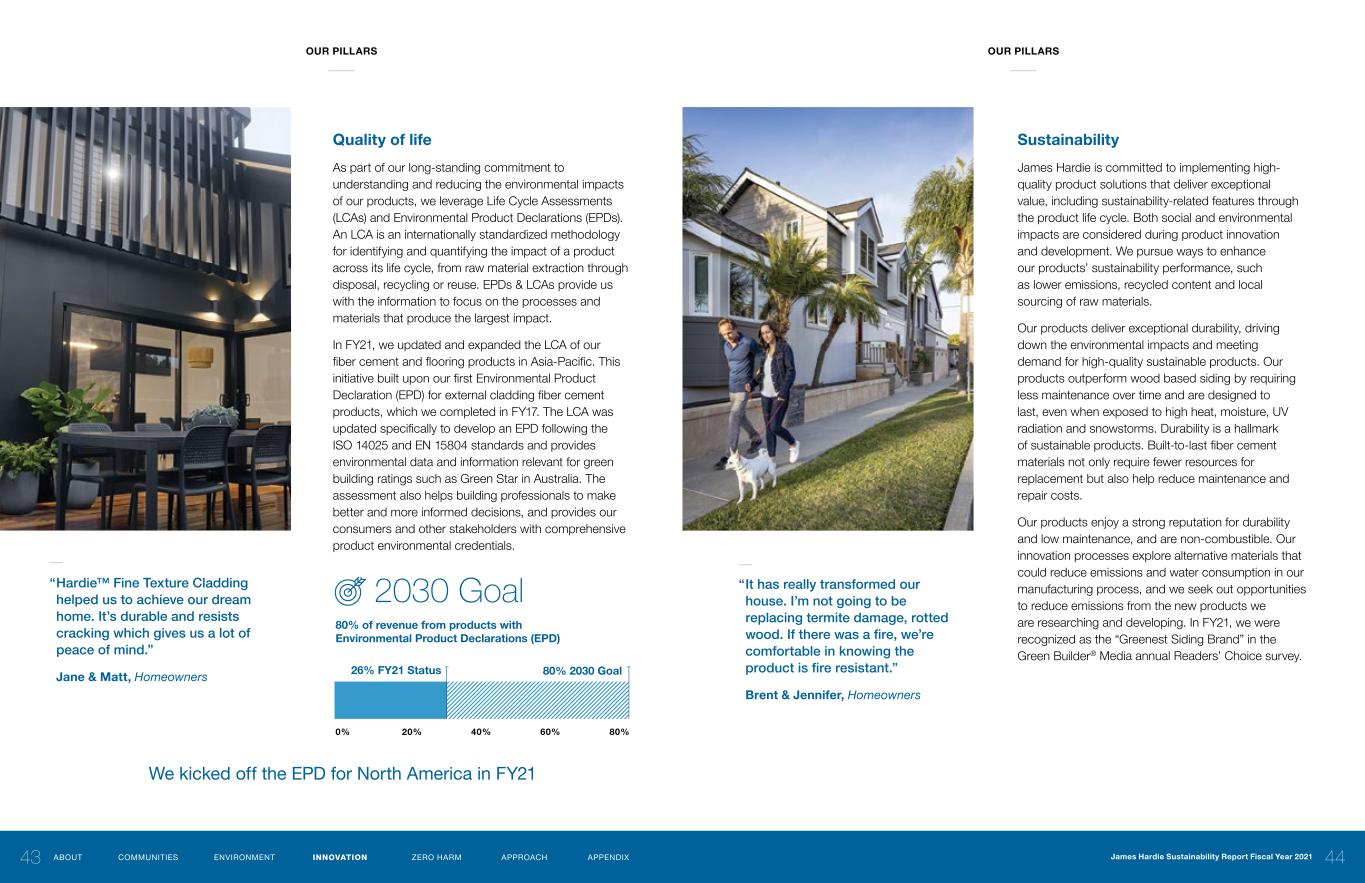

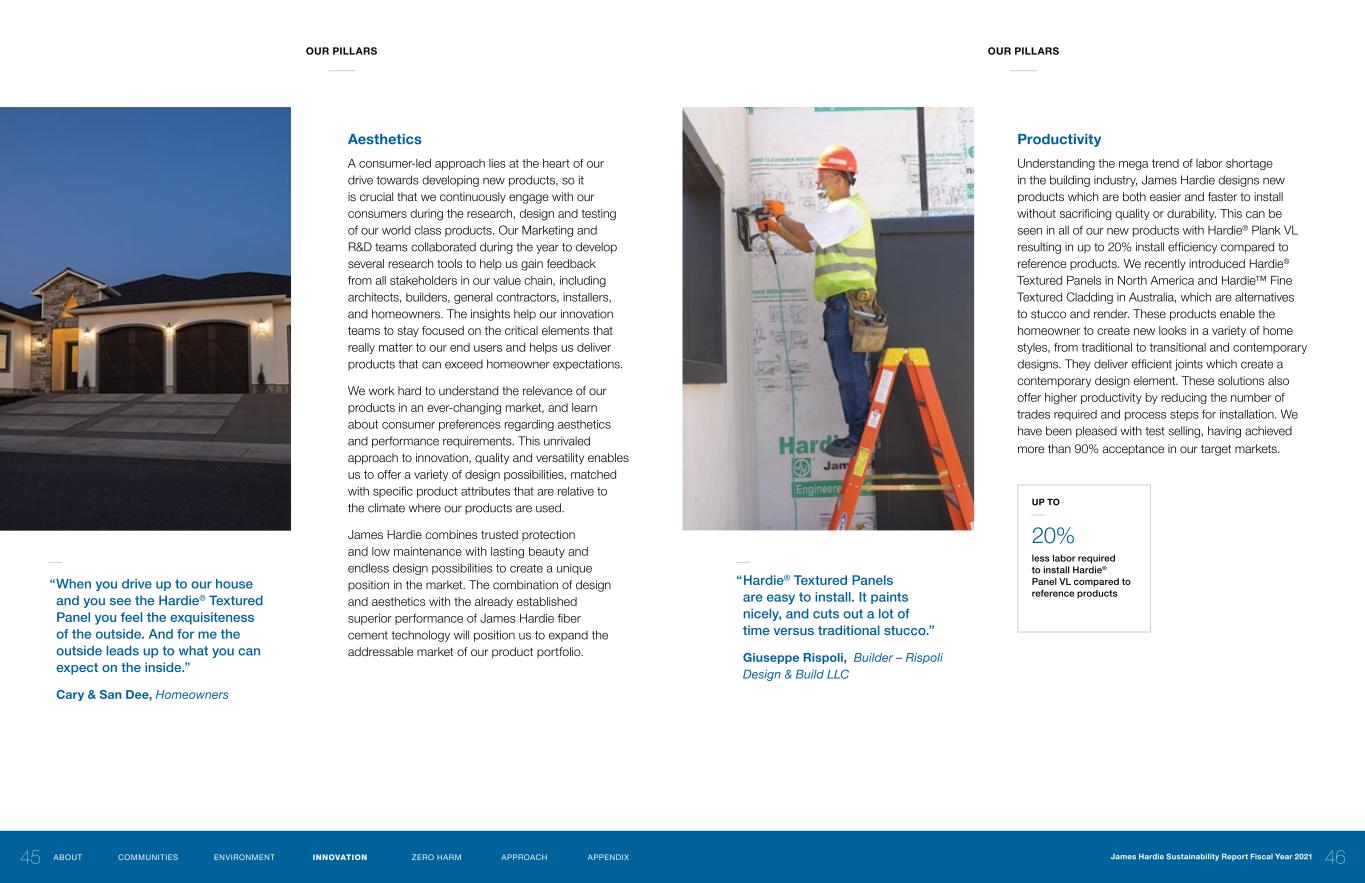

26% FY21 Status 80% 2030 Goal 0% 20% 40% 60% 80% 2030 Goal 80% of revenue from products with Environmental Product Declarations (EPD) Sustainability James Hardie is committed to implementing high- quality product solutions that deliver exceptional value, including sustainability-related features through the product life cycle. Both social and environmental impacts are considered during product innovation and development. We pursue ways to enhance our products’ sustainability performance, such as lower emissions, recycled content and local sourcing of raw materials. Our products deliver exceptional durability, driving down the environmental impacts and meeting demand for high-quality sustainable products. Our products outperform wood based siding by requiring less maintenance over time and are designed to last, even when exposed to high heat, moisture, UV radiation and snowstorms. Durability is a hallmark of sustainable products. Built-to-last fiber cement materials not only require fewer resources for replacement but also help reduce maintenance and repair costs. Our products enjoy a strong reputation for durability and low maintenance, and are non-combustible. Our innovation processes explore alternative materials that could reduce emissions and water consumption in our manufacturing process, and we seek out opportunities to reduce emissions from the new products we are researching and developing. In FY21, we were recognized as the “Greenest Siding Brand” in the Green Builder® Media annual Readers’ Choice survey. Quality of life As part of our long-standing commitment to understanding and reducing the environmental impacts of our products, we leverage Life Cycle Assessments (LCAs) and Environmental Product Declarations (EPDs). An LCA is an internationally standardized methodology for identifying and quantifying the impact of a product across its life cycle, from raw material extraction through disposal, recycling or reuse. EPDs & LCAs provide us with the information to focus on the processes and materials that produce the largest impact. In FY21, we updated and expanded the LCA of our fiber cement and flooring products in Asia-Pacific. This initiative built upon our first Environmental Product Declaration (EPD) for external cladding fiber cement products, which we completed in FY17. The LCA was updated specifically to develop an EPD following the ISO 14025 and EN 15804 standards and provides environmental data and information relevant for green building ratings such as Green Star in Australia. The assessment also helps building professionals to make better and more informed decisions, and provides our consumers and other stakeholders