James Hardie Releases Annual Sustainability Report Company announces progress in building resilience through process integration, product innovation and strengthening communities SYDNEY & CHICAGO, September 3, 2025 - James Hardie Industries plc (NYSE / ASX : JHX) ("James Hardie" or the "Company"), a leading provider of exterior home and outdoor living solutions, and a company inspiring how communities design, build and grow, today released its latest annual sustainability report entitled “Building Resilience.” “At James Hardie, sustainability is foundational to how we do business. We are continuing to make progress, evolve and innovate to ensure homes are built to last,” said Aaron Erter, Chief Executive Officer. “Sustainability is a journey, and this continues with our recent acquisition of The AZEK® Company in July 2025. As the industry leader in exterior home and outdoor living solutions, we have never been better positioned to explore a variety of ways we can improve our communities and our planet. At James Hardie we are constantly working towards our purpose of Building a Better Future for All™.” The report features initiatives to advance the Company’s purpose and details progress across the four primary pillars of the Company’s environmental, social and governance (ESG) strategy: Zero Harm, Planet, Innovation and Communities. Highlights from the report for fiscal year 2025 include: Integration into Business Processes • Sustainability strategies continue to be integrated into the Hardie Manufacturing Operating System (HMOS). • Short-term internal natural gas targets were set for each region, helping drive the reduction of Scope 1+2 emissions by 14 percent in fiscal year 2025 from the calendar year 2021 baseline. Circular Supply Chain • Efforts to reduce waste and create a circular supply chain for fiber cement products in North America plants diverted over 11 percent of manufacturing waste from local landfills in fiscal year 2025. • In the Asia Pacific region, James Hardie eliminated 98 percent of waste material sent to landfills by either recycling it back into production processes or sending it to local companies to keep waste materials in the value stream. Zero Harm • Over a three-year period, James Hardie is investing more than $75 million in strategic safety infrastructure projects globally. • Safety standards for energy control processes, machine guarding, working from heights and electrical safety were developed and independently approved in North America and Asia Pacific. Product Innovation • James Hardie debuted the TimberHue™ Collection in North America, featuring two-tone, premium finishes in eight authentic wood-look colors – engineered to withstand harsh weather and made with noncombustible* James Hardie technology. In addition, its long-