with comprehensive product environmental credentials. “ Hardie™ Fine Texture Cladding helped us to achieve our dream home. It’s durable and resists cracking which gives us a lot of peace of mind.” Jane & Matt, Homeowners “ It has really transformed our house. I’m not going to be replacing termite damage, rotted wood. If there was a fire, we’re comfortable in knowing the product is fire resistant.” Brent & Jennifer, Homeowners We kicked off the EPD for North America in FY21 OUR PILLARS OUR PILLARS 4443 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

Aesthetics A consumer-led approach lies at the heart of our drive towards developing new products, so it is crucial that we continuously engage with our consumers during the research, design and testing of our world class products. Our Marketing and R&D teams collaborated during the year to develop several research tools to help us gain feedback from all stakeholders in our value chain, including architects, builders, general contractors, installers, and homeowners. The insights help our innovation teams to stay focused on the critical elements that really matter to our end users and helps us deliver products that can exceed homeowner expectations. We work hard to understand the relevance of our products in an ever-changing market, and learn about consumer preferences regarding aesthetics and performance requirements. This unrivaled approach to innovation, quality and versatility enables us to offer a variety of design possibilities, matched with specific product attributes that are relative to the climate where our products are used. James Hardie combines trusted protection and low maintenance with lasting beauty and endless design possibilities to create a unique position in the market. The combination of design and aesthetics with the already established superior performance of James Hardie fiber cement technology will position us to expand the addressable market of our product portfolio. Productivity Understanding the mega trend of labor shortage in the building industry, James Hardie designs new products which are both easier and faster to install without sacrificing quality or durability. This can be seen in all of our new products with Hardie® Plank VL resulting in up to 20% install efficiency compared to reference products. We recently introduced Hardie® Textured Panels in North America and Hardie™ Fine Textured Cladding in Australia, which are alternatives to stucco and render. These products enable the homeowner to create new looks in a variety of home styles, from traditional to transitional and contemporary designs. They deliver efficient joints which create a contemporary design element. These solutions also offer higher productivity by reducing the number