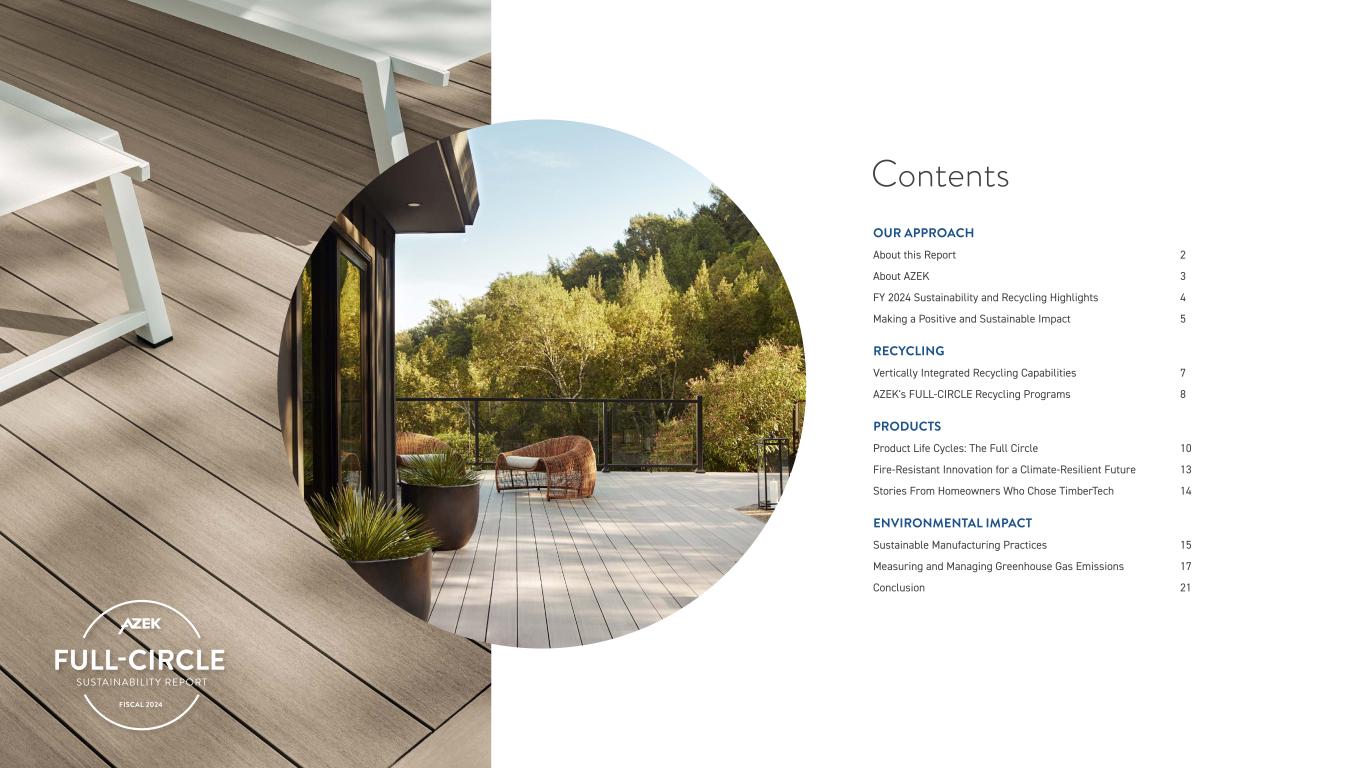

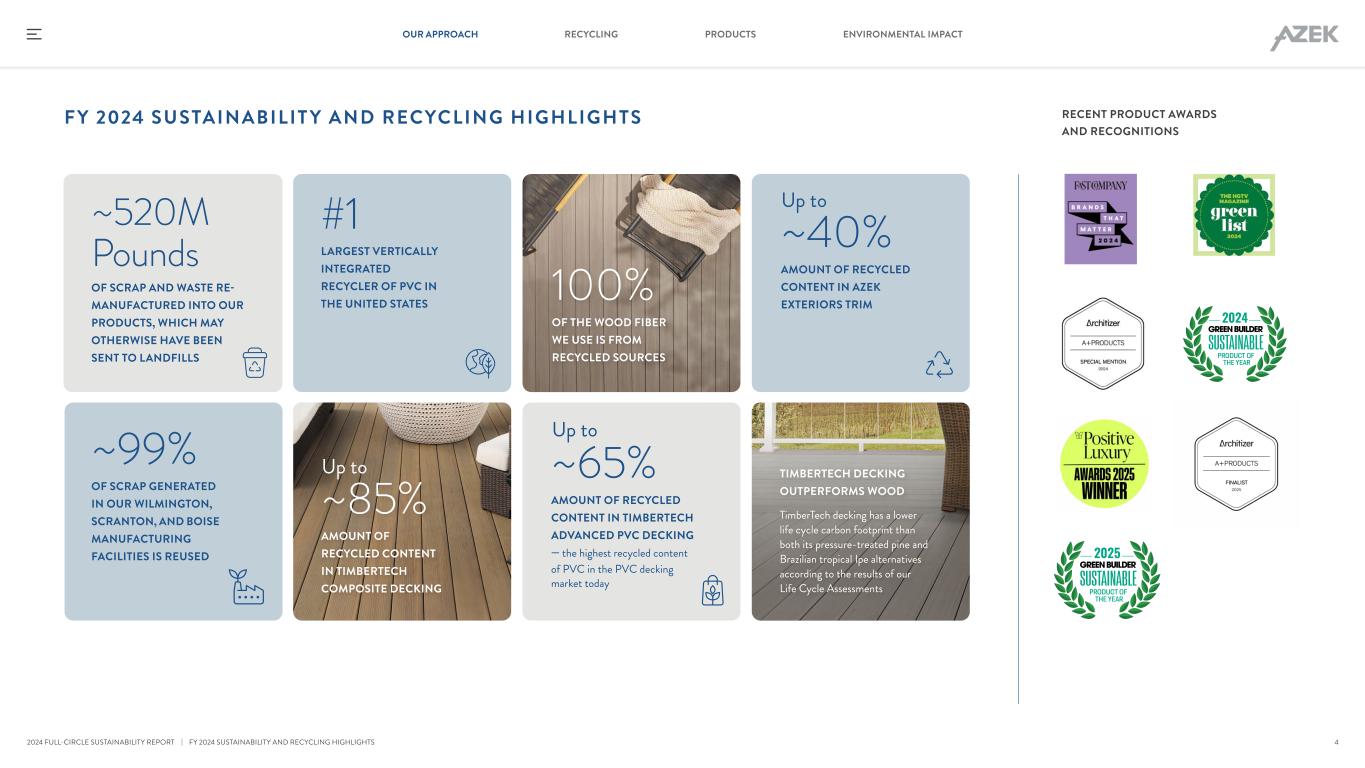

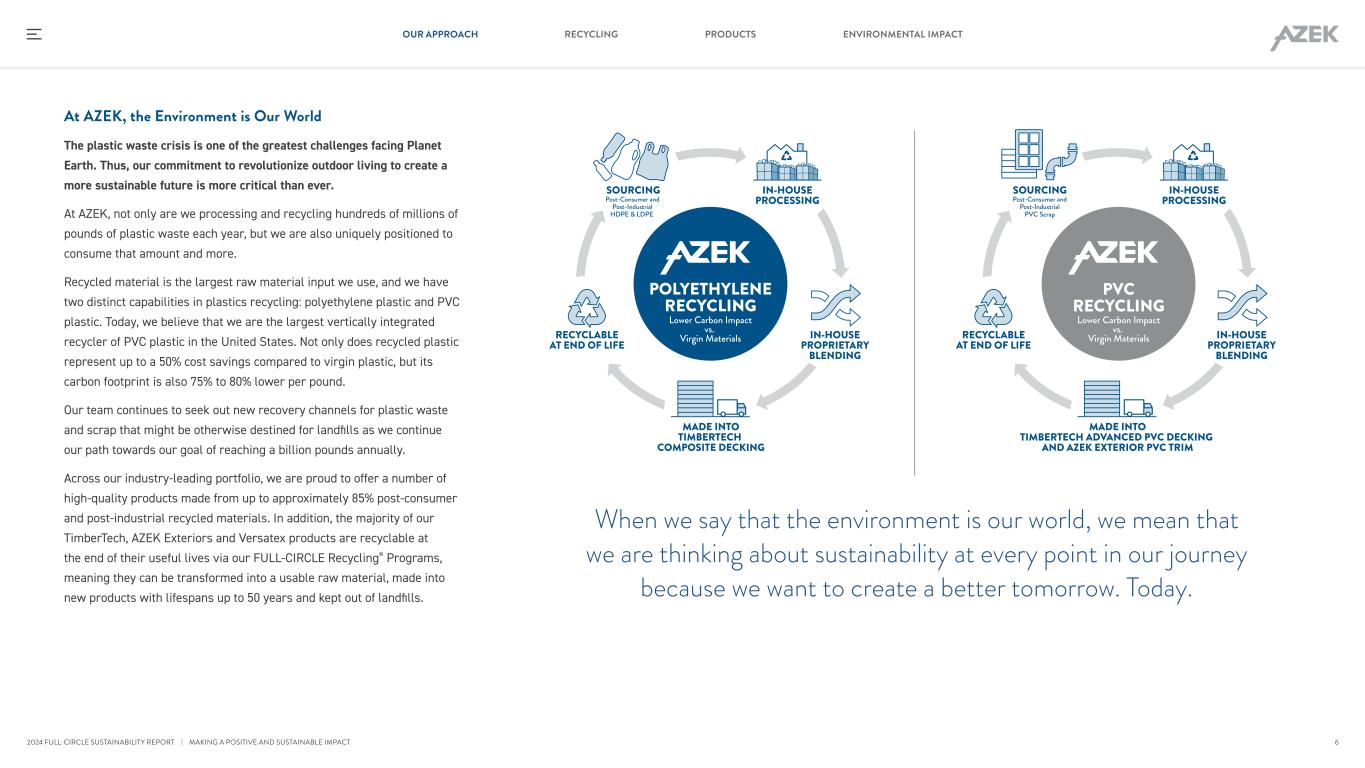

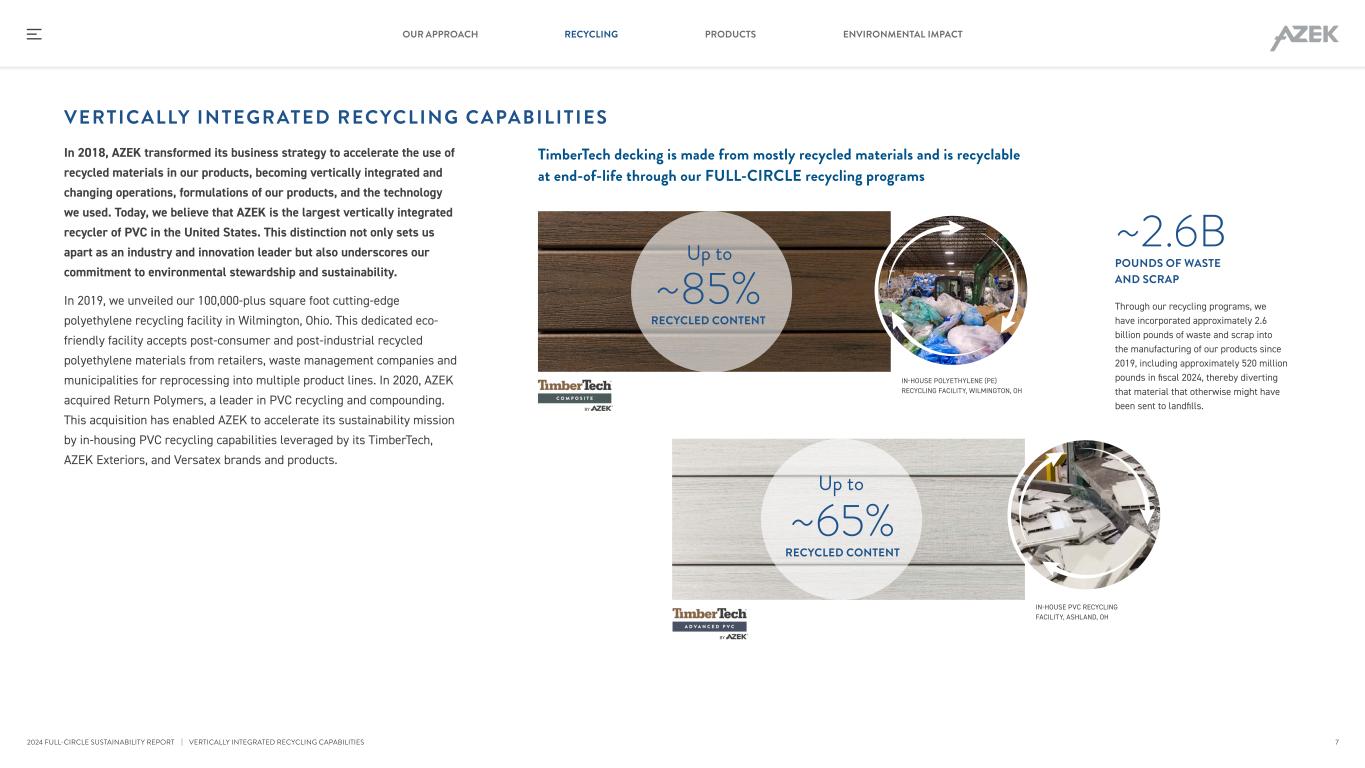

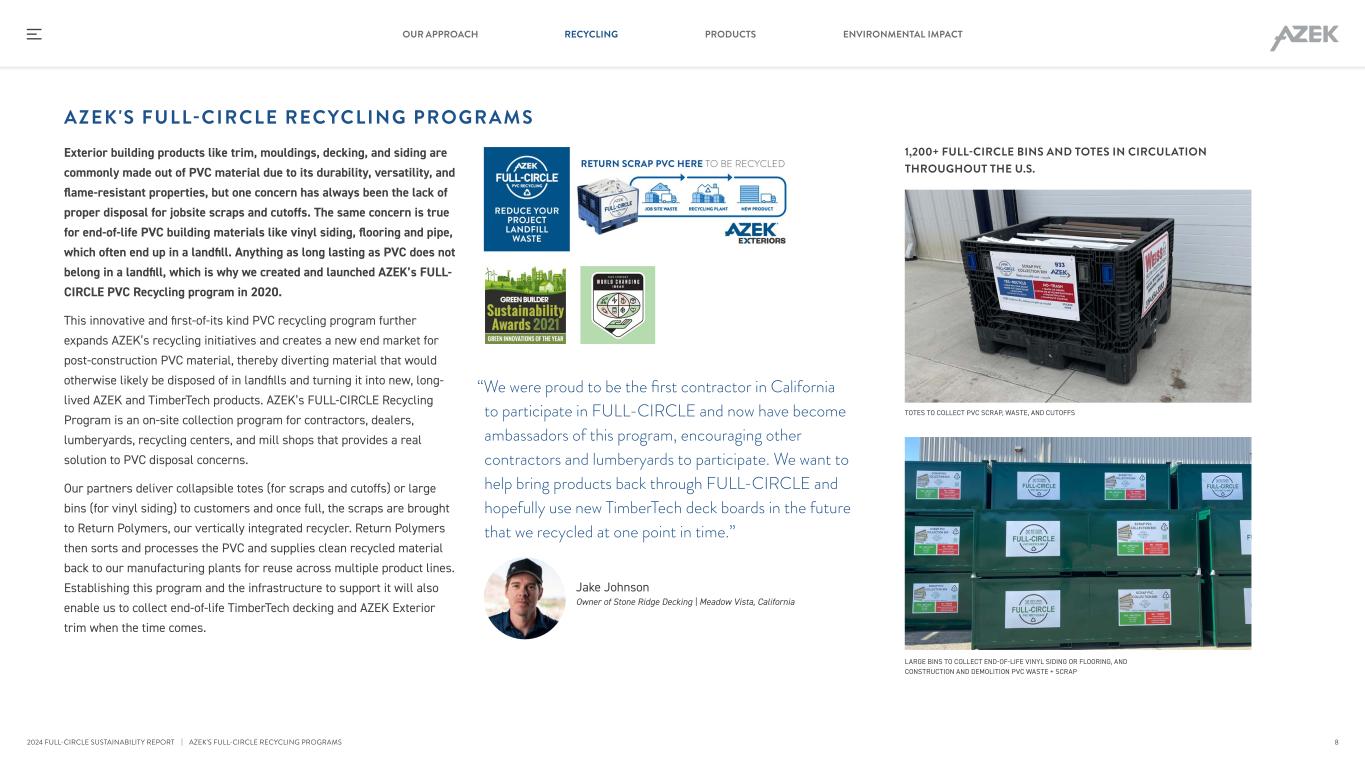

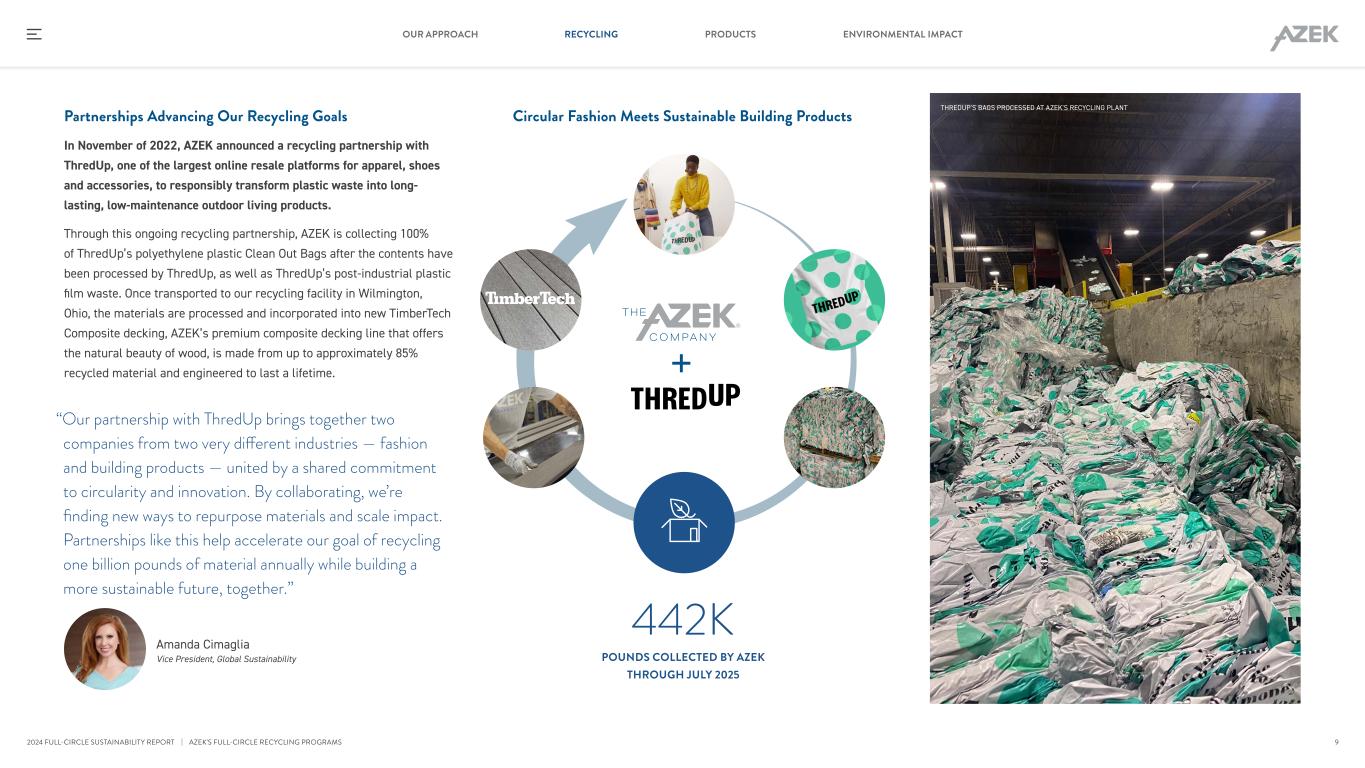

lasting performance reduces the need for replacement over time, conserving materials and resources. • The Hardie™ Architectural Collection expanded to include Hardie® Artisan® Siding, featuring extra-thick lap boards and deep shadow lines for a natural wood aesthetic with the strength and resilience of fiber cement, providing superior overall durability to help protect homes from fire damage while delivering a long-lasting, low-maintenance solution that supports more sustainable home exteriors. • In Europe, fermacell® Therm25™, an easy-to-install fiber gypsum product, has lower CO2 emissions compared to conventional flooring and incorporates recycled gypsum, reducing landfill waste and reliance on mined materials. • In the United States, Green Builder Media recognized James Hardie as an innovation and brand leader, naming Hardie® Artisan® Trim as a 2025 Sustainable Product of the Year for its distinctive design, superior performance and lasting value. Respecting Human Rights • James Hardie launched a global human rights policy and completed the first salient issues review, conducting on-site social compliance audits of the few tier-one suppliers in high-risk environments. Stronger Workforce • The launch of the BuildWell program is helping to create a culture of well-being, where employees are supported with education, resources and opportunities for their physical, mental, social and financial well-being, tailored to the specific needs of employees in different regions. Stronger Communities • James Hardie contributed $1.65 billion in economic value to the communities in which it operates through capital expenditures at plants and by investing in employees, local ecosystems and across the supplier base. • James Hardie continued its global collaboration with Habitat for Humanity® International, and provided 29 Habitat Strong grants to build affordable and climate-resilient homes in fiscal year 2025. Integrating with The AZEK® Company As announced in July 2025, James Hardie successfully completed its previously announced acquisition of The AZEK® Company (“AZEK”). James Hardie now features a portfolio of high- performance, low-maintenance exterior and outdoor living brands, including Hardie®, TimberTech®, AZEK® Exteriors, Versatex®, fermacell®, StruXure®, Ultralox® and Intex®. AZEK® embeds sustainability into every stage of its operations, from material sourcing and manufacturing to product durability and end-of-life solutions. Guided by a full-circle approach, AZEK® transforms waste and scrap into high-performance, long-lasting materials and aims to incorporate one billion pounds of recycled content into its manufacturing annually. Its latest and final stand-alone FULL-CIRCLE report highlighting progress toward environmental and recycling initiatives during AZEK®’s fiscal 2024 is available here. “As we continue to integrate with AZEK®, we are harnessing our collective strengths to advance our sustainability leadership and position the combined company for even greater impact. This

work is shaping the next generation of our sustainability goals, and we look forward to sharing more on this important topic in the future,” said Amanda Cimaglia, Vice President, Global Sustainability. Building Resilience James Hardie’s sustainability goals align directly with issues that matter most to its stakeholders and overall corporate objectives. The Company’s sustainability strategy is driven through cross- functional collaboration, including research and development, engineering, manufacturing, finance and human resources leadership. In fiscal year 2023, James Hardie adopted new, more ambitious sustainability goals to help track and assess progress. In fiscal year 2024, the Company set near-term regional targets that roll up to overall longer-term goals. Each regional president is held accountable for attaining these targets in the region and is provided funding in the regional budget to support initiatives at the local level. As a result, the entire organization is engaged in and committed to these goals. *Hardie® fiber cement products are noncombustible and/or have a Class A fire rating when tested in accordance with ASTM E84. Fiber cement fire resistance does not extend to applied paints or coatings, which may be damaged or char when exposed to flames. The use of noncombustible siding, combined with other fire mitigation measures, may help harden a home against external fire. ### For more information about James Hardie Building Products Inc., visit www.jameshardie.com. About James Hardie James Hardie Industries plc is the industry leader in exterior home and outdoor living solutions, with a portfolio that includes fiber cement, fiber gypsum, and composite and PVC decking and railing products. Products offered by James Hardie are engineered for beauty, durability, and climate resilience, and include trusted brands like Hardie®, TimberTech®, AZEK® Exteriors, Versatex®, fermacell® and StruXure®. With a global footprint, the James Hardie portfolio is marketed and sold throughout North America, Europe, Australia and New Zealand. James Hardie Industries plc is incorporated and existing under the laws of Ireland. As an Irish plc, James Hardie is governed by the Irish Companies Act. James Hardie’s principal executive offices are located at 1st Floor, Block A, One Park Place, Upper Hatch Street, Dublin 2, D02 FD79, Ireland. For more information and media resources, visit JamesHardie.com/about-us/media resources./about-us/media-resources. For investor information, please visit ir.jameshardie.com.au. Connect with James Hardie on social media: LinkedIn Instagram

Facebook X (formerly Twitter) Forward-Looking Statements This Media Release contains forward-looking statements and information that are necessarily subject to risks, uncertainties and assumptions. Additional important factors relating to the Company that could cause actual results to differ materially from those reflected in forward- looking statements include, but are not limited to, the risks and uncertainties set forth in Section 3 "Risk Factors" in the Company’s Annual Report on Form 20-F for the fiscal year ended March 31, 2025 (the “Company 2025 Annual Report”); changes in general economic, political, governmental and business conditions globally and in the countries in which the Company does business; changes in interest rates; changes in inflation rates; changes in exchange rates; the level of construction generally; changes in cement demand and prices; changes in raw material and energy prices; changes in business strategy and various other factors. Should one or more of these risks or uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described herein. James Hardie assumes no obligation to update or correct the information contained in this Media Release except as required by law. This media release has been authorized by the James Hardie Board of Directors. END Investor and Media Contact Joe Ahlersmeyer, CFA Vice President, Investor Relations Telephone: +1 773-970-1213 Email: mailto:[email protected] James Hardie Industries plc is a limited liability company incorporated in Ireland with its registered office at 1st Floor, Block A, One Park Place, Upper Hatch Street, Dublin 2, D02 FD79, Ireland.