of trades required and process steps for installation. We have been pleased with test selling, having achieved more than 90% acceptance in our target markets. “ Hardie® Textured Panels are easy to install. It paints nicely, and cuts out a lot of time versus traditional stucco.” Giuseppe Rispoli, Builder – Rispoli Design & Build LLC “ When you drive up to our house and you see the Hardie® Textured Panel you feel the exquisiteness of the outside. And for me the outside leads up to what you can expect on the inside.” Cary & San Dee, Homeowners UP TO 20% less labor required to install Hardie® Panel VL compared to reference products OUR PILLARS OUR PILLARS 4645 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

ZERO HARM Safety is a non-negotiable value for our business success Our commitment Safety is a non-negotiable value for business success, and we prioritize the protection of our people and those who use or interact with our products. Our goal Continuous improvement year-over-year Recognized for world class safety Our approach Safe people Safe places Safe systems FY21 performance 0.83 total recordable incident rate (TRIR) 0.51 total days away, restricted or transferred (DART) rate AT-A-GLANCE 4847 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

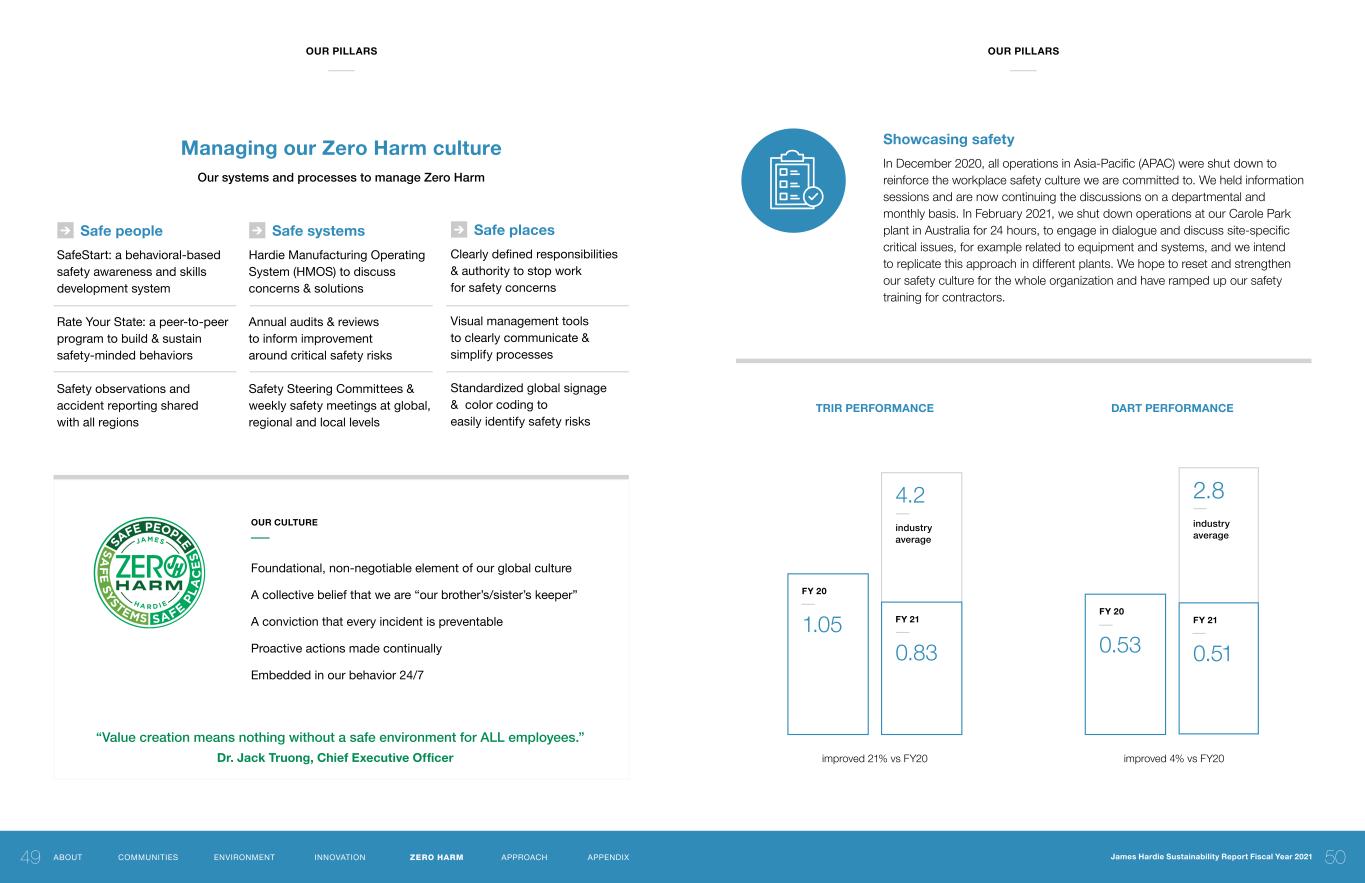

2.8 industry average Managing our Zero Harm culture Our systems and processes to manage Zero Harm Safe people SafeStart: a behavioral-based safety awareness and skills development system Rate Your State: a peer-to-peer program to build & sustain safety-minded behaviors Safety observations and accident reporting shared with all regions Safe systems Hardie Manufacturing Operating System (HMOS) to discuss concerns & solutions Annual audits & reviews to inform improvement around critical safety risks Safety Steering Committees & weekly safety meetings at global, regional and local levels Safe places Clearly defined responsibilities & authority to stop work for safety concerns Visual management tools to clearly communicate & simplify processes Standardized global signage & color coding to easily identify safety risks Showcasing safety In December 2020, all operations in Asia-Pacific (APAC) were shut down to reinforce the workplace safety culture we are committed to. We held information sessions and are now continuing the discussions on a departmental and monthly basis. In February 2021, we shut down operations at our Carole Park plant in Australia for 24 hours, to engage in dialogue and discuss site-specific critical issues, for example related to equipment and systems, and we intend to replicate this approach in different plants. We hope to reset and strengthen our safety culture for the whole organization and have ramped up our