Building Resilience SUSTAINABILITY REPORT | FISCAL YEAR 2025

At James Hardie, we pride ourselves on providing products that help craft more resilient, durable homes and buildings. Our sustainability commitments are integrated into our business operations, governance structure and company culture. Our fifth annual Sustainability Report provides an update on our programs and progress from the last fiscal year. The voices of our team members — from front line employees to leadership — help tell the story of how we are living our purpose: Building a Better Future for All™. Table of Contents Message from our CEO 2 About James Hardie 3 Our Sustainability Goals 4 Our Supply Chain 5 Our People 8 Our Operations 13 Our Products 20 Our Communities 23 Appendix 27 Additional definitions, supporting data and disclaimers applicable to this report can be found in Endnotes. James Hardie | Building Resilience Sustainability Repor t | FY 2025

Message from our CEO At James Hardie, sustainability is foundational to how we do business. From our manufacturing teams who are finding new ways to reduce our environmental impact to the homeowners who select our products for their durability, sustainability is a key component to fulfilling our vision of inspiring how communities design, build and grow today and tomorrow. Our commitment starts with our people, who are putting sustainability into action. Teams are reducing waste from our operations and utilizing recycled water in our plants. They’re continually evolving processes and innovating new technology with the goal of reducing the carbon dioxide (CO2) impact in our fiber cement products. By integrating our sustainability goals into our Hardie Manufacturing Operating System (HMOS), we're leveraging our culture of continuous improvement to drive action and track performance. Sustainability also goes beyond our workplace and manufacturing processes. James Hardie is creating homes that can withstand a variety of climate conditions and weather extremes. At the 2025 International Builders’ Show, we showcased new product innovations and participated in a podcast conversation with sustainability-focused builders who are utilizing our Engineered for Climate® fiber cement products. Alongside other industry leaders, we’re continuing to progress, evolve and innovate to ensure homes are built to last. “Do the Right Thing” and “Collaborate for Greatness” are two of our company’s core values. Many of our team members have demonstrated these values by volunteering to build homes wrapped in Hardie® siding for Habitat for Humanity® International over the past year. James Hardie is a proud corporate sponsor of this life-changing organization, and we look forward to continuing this inspiring work this coming year. Sustainability is a journey, and this continues with our recent acquisition of The AZEK Company Inc. in July 2025. As the industry leader in exterior home and outdoor living solutions, we have never been better positioned to explore the myriad ways we can improve our communities and our planet. As one James Hardie, we are working towards our purpose of Building a Better Future for All™. Aaron M. Erter CEO Aaron M. Erter CEO At James Hardie, our purpose is Building a Better Future for All™. Those aren't just words — we're continuing to make progress, evolve and innovate to ensure homes are built to last.” 2 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

About James Hardie James Hardie is the world’s No. 1 producer and marketer of high-performance fiber cement siding and backer board and a market leader in Europe for fiber gypsum products. James Hardie successfully uses innovation to drive market value. Our products are made from high quality and durable raw materials, delivering personalized design possibilities to consumers. We manufacture a variety of patterned profiles, surface finishes and colors for a range of applications, including siding, trim, soffit, walls, facades, floors and tile underlayment for use in residential, commercial and industrial applications. James Hardie is a public limited company incorporated, headquartered and existing under the laws of the Republic of Ireland. In the fiscal year ending 31 March 2025 (FY25), James Hardie generated approximately $3.9 billion in net sales. During the period covered by this report, James Hardie employed a global workforce of approximately 5,800 employees across operations in North America, Europe, Australia, New Zealand and the Philippines that included 19 manufacturing facilities and three research and development centers. We have since closed our Philippines manufacturing and commercial operations. As of 01 July 2025, James Hardie has acquired The AZEK Company Inc. Data in this report include all sites under James Hardie’s operational control during FY25 (except where noted). Future reports will include performance data from the consolidated company. More information on AZEK's sustainability journey is available on James Hardie’s website. Purpose Building a Better Future for All™ Vision To inspire how communities design, build and grow today and tomorrow. Mission Be the most respected and desired building materials brand in the world. Our values guide our behavior as we work to achieve our purpose. STARTS & ENDS WITH THE CUSTOMER HONOR OUR COMMITMENTS COLL ABOR ATE FOR GRE ATNESS BE BOLD AND PROGRESSIVE DO THE R IGHT THING EMBR ACE OUR DIVERSIT Y 3 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

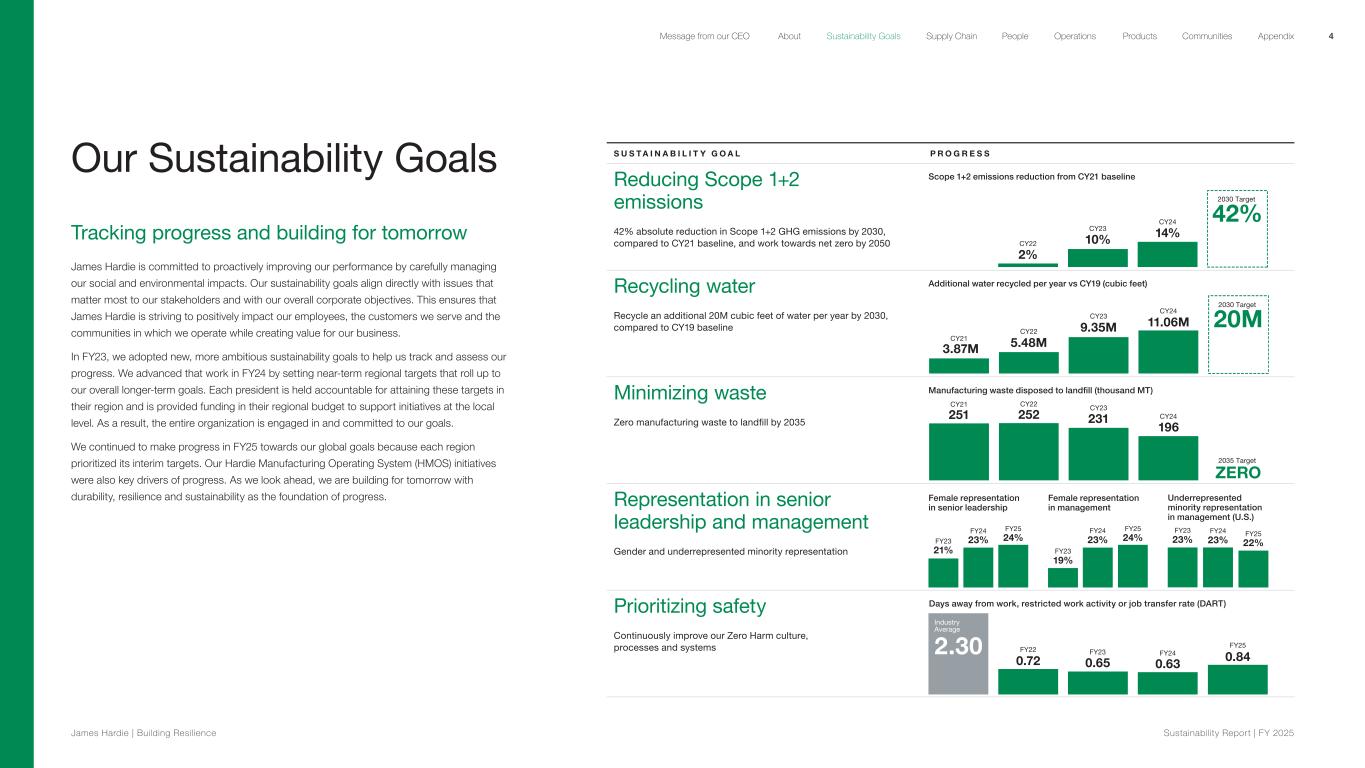

Our Sustainability Goals Tracking progress and building for tomorrow James Hardie is committed to proactively improving our performance by carefully managing our social and environmental impacts. Our sustainability goals align directly with issues that matter most to our stakeholders and with our overall corporate objectives. This ensures that James Hardie is striving to positively impact our employees, the customers we serve and the communities in which we operate while creating value for our business. In FY23, we adopted new, more ambitious sustainability goals to help us track and assess our progress. We advanced that work in FY24 by setting near-term regional targets that roll up to our overall longer-term goals. Each president is held accountable for attaining these targets in their region and is provided funding in their regional budget to support initiatives at the local level. As a result, the entire organization is engaged in and committed to our goals. We continued to make progress in FY25 towards our global goals because each region prioritized its interim targets. Our Hardie Manufacturing Operating System (HMOS) initiatives were also key drivers of progress. As we look ahead, we are building for tomorrow with durability, resilience and sustainability as the foundation of progress. S U S T A I N A B I L I T Y G O A L P R O G R E S S Reducing Scope 1+2 emissions 42% absolute reduction in Scope 1+2 GHG emissions by 2030, compared to CY21 baseline, and work towards net zero by 2050 Recycling water Recycle an additional 20M cubic feet of water per year by 2030, compared to CY19 baseline Minimizing waste Zero manufacturing waste to landfill by 2035 Representation in senior leadership and management Gender and underrepresented minority representation Prioritizing safety Continuously improve our Zero Harm culture, processes and systems 4 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix 2030 Target 42% Scope 1+2 emissions reduction from CY21 baseline 14% CY24 10% CY23 2% CY22 2030 Target 20M Additional water recycled per year vs CY19 (cubic feet) CY24 11.06M CY23 9.35MCY22 5.48MCY21 3.87M 2035 Target ZERO Manufacturing waste disposed to landfill (thousand MT) CY24 196 CY23 231252 CY22 251 CY21 Underrepresented minority representation in management (U.S.) FY25 22% FY24 23% FY23 23% Female representation in management FY25 24% FY24 23% FY23 19% Female representation in senior leadership FY25 24% FY24 23%FY23 21% Industry Average 2.30 Days away from work, restricted work activity or job transfer rate (DART) FY25 0.84FY24 0.63 FY23 0.65 FY22 0.72

Our Supply Chain Developing a more circular supply chain James Hardie is committed to developing a more circular supply chain to reduce our impact on the environment and on local landfills while strengthening our business. By increasing the use of recycled materials in our production processes and keeping manufacturing waste out of landfills, we are transitioning to a more sustainable supply chain that will allow us to produce high quality fiber cement and fiber gypsum products for decades to come. At the same time, we are reducing current and future landfill costs for our business and doing the right thing for our communities and the environment, making this a win-win strategy. We continually strive to maintain an efficient supply chain and locate our plants near our customers, benefiting our suppliers, our customers and our bottom line while reducing the impact on the environment. Our fiber cement products We continue to reduce waste by making our operations more efficient by employing our Hardie Manufacturing Operating System (HMOS), LEAN thinking and best practices across facilities. We are finding new ways to reuse materials within our plants. For example, we are increasing sludge reclamation across our operations and collaborating with local suppliers who can put some leftover materials to beneficial reuse. Efforts to reduce waste and create a circular supply chain for our fiber cement products are growing at our North America plants. Our procurement team is embracing the opportunity to reduce fiber cement discarded materials while delivering value to the business. These initiatives delivered $2 million in savings and diverted over 11% of manufacturing discarded materials from local landfills in FY25. In APAC, we eliminated 98% of the discarded materials going to landfills. Some material is recycled back into our production processes or sent to local companies to keep materials in the value stream. Our fiber gypsum products Our fermacell® fiber gypsum boards were developed as a circular product — using industrial by-product gypsum and recycled paper product — and are fully recyclable into new boards within our own production process. We adapted our processes and made a significant investment in new equipment at our Siglingen, Germany, plant to enable the use of more diverse recycled paper input streams in our fiber gypsum board production. Our fermacell® products also use recycled gypsum, which is gypsum material that has been recovered from waste drywall and other construction materials, rather than being mined as a raw material. This process diverts waste from landfills and provides an additional, sustainable source of gypsum for our products. 5 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

81% of raw materials sourced within 150 miles of our manufacturing facilities Sourcing responsibly and respecting human rights The responsible procurement of materials and services is important for James Hardie as we work to reduce our environmental and social impacts while strengthening our supply chain. We are continuing to enhance the governance of human rights issues across our value chain by maturing our understanding of potential impacts and opportunities. In FY25, we completed our first formal human rights salient issues review. Working with a third-party consultant, we engaged with internal and external stakeholders, reviewed our business operations and industry context and assessed our policies and processes to identify the issues where we have the greatest impact on people across our value chain. We emerged with a list of prioritized human rights areas for us to stay focused on, including where we're currently mitigating risks and where there are opportunities. This information will allow us to enhance our human rights due diligence program, enabling more focused collaboration externally with suppliers and business partners, and internally across the organization — ultimately strengthening our company’s accountability and preparedness. Last year, we risk mapped 100% of our in-scope Tier 1 suppliers around the globe to provide greater transparency into our supply chain and enhance our understanding of the potential risks of human and labor rights violations, including modern slavery. The results identified approximately 99% of spend of those suppliers as operating in low- to moderate-risk environments. In FY25, using a third-party service, we initiated onsite social compliance audits of the few Tier 1 suppliers identified as operating in high-risk environments. We will continue to make our supply chain even more resilient by taking steps to reduce risks through enhanced due diligence in the coming year. $1.65B in economic value* contributed in communities where we operate * We contribute to local economies through capital expenditure at our plants and by investing significantly in our employees, in local ecosystems and across our supplier base. Our direct spending through the purchase of local materials, payroll and taxes, and our local distribution network makes a positive economic impact that benefits both local economies and our customers. 6 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