safety training for contractors. TRIR PERFORMANCE improved 21% vs FY20 improved 4% vs FY20 4.2 industry average FY 21 0.83 FY 20 1.05 FY 20 0.53 FY 21 0.51 DART PERFORMANCE Foundational, non-negotiable element of our global culture A collective belief that we are “our brother’s/sister’s keeper” A conviction that every incident is preventable Proactive actions made continually Embedded in our behavior 24/7 OUR CULTURE “Value creation means nothing without a safe environment for ALL employees.” Dr. Jack Truong, Chief Executive Officer OUR PILLARS OUR PILLARS 5049 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

DISTRIBUTED 60,000 masks to our workforce and their families ADMINISTERED 3,918 proactive tests to ensure employee safety and business continuity ADDED 80 hours paid COVID-19 sick and recovery leave per employee PROVIDED 525,000+ lunches to employees through our free lunch program during the pandemic Precautionary & proactive COVID-19 measures The importance of Zero Harm and protecting the health and wellbeing of our people was the top priority across all our operations. Our response to COVID-19 was rapid, well-controlled and proactive. We implemented appropriate measures within the context of local situations and, due to our presence in Europe, were able to establish support procedures in North America ahead of US Centers for Disease Control and Prevention protocols. Measures taken include: CONDUCTED Pre-emptive testing, contact tracing and quarantine procedures ESTABLISHED Onsite lunch program in North America to reduce the risk of infection and support local businesses INCREASED Child and family care support for employees (remote work, time off, financial assistance) COMMUNICATED Important CDC and local health information to employees, including hosting webinars with physicians SUPPORTED Employees and their families with onsite and and web based mental health resources PROVIDED EPA-approved disinfectants for home use SHARED Best practices and personal protective equipment (PPE) with customers and suppliers MODIFIED All facilities to enable effective social distancing practices CREATED Hygiene care packages, PPE and cleaning products for employees’ home use Zero Harm response to COVID-19 James Hardie’s response to COVID-19 was swift and enabled the business not only to survive but to thrive in unprecedented circumstances. Our Zero Harm culture and our Hardie Manufacturing Operating System enabled us to be flexible and respond to the demands imposed by the virus. We were able to put our people and their families first, ensuring they received appropriate protective equipment and products, both at work and for their homes. We also provided physical and mental health care support and exceeded regulatory requirements in terms of illness-related leave. We provided daily lunches, which we purchased from local businesses, to minimize the risk of our people contracting the virus and also to support our struggling local communities. The success of our approach and our safety protocols allowed us to keep our people safe and have our business thrive throughout the pandemic. OUR PILLARS OUR PILLARS 5251 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

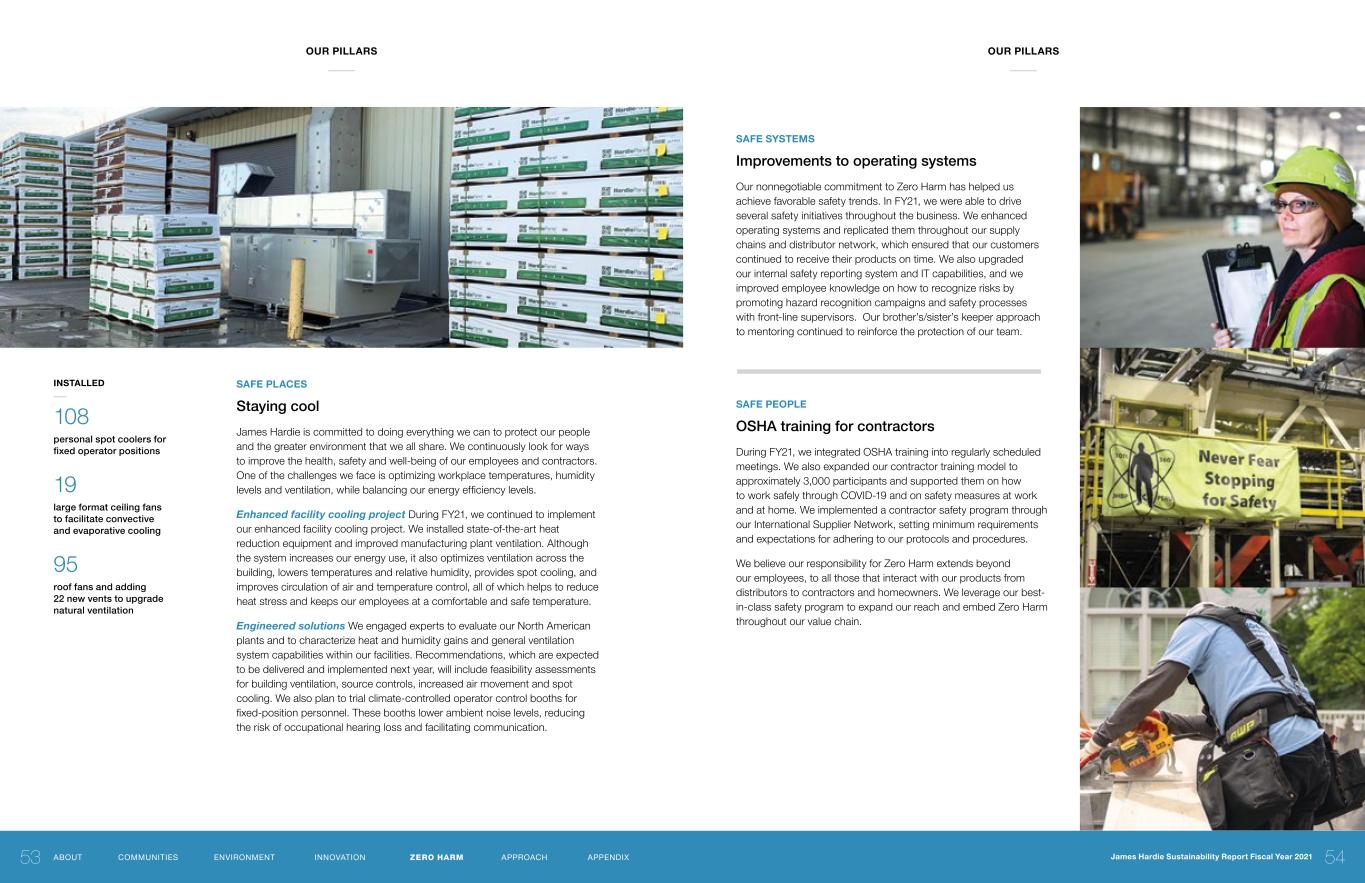

SAFE PLACES Staying cool James Hardie is committed to doing everything we can to protect our people and the greater environment that we all share. We continuously look for ways to improve the health, safety and well-being of our employees and contractors. One of the challenges we face is optimizing workplace temperatures, humidity levels and ventilation, while balancing our energy efficiency levels. Enhanced facility cooling project During FY21, we continued to implement our enhanced facility cooling project. We installed state-of-the-art heat reduction equipment and improved manufacturing plant ventilation. Although the system increases our energy use, it also optimizes ventilation across the building, lowers temperatures and relative humidity, provides spot cooling, and improves circulation of air and temperature control, all of which helps to reduce heat stress and keeps our employees at a comfortable and safe temperature. Engineered solutions We engaged experts to evaluate our North American plants and to characterize heat and humidity gains and general ventilation system capabilities within our facilities. Recommendations, which are expected to be delivered and implemented next year, will include feasibility assessments for building ventilation, source controls, increased air movement and spot cooling. We also plan to trial climate-controlled operator control booths for fixed-position personnel. These booths lower ambient noise levels, reducing the risk of occupational hearing loss and facilitating communication. SAFE SYSTEMS Improvements to operating systems Our nonnegotiable commitment to Zero Harm has helped us achieve favorable safety trends. In FY21, we were able to drive several safety initiatives throughout the business. We enhanced operating systems and replicated them throughout our supply chains and distributor network, which ensured that our customers continued to receive their products on time. We also upgraded our internal safety reporting system and IT capabilities, and we improved employee knowledge on how to recognize risks by promoting hazard recognition campaigns and safety processes with front-line supervisors. Our brother’s/sister’s keeper approach to mentoring continued to reinforce the protection of our team. SAFE