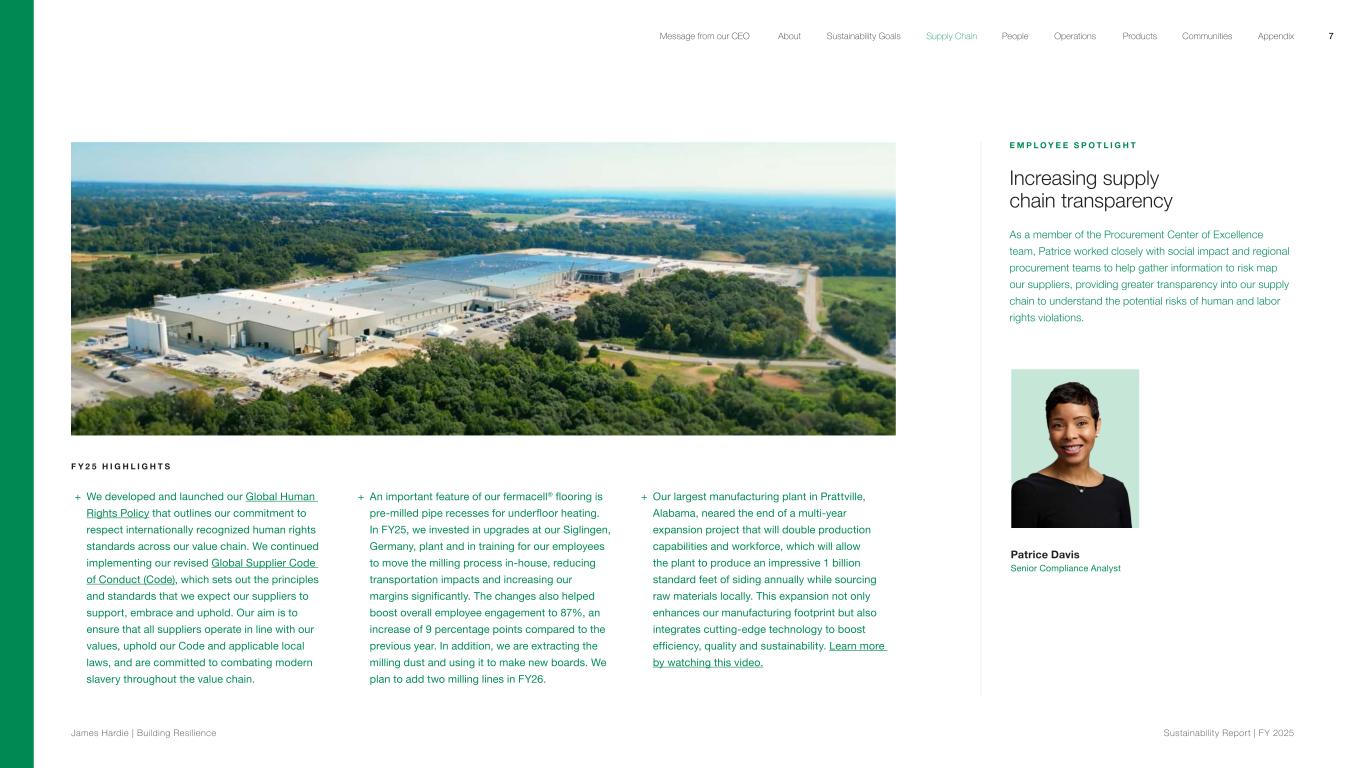

E M P L O Y E E S P O T L I G H T Increasing supply chain transparency As a member of the Procurement Center of Excellence team, Patrice worked closely with social impact and regional procurement teams to help gather information to risk map our suppliers, providing greater transparency into our supply chain to understand the potential risks of human and labor rights violations. Patrice Davis Senior Compliance Analyst F Y 2 5 H I G H L I G H T S + We developed and launched our Global Human Rights Policy that outlines our commitment to respect internationally recognized human rights standards across our value chain. We continued implementing our revised Global Supplier Code of Conduct (Code), which sets out the principles and standards that we expect our suppliers to support, embrace and uphold. Our aim is to ensure that all suppliers operate in line with our values, uphold our Code and applicable local laws, and are committed to combating modern slavery throughout the value chain. + An important feature of our fermacell® flooring is pre-milled pipe recesses for underfloor heating. In FY25, we invested in upgrades at our Siglingen, Germany, plant and in training for our employees to move the milling process in-house, reducing transportation impacts and increasing our margins significantly. The changes also helped boost overall employee engagement to 87%, an increase of 9 percentage points compared to the previous year. In addition, we are extracting the milling dust and using it to make new boards. We plan to add two milling lines in FY26. + Our largest manufacturing plant in Prattville, Alabama, neared the end of a multi-year expansion project that will double production capabilities and workforce, which will allow the plant to produce an impressive 1 billion standard feet of siding annually while sourcing raw materials locally. This expansion not only enhances our manufacturing footprint but also integrates cutting-edge technology to boost efficiency, quality and sustainability. Learn more by watching this video. 7 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Our People Investing in our strongest assets We are committed to providing a best-in-class work environment for our strongest assets — our people and teams around the world. Our culture promotes inclusion, innovation, performance and growth. In FY25, we continued to grow our People Strategy, which is comprised of three pillars: building and retaining a robust talent pool, expanding technical and leadership capabilities, and inspiring and engaging employees to enable their best selves. 93% of employees hired from local communities in which we operate Growing our learning culture We believe in investing in our employees to help them develop satisfying careers at James Hardie. Grow@Hardie brings our purpose of Building a Better Future For All™ to life by empowering our employees to drive their careers and build a better future for themselves. Building off the successes and lessons learned from the program’s inaugural year in FY24, Grow@Hardie continued its mission to engage employees through growth and career development opportunities year-round. We held our first Employee Development Month in September with virtual and in-house programs led by expert instructors. The learning and professional development opportunities focused on individual development planning, career growth strategies, skills development and more. Employees also participated in regional Core Development Days hosted at all our offices and plants around the world. Events included keynote addresses by renowned guest speakers, presentations and panel discussions with senior leadership, breakout sessions and networking opportunities. In FY25, we invested in a new leadership training program in Europe, where all 150 leaders were expected to complete an extensive four-day course to improve their skills. This program is built on lessons learned by our APAC team, who developed a similar training for their leaders. Meanwhile, we continue to invest in other training initiatives and build organizational capabilities across our workforce by expanding our talent development team, creating individual development plans for our employees and taking a more holistic approach. Our James Hardie University Online offers a variety of training opportunities to employees. By helping our employees continue to grow and reach their potential, we build a more stable and resilient workforce. 8 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Building a stronger workforce Well-being is valued and integrated into every aspect of our business, empowering our people to thrive inside and outside of James Hardie. BuildWell cultivates a culture of well-being, where employees are supported with education, resources and opportunities for their physical, mental, social and financial well-being. BuildWell is tailored to the specific needs of employees in different regions. For example, under our BuildStability pillar, we are rolling out a stock purchase program and a pension program for all our European employees that includes an employer match. As part of our BuildMindfulness and BuildStrength pillars, we now provide free professional physiotherapist and psychiatrist services onsite at our plants in Australia. In Europe, we began offering supplemental health insurance that allows our employees to access private coverage in addition to public health care and gives them full dental coverage. This new benefit is helping our employees get the quality health care they need when they need it. By having the ability to see a private provider, they can be treated more quickly and hopefully return to work sooner. BuildMindfulness: building emotional well-being 2 Our new holistic BuildWell strategy is founded on four pillars: 1 BuildStrength: building physical well-being3 BuildStability: building financial well-being 4 BuildConnections: building social well-being F Y 2 5 H I G H L I G H T S + We created Rise@Hardie, a 12-week formal internship program. This year, 41 interns participated and were provided with meaningful assignments, professional development and mentorship to enable a smooth transition to their professional careers. Our interns represent a promising talent pool for future employment at James Hardie. + We encourage healthy lifestyle behaviors by offering comprehensive, regionally tailored compensation packages that include benefits and incentives to address physical, mental and financial well-being. In FY25, we expanded our wellness tools and resources, guided by the results of a global well-being survey. + The Financial Review BOSS Best Places to Work list ranked James Hardie Australia the No. 2 Best Place to Work in the Manufacturing, Consumer Goods and Utilities Category in 2025. The award recognizes organizations that are pioneering new ways of working and pushing boundaries when it comes to workplace policies and practices. James Hardie was also named one of the World’s Best Companies of 2024 by TIME and Statista. This list recognizes the top 1,000 companies who are changing the world. 9 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