PEOPLE OSHA training for contractors During FY21, we integrated OSHA training into regularly scheduled meetings. We also expanded our contractor training model to approximately 3,000 participants and supported them on how to work safely through COVID-19 and on safety measures at work and at home. We implemented a contractor safety program through our International Supplier Network, setting minimum requirements and expectations for adhering to our protocols and procedures. We believe our responsibility for Zero Harm extends beyond our employees, to all those that interact with our products from distributors to contractors and homeowners. We leverage our best- in-class safety program to expand our reach and embed Zero Harm throughout our value chain. INSTALLED 108 personal spot coolers for fixed operator positions 19 large format ceiling fans to facilitate convective and evaporative cooling 95 roof fans and adding 22 new vents to upgrade natural ventilation OUR PILLARS OUR PILLARS 5453 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

We are committed to managing and reporting on what matters most to our stakeholders OUR STAKEHOLDERS & MATERIAL TOPICS Our material topicsJames Hardie’s most recent materiality assessment identified, prioritized and validated the company’s material topics and associated impacts. Setting a material threshold, the process resulted in nine key topics being designated for management and reporting. We’ve since combined the topics of energy and emissions resulting in eight key topics. Our strategic and operational focus also aligns with and contributes to the achievement of several Sustainable Development Goals (SDGs). AT-A-GLANCE 5655 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

Stakeholder engagement James Hardie is committed to reporting on what matters most to our stakeholders so it is essential that we engage with them to understand their opinions and concerns. Our key stakeholders include employees, regulatory agencies, investors, municipalities, customers and suppliers, and we tailor our methods of engagement for each stakeholder to maximize the opportunity for dialogue. Our material topics In FY20, we undertook our first formal materiality assessment to identify, prioritize and validate topics for reporting and informing our sustainability strategy. The process, which was led by our Global ESG Leader and supported by external sustainability consultants, applied the GRI Reporting Principles for defining report content (stakeholder inclusiveness, sustainability context, materiality and completeness). Stakeholder interests and perspectives were included in the process, some by proxy (such as employees, customers and local communities) and others through direct consultation (global and regional senior leaders from across the company and institutional investors). Identification & prioritization Using the principle of sustainability context, and through a lens of sustainable development and stakeholder interests, we identified the ESG topics relevant to our business and operations. An initial list of relevant topics and their definitions drew on a range of sources, including: UNITED NATIONS SUSTAINABLE DEVELOPMENT GOALS GRI STANDARDS PEER BENCHMARKING, INDUSTRY INITIATIVES AND SECTORAL TRENDS STAKEHOLDER FEEDBACK PREVIOUS SUSTAINABILITY REPORTS SASB CONSTRUCTION MATERIALS STANDARDS “ By defining its material topics, James Hardie can focus on the critical ESG issues most relevant to the company. Our ESG program is structured around four pillars that align with our material topics and are underpinned by our commitment to sustainable development and the UN Sustainable Development Goals.” Shamim Imani, Global ESG Leader For each topic, we evaluated the significance of the associated impacts and level of stakeholder interest and strategic priority. We quantified topics for prioritization based on factors drawn from the GRI Materiality principle and informed by further desktop research, organizational factors, and interviews with institutional investors and with more than 30 cross- functional internal stakeholders from our North American, Asia Pacific and European regions. We applied the GRI Materiality principle to evaluate topics, plotted topics on a materiality matrix and set a threshold for reporting. Validation To ensure completeness, we reviewed and refined initial results with internal stakeholders. The Global ESG Lead consulted with the ESG Steering Committee and senior executives on the proposed list of material topics. Final results were vetted and validated. OUR STAKEHOLDERS & MATERIAL TOPICS OUR STAKEHOLDERS & MATERIAL TOPICS 5857 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX

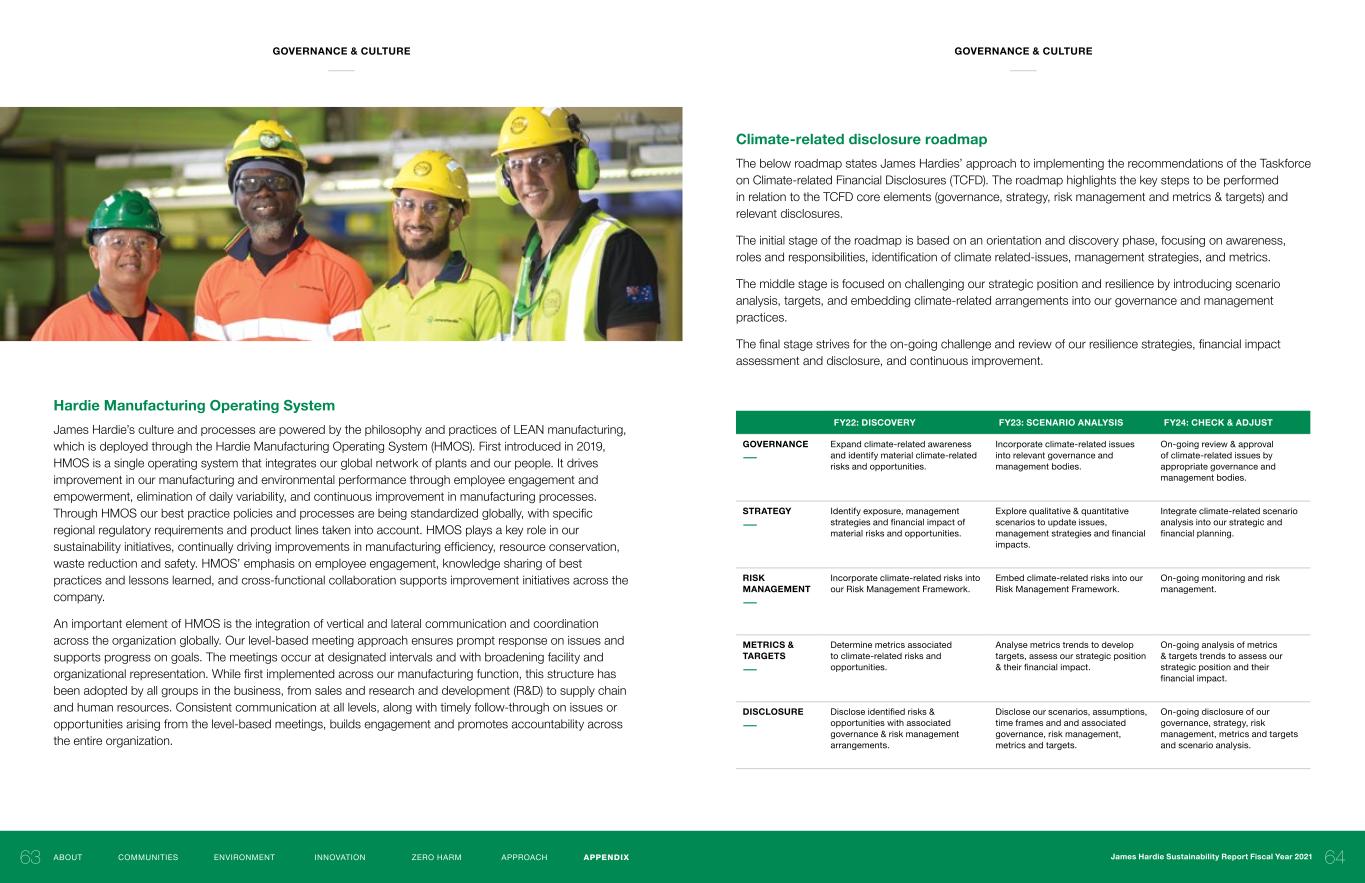

Our people and management systems protocols ensure our business resilience BUSINESS RESILIENCE Throughout FY21, James Hardie proved its business resilience in the face of several unprecedented challenges. We rapidly adapted to the global disruptions caused by COVID-19 and a severe winter storm that paralyzed Texas. These crises accelerated progress on our integration initiatives, while our flexibility and robust systems enabled us to pivot and streamline many of our processes in a safe and productive manner. We not only survived but thrived. Our overwhelming success is a testament to the strength and agility of our people and our systems. Our Hardie Manufacturing Operating System allowed us to operate as one business, with elevated communication and systematic and flexible management. We kept our people safe and continued to serve our customers. We supported many local community businesses, distributors, and suppliers while collaborating closely with them to share our safety protocols and extend our partnerships. “ The resilience and flexibility of our people and our processes enable us to adapt to unexpected disruptions that challenge our business continuity and future development.” Dr. Jack Truong Chief Executive Officer Texas winter storm In February 2021, Texas experienced an unprecedented winter storm that created rolling power outages and suspended access to natural gas, both of which are critical to running a 24/7 operation. Leveraging our Hardie Manufacturing Operating System (HMOS), we quickly escalated the effects from the operators on the floor through to our Executive Leadership Team. Thanks to our people and integrated systems, we were able to leverage knowledge and experience from colder weather plants to effectively manage the situation. By leveraging our scale, we successfully made changes to our network of plants, moving production to alternative facilities as appropriate. This was a team effort from the plants and across all functions of the company including involvement from our suppliers and customers. This concerted effort helped us to adapt and continue to serve our customers seamlessly and deliver business results. Responding to COVID-19 The collective efforts of our employees, their families, and our suppliers and customers, combined with our Hardie Manufacturing Operating System and global Zero Harm procedures, enabled our business to thrive while minimizing the impacts of COVID-19. We built organizational muscle and leadership and more deeply embedded cross-functional teamwork. With significant investment and our continuously improving safety protocols, training and communication, we kept our people safe. In FY21, our meeting methods and trainings were adjusted in an effort that exceeded regulatory obligations. Employees were provided additional paid hours for pandemic-related illness to ensure that no one came to work sick. We redeployed employees and contractors, leveraging strengths to continue delivering value in this new environment. This approach enabled us to ramp up quickly and exceed performance expectations. 60,000+ masks distributed to our workforce and their families 3,918 proactive tests to ensure employee safety and business continuity 80 hours additional paid COVID-19 sick and recovery leave per employee 525,000+ lunches provided to employees through our free daily lunch program during the pandemic AT-A-GLANCE 6059 James Hardie Sustainability Report Fiscal Year 2021ABOUT COMMUNITIES ENVIRONMENT INNOVATION ZERO HARM APPROACH APPENDIX