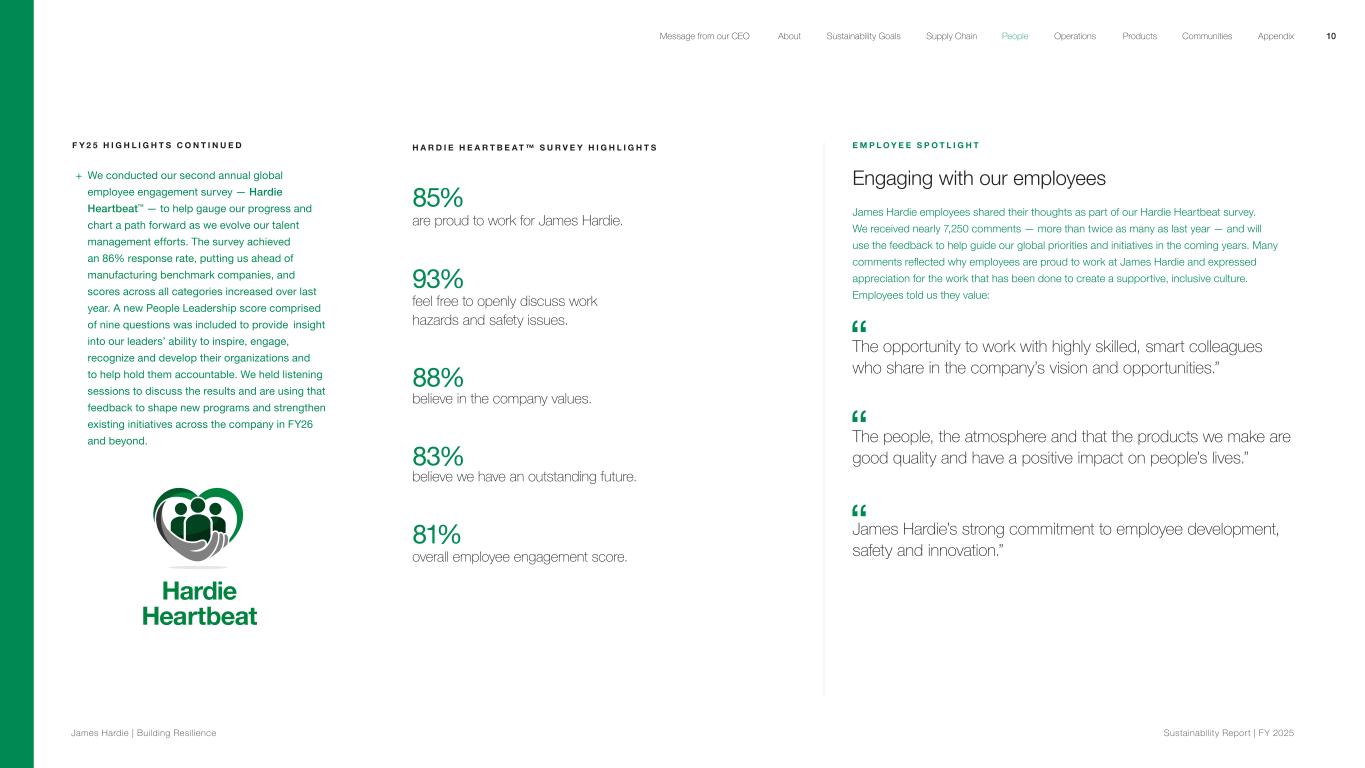

F Y 2 5 H I G H L I G H T S C O N T I N U E D + We conducted our second annual global employee engagement survey — Hardie Heartbeat™ — to help gauge our progress and chart a path forward as we evolve our talent management efforts. The survey achieved an 86% response rate, putting us ahead of manufacturing benchmark companies, and scores across all categories increased over last year. A new People Leadership score comprised of nine questions was included to provide insight into our leaders’ ability to inspire, engage, recognize and develop their organizations and to help hold them accountable. We held listening sessions to discuss the results and are using that feedback to shape new programs and strengthen existing initiatives across the company in FY26 and beyond. H A R D I E H E A R T B E A T ™ S U R V E Y H I G H L I G H T S overall employee engagement score. 85% are proud to work for James Hardie. 93% feel free to openly discuss work hazards and safety issues. 88% believe in the company values. 83% believe we have an outstanding future. 81% E M P L O Y E E S P O T L I G H T Engaging with our employees James Hardie employees shared their thoughts as part of our Hardie Heartbeat survey. We received nearly 7,250 comments — more than twice as many as last year — and will use the feedback to help guide our global priorities and initiatives in the coming years. Many comments reflected why employees are proud to work at James Hardie and expressed appreciation for the work that has been done to create a supportive, inclusive culture. Employees told us they value: The opportunity to work with highly skilled, smart colleagues who share in the company’s vision and opportunities.” The people, the atmosphere and that the products we make are good quality and have a positive impact on people’s lives.” James Hardie’s strong commitment to employee development, safety and innovation.” 10 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Belonging Inclusion and belonging are foundational to our culture and our business. We aim to ensure employees feel welcome and are able to do their best work. When we bring together people from different backgrounds, we strengthen our teams and generate value for our business. We have adopted a more strategic approach to hiring, leveraging technology and elevating the candidate experience to attract the best talent. We are also launching new initiatives in North America to increase the pipeline of qualified candidates. In addition, we are expanding engagement with universities and professional organizations such as the Society of Women Engineers and focusing on recruiting early career hires who can become candidates for higher-level positions. By revising job descriptions to be more attractive to a broader population and streamlining our applicant review process, we have reduced the time it takes to fill positions in North America. Our recruitment, HR and learning and development teams collaborate to optimize hiring, onboarding and ongoing employee development at all levels. F Y 2 5 H I G H L I G H T S + The James Hardie Engineering Development Program (EDP) is instrumental in attracting recent graduates to engineering positions at our manufacturing facilities. This full-time, rotational program is a gateway for professional growth and hands-on learning with extensive training that ranges from working with crew members on the manufacturing floor to connecting with fellow engineers across the network. Collaboration is at the heart of the EDP, allowing participants to build lasting relationships and share insights and solutions to drive continuous improvement across different plants. The program is also an important opportunity for us to build a more inclusive workforce. + In Europe, we launched training to help build cultural awareness among our employees. This program aids in creating more equitable hiring and performance processes to support our workplace goals. + We celebrated International Women’s Day across our global operations. For example, APAC held a facilitated discussion between James Hardie women employees and the Parramatta Eels Women’s rugby team. Panelists shared their career journeys in both sporting and corporate settings, highlighting barriers they had broken through and how their organizations had supported them in achieving success. 11 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Promoting a winning culture Our Employee Resource Groups (ERGs) provide specialized programs that increase cultural awareness, engagement and retention. Members have the opportunity to develop professionally, expand their networks and make an impact within their external and internal James Hardie communities. Our ERGs are initiated and led by employees, sponsored by an executive champion and, consistent with our inclusive culture, open to all employees at the company. As our ERGs mature, their influence on our business and operations is growing. They can move quickly on initiatives and have become catalysts for positive change. We are encouraging involvement in ERGs at the plant level and have completed Gemba visits to see how we can best bring ERGs to our frontline employees. Gemba, which is embedded in our Hardie Operating System (HOS), refers to going to “the real place” to get real knowledge to solve a problem. By asking questions and talking to people on the ground, we are learning what their needs are and using those insights to shape a more inclusive, supportive culture. F Y 2 5 H I G H L I G H T S + In May, our AMIGOS ERG group hosted a cultural celebration at our Cleburne, Texas, manufacturing facility that was attended by over 300 employees. Participants enjoyed a range of activities, including ERG leadership panel discussions, a plant tour and a mariachi band performance. The AMIGOS team engaged with guests on the details of ERGs and well-being benefits at James Hardie, all while celebrating the local Cleburne community and the Cinco de Mayo holiday. + In honor of Women’s History Month and International Women’s Day, James Hardie and the North America chapter of the Women’s Initiative Network (WIN) ERG presented a special speaker series, “Breaking Barriers,” featuring Nicole Malachowski. Nicole is the first woman Thunderbird pilot, combat veteran, fighter squadron commander and White House Fellow & Advisor. She provided her valuable insights on leadership, resilience and the power of perseverance to our employees. + All of our AMIGOS events, including collaborations with other ERGs, source from local businesses. We also promote local businesses at our events. + Our ASPAN ERG piloted two grassroots learning and development efforts that grew out of members identifying opportunities for growth: one for public speaking and another for mentoring. + For Women’s Health Week, the APAC WIN Network group organized a week of physical, mental and financial health activities for staff and also supported the Share the Dignity charity, which supports women who are experiencing or at risk of homelessness, domestic violence or poverty. 12 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Our Operations Integrating sustainability throughout our processes Sustainability is a foundational imperative for James Hardie, and we are integrating it throughout all aspects of our business. One key element is the integration of sustainability goals into HMOS, which helps us execute at all levels of our operations. HMOS encompasses our culture of continuous improvement and LEAN manufacturing and empowers our people to champion improvements to environmental performance. While some goals are a challenge to achieve, our teams remain focused and driven. We continue to innovate and find ways to make an impact. Our HMOS process guides the implementation of new initiatives and helps us to operationalize sustainability goals. For example, we pilot new technology solutions, such as water treatment processes, at one plant and then use what we learn to expand to other locations. In Europe, we leverage HMOS by integrating energy efficiency and intensity tracking updates for our plants into daily discussions. F Y 2 5 H I G H L I G H T S + As we studied ways to achieve a closed loop water system at our plants throughout Europe, we analyzed how much water is emitted in the exhaust systems. We assessed potential solutions and developed a plan that will allow us to eliminate that water loss. The plan also aligns with our decarbonization strategies, which include newer technology solutions designed to reduce emissions and improve efficiency. + Innovation Councils in each global region foster cross- functional collaboration and leadership accountability. We continue to invest in research and development (R&D) efforts which support product development and operational and process improvements. E M P L O Y E E S P O T L I G H T Recycling process waste for reuse in fiber cement production Our cross-functional RTY (rolled throughput yield) Improvement Team in Rosehill, Australia, developed and implemented technology to recycle dust created during the low-density additive process back into our fiber cement manufacturing. This process eliminates the equivalent of 200 metric tons of dust per year from landfill and saves an estimated AU$80,000 a year in waste costs. Ishita Puri Research Scientist, R&D John Garrard Quality Manager Lindsay Hill Raw Materials & Product Support Lead, R&D Mayank Bhardwaj Raw Materials Engineer, Manufacturing 13 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

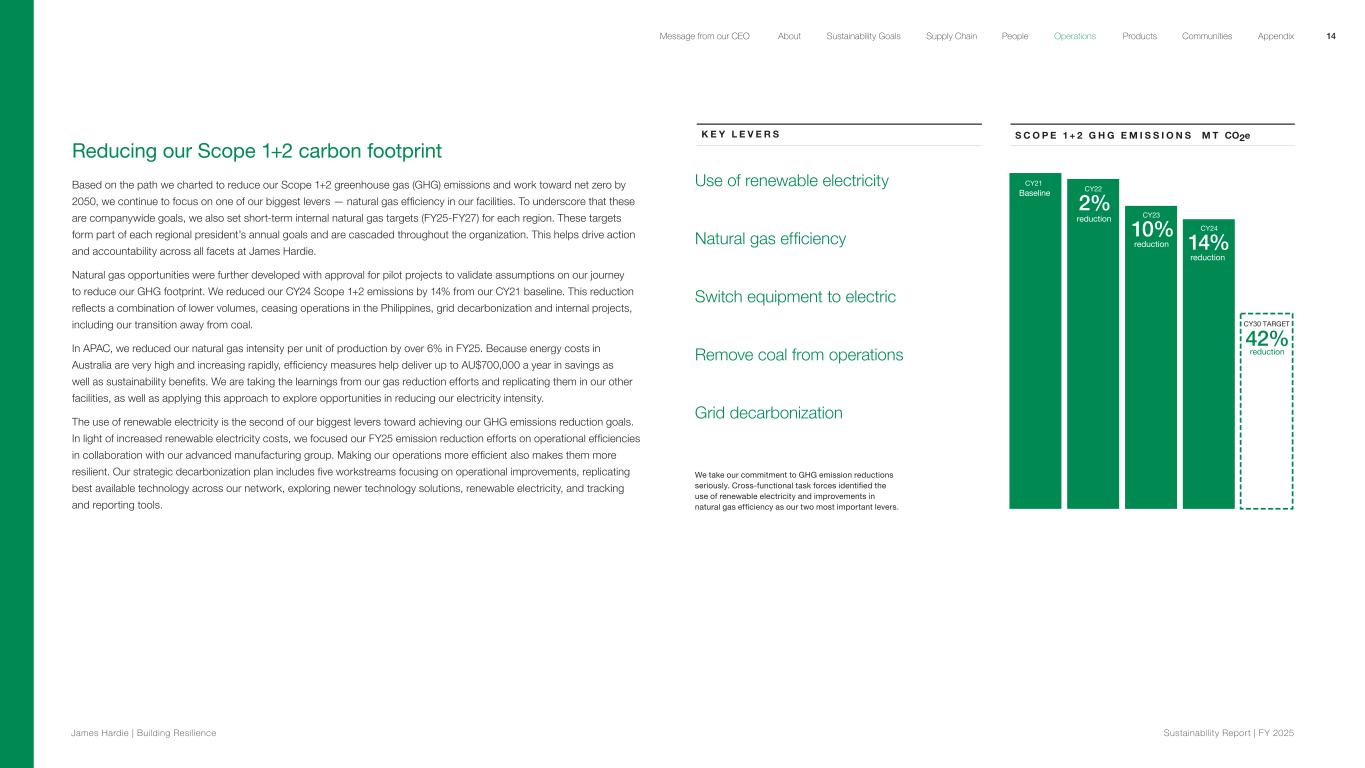

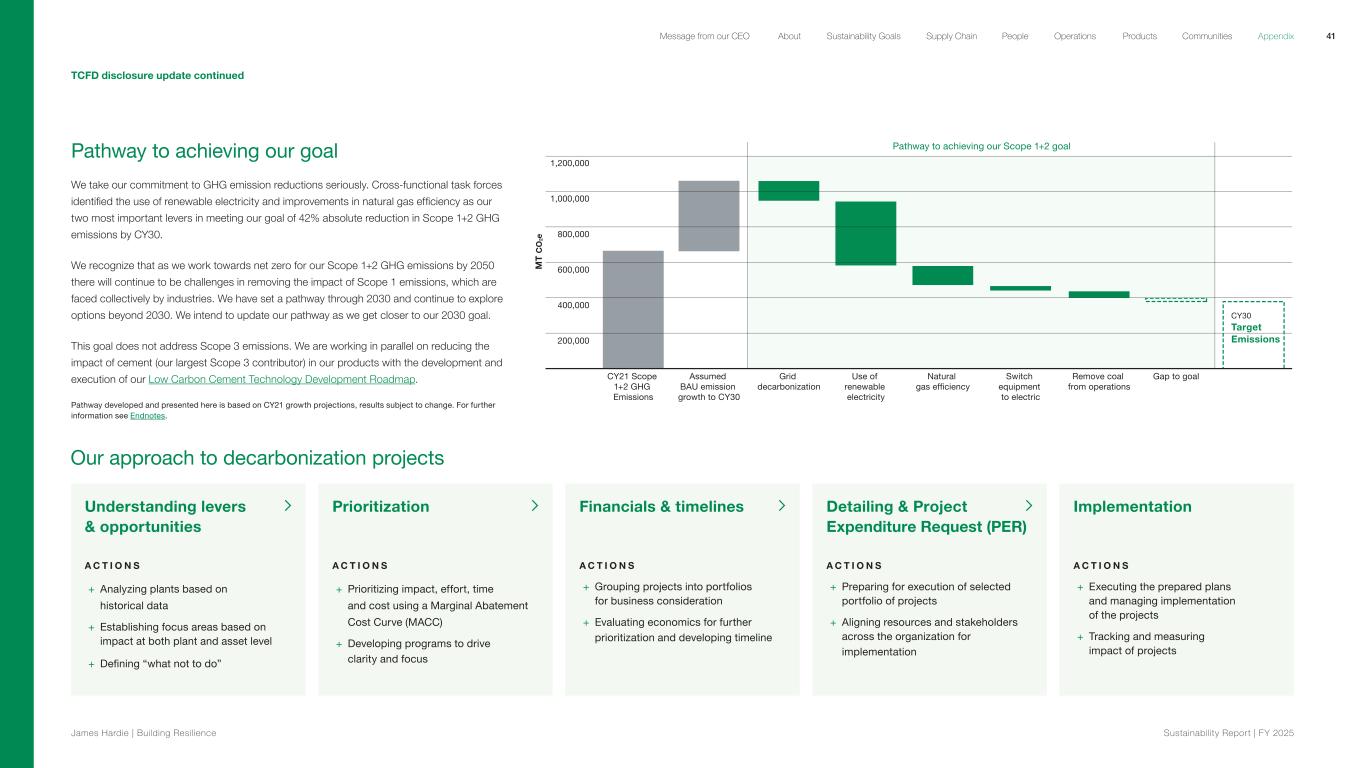

Reducing our Scope 1+2 carbon footprint Based on the path we charted to reduce our Scope 1+2 greenhouse gas (GHG) emissions and work toward net zero by 2050, we continue to focus on one of our biggest levers — natural gas efficiency in our facilities. To underscore that these are companywide goals, we also set short-term internal natural gas targets (FY25-FY27) for each region. These targets form part of each regional president’s annual goals and are cascaded throughout the organization. This helps drive action and accountability across all facets at James Hardie. Natural gas opportunities were further developed with approval for pilot projects to validate assumptions on our journey to reduce our GHG footprint. We reduced our CY24 Scope 1+2 emissions by 14% from our CY21 baseline. This reduction reflects a combination of lower volumes, ceasing operations in the Philippines, grid decarbonization and internal projects, including our transition away from coal. In APAC, we reduced our natural gas intensity per unit of production by over 6% in FY25. Because energy costs in Australia are very high and increasing rapidly, efficiency measures help deliver up to AU$700,000 a year in savings as well as sustainability benefits. We are taking the learnings from our gas reduction efforts and replicating them in our other facilities, as well as applying this approach to explore opportunities in reducing our electricity intensity. The use of renewable electricity is the second of our biggest levers toward achieving our GHG emissions reduction goals. In light of increased renewable electricity costs, we focused our FY25 emission reduction efforts on operational efficiencies in collaboration with our advanced manufacturing group. Making our operations more efficient also makes them more resilient. Our strategic decarbonization plan includes five workstreams focusing on operational improvements, replicating best available technology across our network, exploring newer technology solutions, renewable electricity, and tracking and reporting tools. K E Y L E V E R S S C O P E 1 + 2 G H G E M I S S I O N S M T CO2e CY30 TARGET 42% reduction CY23 10% reduction reduction CY24 14% CY22 CY21 2% reduction Baseline Use of renewable electricity Natural gas efficiency Switch equipment to electric Remove coal from operations Grid decarbonization We take our commitment to GHG emission reductions seriously. Cross-functional task forces identified the use of renewable electricity and improvements in natural gas efficiency as our two most important levers. 14 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

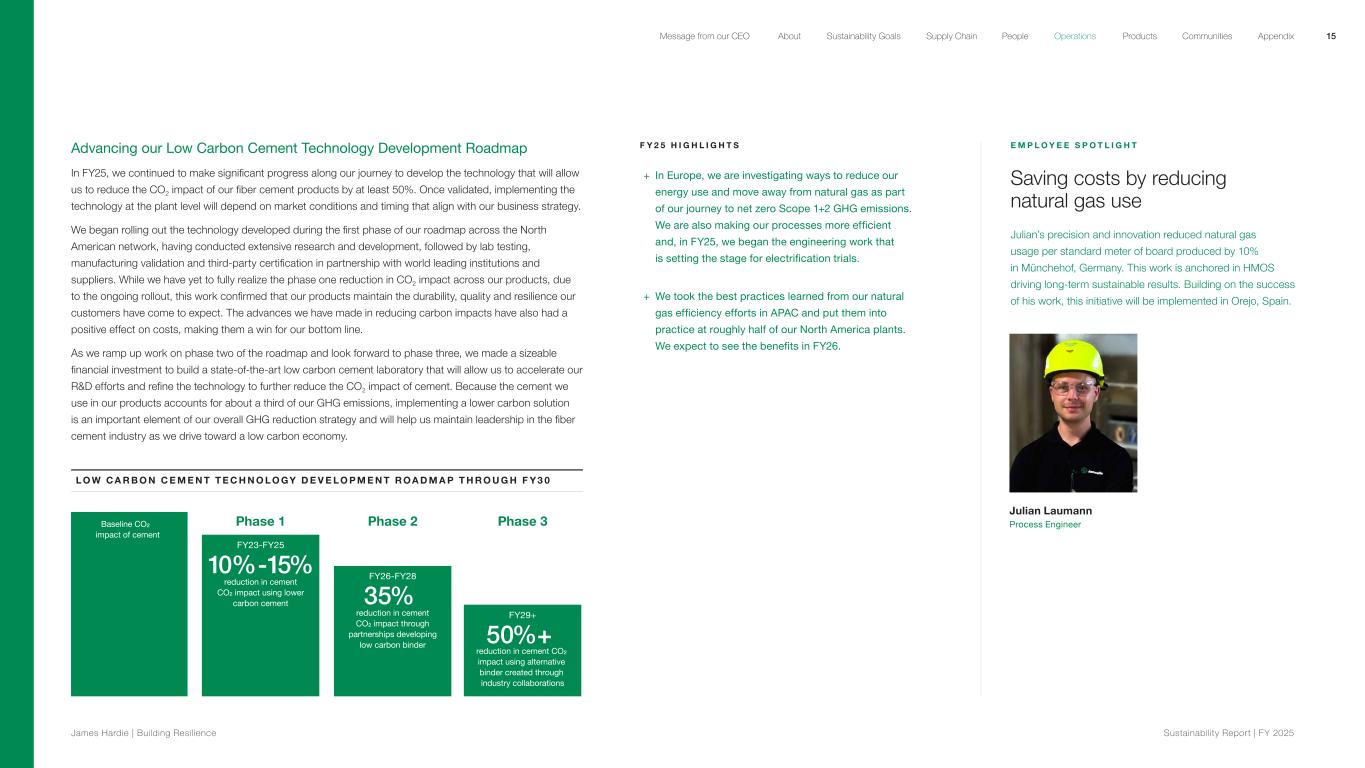

Advancing our Low Carbon Cement Technology Development Roadmap In FY25, we continued to make significant progress along our journey to develop the technology that will allow us to reduce the CO2 impact of our fiber cement products by at least 50%. Once validated, implementing the technology at the plant level will depend on market conditions and timing that align with our business strategy. We began rolling out the technology developed during the first phase of our roadmap across the North American network, having conducted extensive research and development, followed by lab testing, manufacturing validation and third-party certification in partnership with world leading institutions and suppliers. While we have yet to fully realize the phase one reduction in CO2 impact across our products, due to the ongoing rollout, this work confirmed that our products maintain the durability, quality and resilience our customers have come to expect. The advances we have made in reducing carbon impacts have also had a positive effect on costs, making them a win for our bottom line. As we ramp up work on phase two of the roadmap and look forward to phase three, we made a sizeable financial investment to build a state-of-the-art low carbon cement laboratory that will allow us to accelerate our R&D efforts and refine the technology to further reduce the CO2 impact of cement. Because the cement we use in our products accounts for about a third of our GHG emissions, implementing a lower carbon solution is an important element of our overall GHG reduction strategy and will help us maintain leadership in the fiber cement industry as we drive toward a low carbon economy. L O W C A R B O N C E M E N T T E C H N O L O GY D E V E L O P M E N T R O A D M A P T H R O U G H F Y 3 0 F Y 2 5 H I G H L I G H T S + In Europe, we are investigating ways to reduce our energy use and move away from natural gas as part of our journey to net zero Scope 1+2 GHG emissions. We are also making our processes more efficient and, in FY25, we began the engineering work that is setting the stage for electrification trials. + We took the best practices learned from our natural gas efficiency efforts in APAC and put them into practice at roughly half of our North America plants. We expect to see the benefits in FY26. E M P L O Y E E S P O T L I G H T Saving costs by reducing natural gas use Julian’s precision and innovation reduced natural gas usage per standard meter of board produced by 10% in Münchehof, Germany. This work is anchored in HMOS driving long-term sustainable results. Building on the success of his work, this initiative will be implemented in Orejo, Spain. Julian Laumann Process Engineer Baseline CO² impact of cement 10%-15% reduction in cement CO² impact using lower carbon cement FY23-FY25 Phase 1 FY26-FY28 35% reduction in cement CO² impact through partnerships developing low carbon binder Phase 2 FY29+ 50%+ reduction in cement CO² impact using alternative binder created through industry collaborations Phase 3 15 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Reducing waste for a more resilient planet and business Reducing — and ultimately eliminating — the waste generated by our manufacturing operations is a responsibility James Hardie takes seriously. We continue to develop new ways to recycle materials and resources within our plants. We also collaborate with companies throughout our supply chain to keep potential waste materials in the value stream and partner with local suppliers who can put some of the leftover materials from our operations to beneficial reuse. Finding beneficial uses for the materials left over from our operations is also a key driver toward achieving our goal of zero manufacturing waste to landfill by 2035. These efforts not only help to reduce our impact on the environment and on local landfills but also strengthen our business. In North America, we secured permits to send reject boards from several locations to local cement manufacturers. In Australia, we continue to work with concrete supplier Boral, which has a net-zero goal, to reuse waste from our plants in its manufacturing process. In FY25, we identified beneficial reuse applications for the waste from our Calbe, Germany, plant where we produce cement bonded boards for niche applications such as fire protection. We invested several million dollars to set up milling equipment to crush reject materials. We will recycle a portion of the crushed material to make new boards and work with a partner for the beneficial reuse of the remainder, while we continue to work on increasing internal recycling. This effort will divert approximately 8,000 metric tons of waste a year from landfills — a significant portion of landfill waste currently generated in Europe — and creates a closed loop in our value chain because the cement that is made with the crushed materials goes back into the manufacture of our products. This is a win for the environment and our bottom line, and we will continue working to increase the amount of material we can reuse within our plants. F Y 2 5 H I G H L I G H T S + We regularly ship pallets of product from North America to Europe where it is painted in custom colors for our customers. In FY25, we developed a recycling program that allows us to reuse these costly pallets, which must meet import/export requirements. By returning the pallets to our Pulaski, Virginia, plant for reuse, we are saving $1.5 million a year. + We continue to maintain ISO 14001 certification for our environmental management systems at the corporate level and at nine of our plants globally, including all our locations throughout Europe. + We maintain ISO 50001 certification for our energy management system across four of our European plants and are in the process of rolling it out to two further facilities. E M P L O Y E E S P O T L I G H T Creating more reusable material while reducing waste Chris and the Tacoma 1 team reduced machine cone purges by 75%, resulting in more reusable material and less sludge hauls. Their innovation to automate the recirculation in the machine cone during delay events has eliminated cone purges on startups and saves the plant approximately $80,000 a year in sludge haul costs. Chris Kerr Raw Materials Engineer 16 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

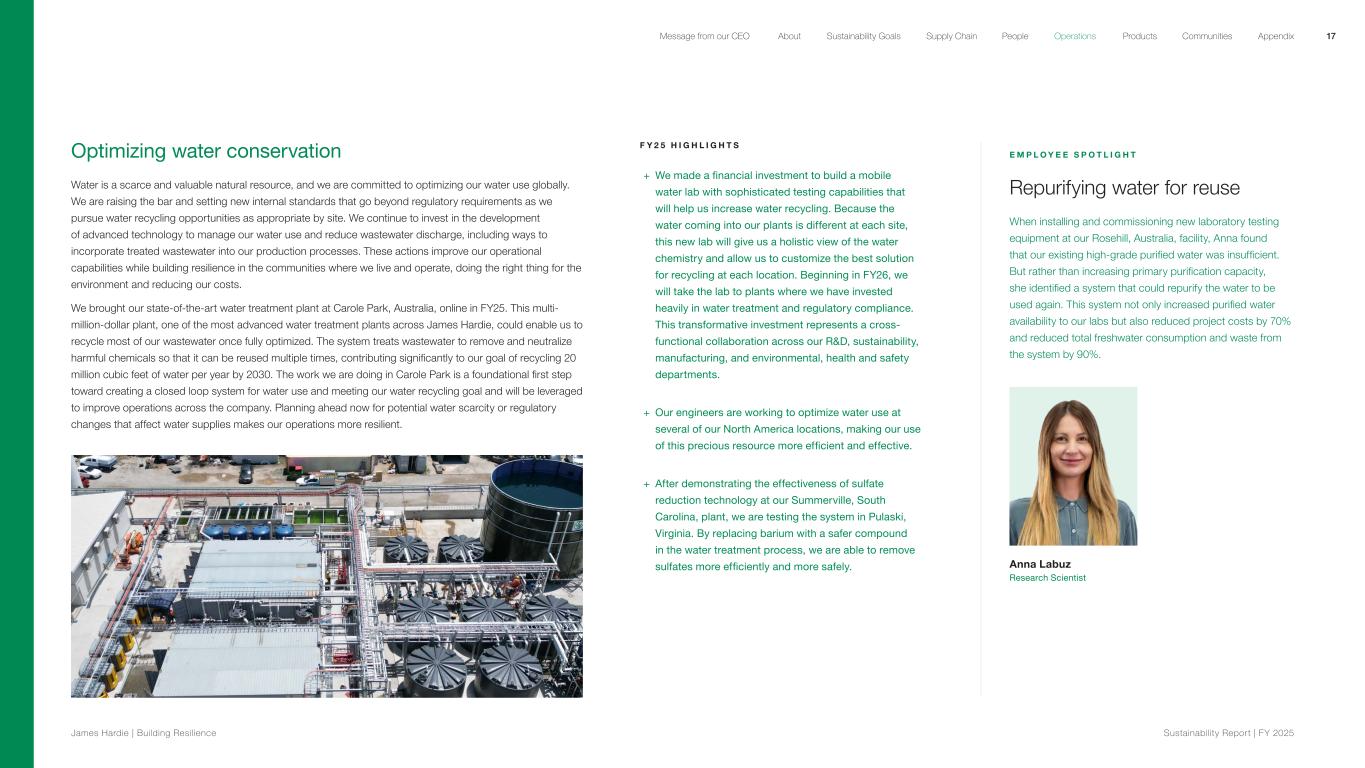

Optimizing water conservation Water is a scarce and valuable natural resource, and we are committed to optimizing our water use globally. We are raising the bar and setting new internal standards that go beyond regulatory requirements as we pursue water recycling opportunities as appropriate by site. We continue to invest in the development of advanced technology to manage our water use and reduce wastewater discharge, including ways to incorporate treated wastewater into our production processes. These actions improve our operational capabilities while building resilience in the communities where we live and operate, doing the right thing for the environment and reducing our costs. We brought our state-of-the-art water treatment plant at Carole Park, Australia, online in FY25. This multi- million-dollar plant, one of the most advanced water treatment plants across James Hardie, could enable us to recycle most of our wastewater once fully optimized. The system treats wastewater to remove and neutralize harmful chemicals so that it can be reused multiple times, contributing significantly to our goal of recycling 20 million cubic feet of water per year by 2030. The work we are doing in Carole Park is a foundational first step toward creating a closed loop system for water use and meeting our water recycling goal and will be leveraged to improve operations across the company. Planning ahead now for potential water scarcity or regulatory changes that affect water supplies makes our operations more resilient. F Y 2 5 H I G H L I G H T S + We made a financial investment to build a mobile water lab with sophisticated testing capabilities that will help us increase water recycling. Because the water coming into our plants is different at each site, this new lab will give us a holistic view of the water chemistry and allow us to customize the best solution for recycling at each location. Beginning in FY26, we will take the lab to plants where we have invested heavily in water treatment and regulatory compliance. This transformative investment represents a cross- functional collaboration across our R&D, sustainability, manufacturing, and environmental, health and safety departments. + Our engineers are working to optimize water use at several of our North America locations, making our use of this precious resource more efficient and effective. + After demonstrating the effectiveness of sulfate reduction technology at our Summerville, South Carolina, plant, we are testing the system in Pulaski, Virginia. By replacing barium with a safer compound in the water treatment process, we are able to remove sulfates more efficiently and more safely. E M P L O Y E E S P O T L I G H T Repurifying water for reuse When installing and commissioning new laboratory testing equipment at our Rosehill, Australia, facility, Anna found that our existing high-grade purified water was insufficient. But rather than increasing primary purification capacity, she identified a system that could repurify the water to be used again. This system not only increased purified water availability to our labs but also reduced project costs by 70% and reduced total freshwater consumption and waste from the system by 90%. Anna Labuz Research Scientist 17 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Prioritizing Zero Harm Safety is embedded in our global corporate culture through our Zero Harm practices and philosophy in HMOS and our commitment to continuous improvement. We consider safety everyone’s responsibility and work diligently 24/7 to ensure the protection of our people and those who use or interact with our products. We believe that every incident is preventable, and we work toward Zero Harm through a focus on safe people, safe places and safe systems. Over a three-year period, we are investing more than $75 million in strategic safety infrastructure projects globally. We are upgrading safety equipment as part of our focus on the areas of highest risk for our employees: working from heights, machine guarding and energy control processes. Our engineered solutions also include special attention to the control of hazardous energy. In FY25, we installed sophisticated engineered fall arrest systems in all our North American plants. We also have made advances in machine guarding across the region. Machine guards provide protection for our employees while promoting risk awareness. Our Tacoma, Washington, plant installed guards in the entire sheet machine area, a first for the region, and is moving on to guarding in the cutting lines. In keeping with our HMOS philosophy, we plan to apply that successful framework to other safety processes over the next three years by piloting the solution at one plant and then taking advantage of the learnings as we move on to the next location. Our APAC and Europe regions also completed machine guarding installations and upgrades to make working from heights safer; additional upgrades are planned there over the next two years. We relentlessly pursue critical risk reductions through a focused approach on global standardization of best practices. Safety standards for energy control processes, machine guarding, working from heights and electrical safety have been developed and independently approved in North America and APAC. While our overall FY25 DART rate remains well below the industry average, we acknowledge that it did increase from our FY24 rate. We are actively addressing this through increased leadership engagement, continued execution of strategic safety projects and proactive risk mitigation on the plant floor. Looking forward, we plan to work with a consultant to develop a strategic long-term environmental health, safety and security roadmap and continue to leverage our HOS to spark engagement across the company. E M P L O Y E E S P O T L I G H T Recognizing exemplary safety leadership To coincide with our Global Zero Harm Month, we presented our second annual Zero Harm CEO Awards to sites and individual employees from each region to recognize those who routinely go above and beyond when it comes to safety. Each winning site (Tacoma 2, Washington; Rosehill, Australia; and Orejo, Spain) demonstrated continuous improvement and increased engagement and consistently works to achieve established global standards in Zero Harm. Our individual winners demonstrated exemplary safety leadership and behaviors daily and are committed to the James Hardie Zero Harm philosophy. Adrian Magaldi EHS Manager Orejo, Spain Mike Dye Specialist Operator Peru, Illinois Cade Watkins Engineer Westfield, Massachusetts Nathan Anderson Operator Carole Park, Australia 18 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

+ We surveyed employees to get their feedback on this year’s Global Zero Harm Month so that we can continually improve this event. Hundreds of employees shared what safety ownership meant to them, and their responses were transformed into a graphical representation of our Zero Harm culture. Here’s a sampling of what we heard: Taking ownership of safety means taking personal responsibility for my own safety, as well as contributing to the safety of those around me. It means being aware of my (surroundings), taking proactive measures to foster a safe environment, speaking up when I am uncomfortable, and supporting others to foster a community where we all look out for one another.” It is ultimately my responsibility to make sure that I take safety seriously, as seriously I take everything else, because everything else is irrelevant if something were to happen.” I have the power to make sure that both myself and the people around me go home every day to our families just as we came to work in the morning.” F Y 2 5 H I G H L I G H T S + Our second annual Global Zero Harm Month rallied team members around our theme of “Safety Ownership Starts with Me.” Through 35 events, we brought our Zero Harm foundational imperative to life with a focus on our individual and shared accountability to maintain a safe working environment for ourselves and others. Global focus areas this year included fall protection, machine guarding, lockout tagout and mental health and wellness. Local events featured impactful keynote addresses targeted to each unique work environment in addition to a selection of 16 demonstrations all tied to critical risk and other key safety topics. 19 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

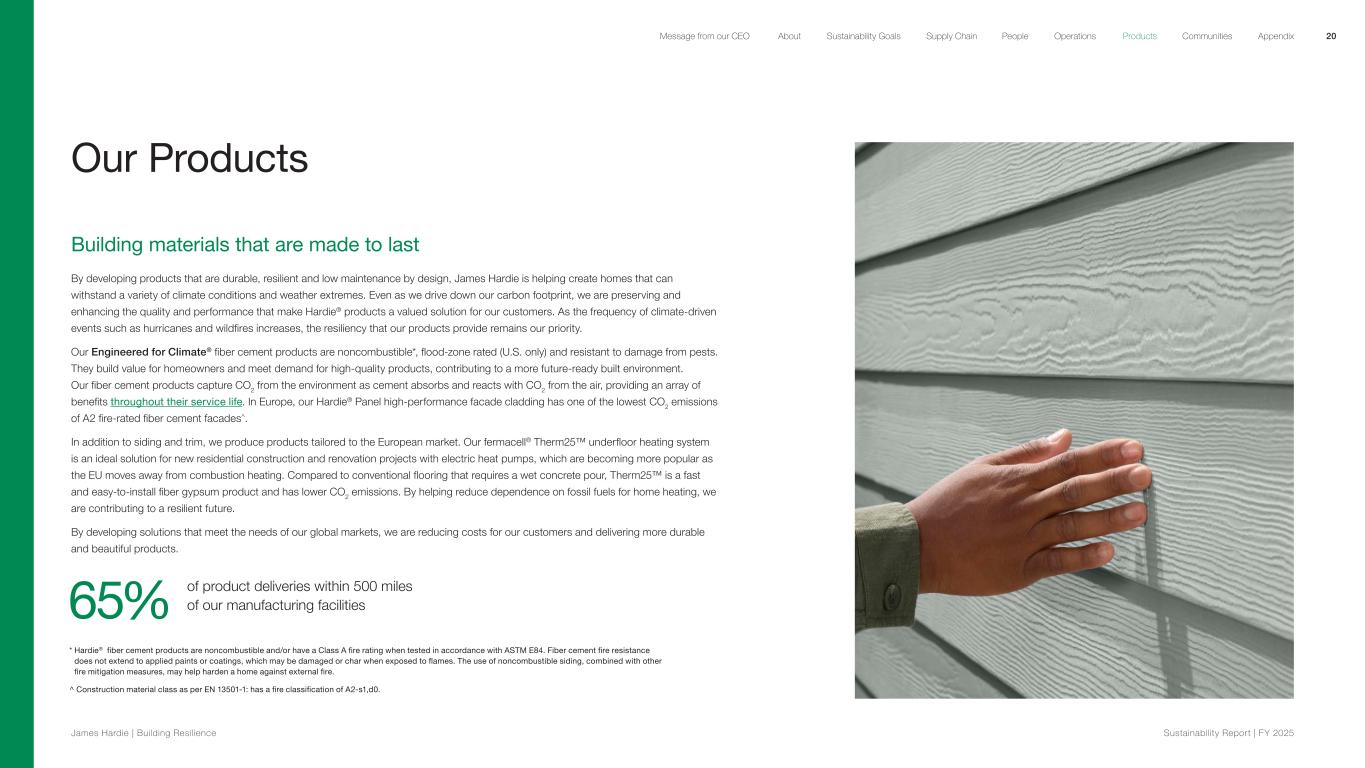

Our Products Building materials that are made to last By developing products that are durable, resilient and low maintenance by design, James Hardie is helping create homes that can withstand a variety of climate conditions and weather extremes. Even as we drive down our carbon footprint, we are preserving and enhancing the quality and performance that make Hardie® products a valued solution for our customers. As the frequency of climate-driven events such as hurricanes and wildfires increases, the resiliency that our products provide remains our priority. Our Engineered for Climate® fiber cement products are noncombustible*, flood-zone rated (U.S. only) and resistant to damage from pests. They build value for homeowners and meet demand for high-quality products, contributing to a more future-ready built environment. Our fiber cement products capture CO2 from the environment as cement absorbs and reacts with CO2 from the air, providing an array of benefits throughout their service life. In Europe, our Hardie® Panel high-performance facade cladding has one of the lowest CO2 emissions of A2 fire-rated fiber cement facades^. In addition to siding and trim, we produce products tailored to the European market. Our fermacell® Therm25™ underfloor heating system is an ideal solution for new residential construction and renovation projects with electric heat pumps, which are becoming more popular as the EU moves away from combustion heating. Compared to conventional flooring that requires a wet concrete pour, Therm25™ is a fast and easy-to-install fiber gypsum product and has lower CO2 emissions. By helping reduce dependence on fossil fuels for home heating, we are contributing to a resilient future. By developing solutions that meet the needs of our global markets, we are reducing costs for our customers and delivering more durable and beautiful products. 65% of product deliveries within 500 miles of our manufacturing facilities * Hardie® fiber cement products are noncombustible and/or have a Class A fire rating when tested in accordance with ASTM E84. Fiber cement fire resistance does not extend to applied paints or coatings, which may be damaged or char when exposed to flames. The use of noncombustible siding, combined with other fire mitigation measures, may help harden a home against external fire. ^ Construction material class as per EN 13501-1: has a fire classification of A2-s1,d0. 20 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Innovation for Building a Better Future for All™ Our Homeowner Focused, Customer and Contractor Driven™ philosophy is powered by innovation and the needs of those who use our products. We continue to develop new solutions that provide superior value to our customers and help them build better homes and more resilient communities. Our innovative approach is unlocking the potential for these benefits to be more affordable and available for homeowners across all price points. Cross-functional collaboration among our R&D, marketing, sales and products teams is driving this affordability focus across our value chain. We are combining our work with contractors and installers with our innovations, such as improvements to our Statement Collection® offer and distribution model, to materially lower the price that a homeowner pays for Hardie® siding. For example, our new Trim Over install methodology, coupled with efforts through the James Hardie™ ALLIANCE program, has led to price reductions in specific markets. We plan to expand these efforts and continue the development of our solutions to reduce on-the-wall costs to continue driving meaningful value to the market over the coming months and years. Showcasing beauty that stands the test of time James Hardie collaborates with leading architects and builders to demonstrate the modern standard of performance and beauty, while innovating to ensure our durable products can withstand a variety of climate conditions and extremes. In 2024, we worked with builders to spotlight three resilient homes in the Mountain, Midwest and Mid-Atlantic regions of the United States. In 2025, we were part of new and renovated home projects with leading architects and builders from Texas and Minnesota, in collaboration with Green Builder® Media and ProTradeCraft. In Austin, Texas, Green Builder® Media, along with Barley | Pfeiffer Architecture, is constructing the VISION House Austin. The home’s climate responsive design features Hardie® Artisan® Siding and Hardie® Artisan® Trim fiber cement products, which offer design features that set the home apart. James Hardie formulates products for specific climates with the Hardie™ Zone System that creates a substrate engineered to resist cracking, shrinking and swelling. The Austin home features our HZ10® products that offer protection from the hot, humid conditions and blistering sun in Texas. Our approach is to rely on climate-responsive design principles that include strategies that will enable this house to protect itself from the elements and look good for years to come before any maintenance is needed. To augment these strategies, we made a point to specify superior exterior cladding materials that are water-shedding as opposed to moisture absorbing, so they will continue to be durable and make for a truly sustainable home.” — Peter Pfeiffer Architect, VISION House Austin 21 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

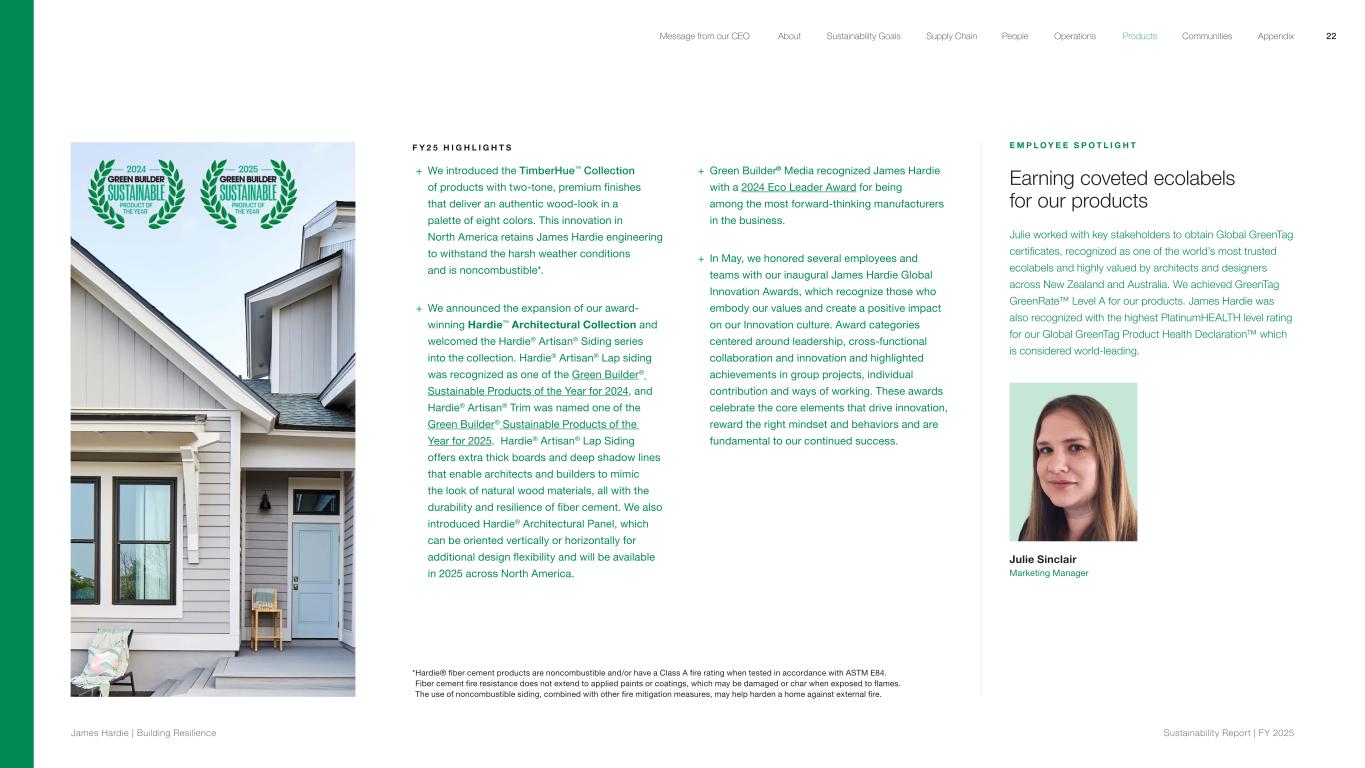

F Y 2 5 H I G H L I G H T S + We introduced the TimberHue™ Collection of products with two-tone, premium finishes that deliver an authentic wood-look in a palette of eight colors. This innovation in North America retains James Hardie engineering to withstand the harsh weather conditions and is noncombustible*. + We announced the expansion of our award- winning Hardie™ Architectural Collection and welcomed the Hardie® Artisan® Siding series into the collection. Hardie® Artisan® Lap siding was recognized as one of the Green Builder® Sustainable Products of the Year for 2024, and Hardie® Artisan® Trim was named one of the Green Builder® Sustainable Products of the Year for 2025. Hardie® Artisan® Lap Siding offers extra thick boards and deep shadow lines that enable architects and builders to mimic the look of natural wood materials, all with the durability and resilience of fiber cement. We also introduced Hardie® Architectural Panel, which can be oriented vertically or horizontally for additional design flexibility and will be available in 2025 across North America. + Green Builder® Media recognized James Hardie with a 2024 Eco Leader Award for being among the most forward-thinking manufacturers in the business. + In May, we honored several employees and teams with our inaugural James Hardie Global Innovation Awards, which recognize those who embody our values and create a positive impact on our Innovation culture. Award categories centered around leadership, cross-functional collaboration and innovation and highlighted achievements in group projects, individual contribution and ways of working. These awards celebrate the core elements that drive innovation, reward the right mindset and behaviors and are fundamental to our continued success. E M P L O Y E E S P O T L I G H T Earning coveted ecolabels for our products Julie worked with key stakeholders to obtain Global GreenTag certificates, recognized as one of the world’s most trusted ecolabels and highly valued by architects and designers across New Zealand and Australia. We achieved GreenTag GreenRate™ Level A for our products. James Hardie was also recognized with the highest PlatinumHEALTH level rating for our Global GreenTag Product Health Declaration™ which is considered world-leading. Julie Sinclair Marketing Manager *Hardie® fiber cement products are noncombustible and/or have a Class A fire rating when tested in accordance with ASTM E84. Fiber cement fire resistance does not extend to applied paints or coatings, which may be damaged or char when exposed to flames. The use of noncombustible siding, combined with other fire mitigation measures, may help harden a home against external fire. 22 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Our Communities Supporting resilient communities worldwide James Hardie’s global giving and community engagement strategy brings to life our purpose of Building a Better Future for All™ and is aligned with our business objectives. We are developing resilient building solutions that do right by our shared planet as well as support communities where our products are used and where our team of more than 5,800 global employees live and work. From our employees to our senior leaders, everyone is empowered to drive change in their communities. Our culture emphasizes thinking globally while acting locally. Our charitable giving and community engagement activities are organized into three pillars: Disaster relief When our communities are impacted by natural disasters, we work to show up with our products, time and money to rebuild in partnership with local organizations and governments. Safe, resilient, durable shelter We prioritize supporting families, and in turn our communities, in need of affordable safe housing. 1 2 3 STEM & manufacturing education We want to nurture the next generation to help build and maintain sustainable communities. 23 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Providing disaster relief to those in need When disasters big and small strike, we show up to help. We are proud to offer emergency financial donations, but our strength and the way we can offer the most value is by collaborating with local organizations to rebuild homes and other community buildings through product donations and volunteer efforts. We understand that disaster recovery is a years-long process, and we are prepared to support communities when they are ready to rebuild. H E R E A R E S O M E W A Y S W E H E L P E D I N F Y 2 5 : + After Hurricane Helene caused severe devastation across the Southeast U.S. in 2024, many communities were left without essential services, water and food. Some of our employees were among those impacted, especially in Plant City, Florida, and Summerville, South Carolina, and we worked to provide them with the appropriate support and resources to ensure their safety. To support immediate relief and recovery efforts, we provided cash donations to Team Rubicon and World Central Kitchen to assist affected communities and encouraged employees who were able to join us. + We also quickly provided financial donations to support the California Fire Benevolent Foundation and California Fire Foundation after the devastating 2025 wildfires in Los Angeles and surrounding areas. Our AMIGOS ERG spearheaded a collection drive for essential items such as diapers, toiletries and clothing to immediately help families displaced by the fires. Employees brought their donations to our Fontana, California, site, and AMIGOS leaders coordinated deliveries to donation drop off sites where they were most needed. Several Fontana employees also volunteered to help prepare freshly cooked meals at the Los Angeles Dream Center, which provided disaster relief for those affected by the fires. + Habitat for Humanity® Maui is in the process of rebuilding six homes damaged by the 2023 wildfires in the Lahaina, Hawaii, community. During the construction phase, one of the homes is being used as a bunk house to provide volunteers from around the world who come to help with a place to live. That home will be sold as affordable housing to a local family once construction is completed. Our product donations of nearly 17,000 square feet will provide exterior siding for all six homes. 24 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Collaborating with Habitat for Humanity® around the globe We have proudly supported Habitat for Humanity® International for many years as part of our efforts to fulfill our purpose of Building a Better Future for All™. We have donated siding, trim, soffit and weather barrier, and hundreds of our employees have given their time and talents to build Habitat homes. Last year, we announced our corporate sponsorship of the Habitat Strong initiative. As part of our three-year commitment, we make financial grants and donate our engineered-to-last fiber cement siding and trim products to enable the construction of homes across the United States. Learn more by watching this video. Some of the projects we supported rebuilt homes after a natural disaster struck, while others focused on fortifying homes in vulnerable areas. In FY25, 29 Habitat Strong grants were provided to build affordable and climate-resilient homes that can withstand severe weather conditions and natural disasters. We also teamed up with Habitat for Humanity® to build homes with Hardie® siding and trim in South Chicago, Illinois. Nearly 50 employees volunteered their time and talents to help construct four new 1,600-sqare-foot homes. Through Habitat Women in Australia, our employees participated in 10 volunteer days, and we donated cash and products to help teach women installation skills, building job resilience in communities. In addition, our Rosehill team volunteered with Habitat for Humanity® Australia’s bushfire resilience program to help homeowners better prepare for future disasters. Employees spent the day at a residence creating fire breaks and clearing gutters and vegetation that could be fire hazards. In New Zealand, we donated a full suite of products — including soffits, tile underlay and cladding — totaling over 17,000 square feet to Habitat for Humanity® Northern Region. The materials were used to construct a housing development in Whangarei, which provided homes for 42 families. Through Habitat for Humanity® in Europe, we donated over 50,000 square feet of product to social housing projects in Romania and rebuiliding efforts in Ukraine. 25 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

F Y 2 5 H I G H L I G H T S + The inaugural James Hardie™ Pro Football Hall of Fame Invitational golf tournament took place in spring 2025 at the Old Course at Broken Sound in Boca Raton, Florida. Charitable partners Habitat for Humanity® Greater Palm Beach County, First Tee Florida Gold Coast and Boca Raton Regional Hospital Foundation benefitted from the event. In advance of the tournament, James Hardie teamed up with members of the Pro Football Hall of Fame to help build homes for families in Ohio and Florida. + We continued our partnership and support of First Tee® in the United States. First Tee is a youth development organization seamlessly integrating the game of golf with a life skills curriculum that helps to foster resilience and strong character. 600K+ square feet of material donated by James Hardie to support our local communities in FY25, in addition to monetary contributions E M P L O Y E E S P O T L I G H T Coordinating donations for good Lupe leads many of the donation and charitable activities conducted by our R&D department in Fontana, California. She ensures pallets of material from R&D projects which cannot be sold, but meet quality standards, are instead donated to Habitat for Humanity® ReStore. Lupe also coordinates a volunteer day to support Homes for Our Troops, a nonprofit that builds adapted custom homes for severely injured veterans. Lupe Olive Team Leader, Research and Product Development + Locally, our employees get involved with charitable organizations and support projects that are personally meaningful to them. Employee-led efforts included: — Our Australia offices hosted their annual Christmas charity drive which benefits different charitable organizations each year. In FY25, nearly AU$18,000 was raised, matched dollar-for-dollar by James Hardie and then donated evenly between two charities: Habitat for Humanity® Australia and Disaster Relief Australia. — APAC employees Shannen Banfield and Alexis Pieterse arranged a volunteer event with OzHarvest for more than 60 attendees of our Asia Pacific Leadership Forum. With support from chefs, the team used rescued food which might otherwise have gone to waste to prepare fresh and nutritious meals for people in need. — James Hardie is proud to return as the major sponsor of the Parramatta Eels National Rugby League Club in Western Sydney, Australia. We are also collaborating with the Parramatta Eels to encourage young people to consider a career in construction and empower them through learning and development opportunities. As part of this initiative, our installation and construction managers were on site at Productivity Bootcamp’s Penrith Campus in March to train instructors for a three-day cladding intensive program. 26 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

Appendix About this report 28 Our sustainability governance and strategy 29 Data summary 34 TCFD disclosure update 39 GRI content index 42 SASB index 46 Aligning with the United Nations 47 Sustainable Development Goals (SDGs) Endnotes 48 27 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix

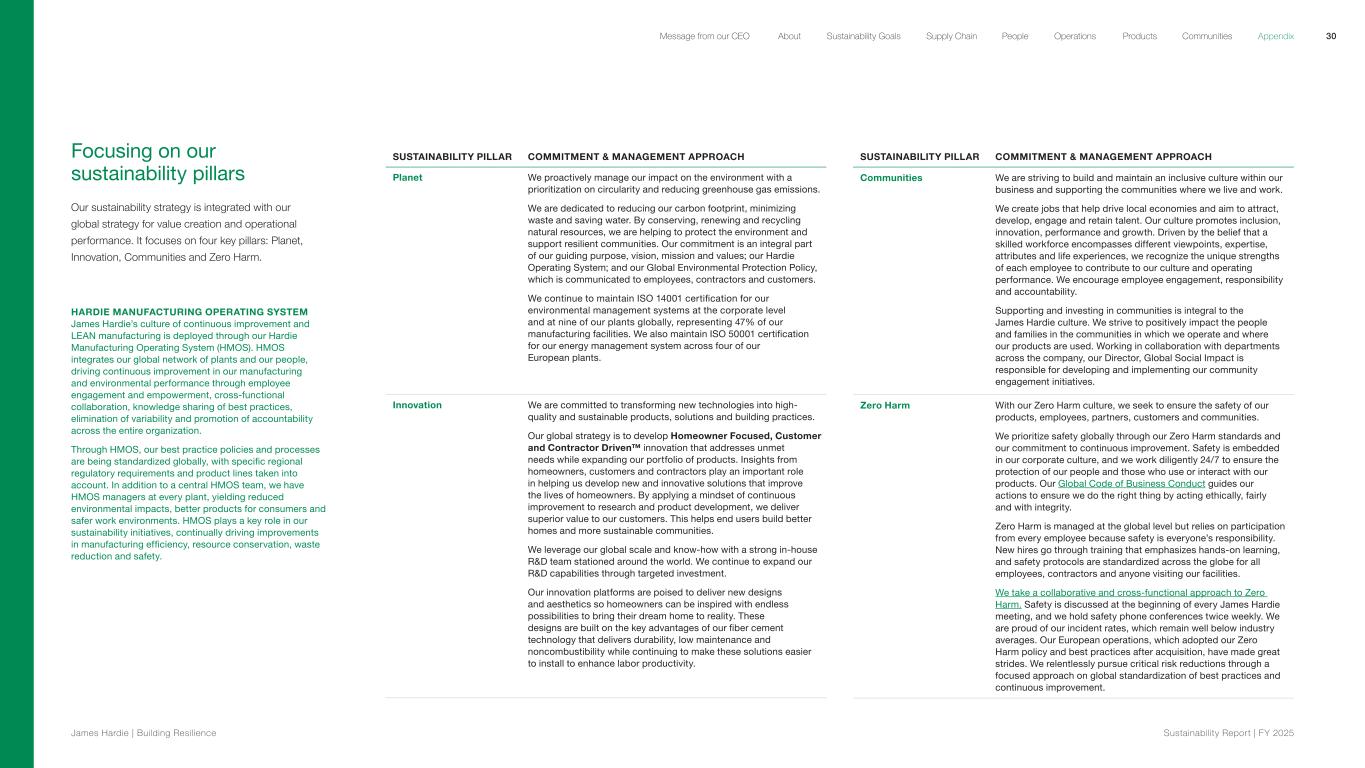

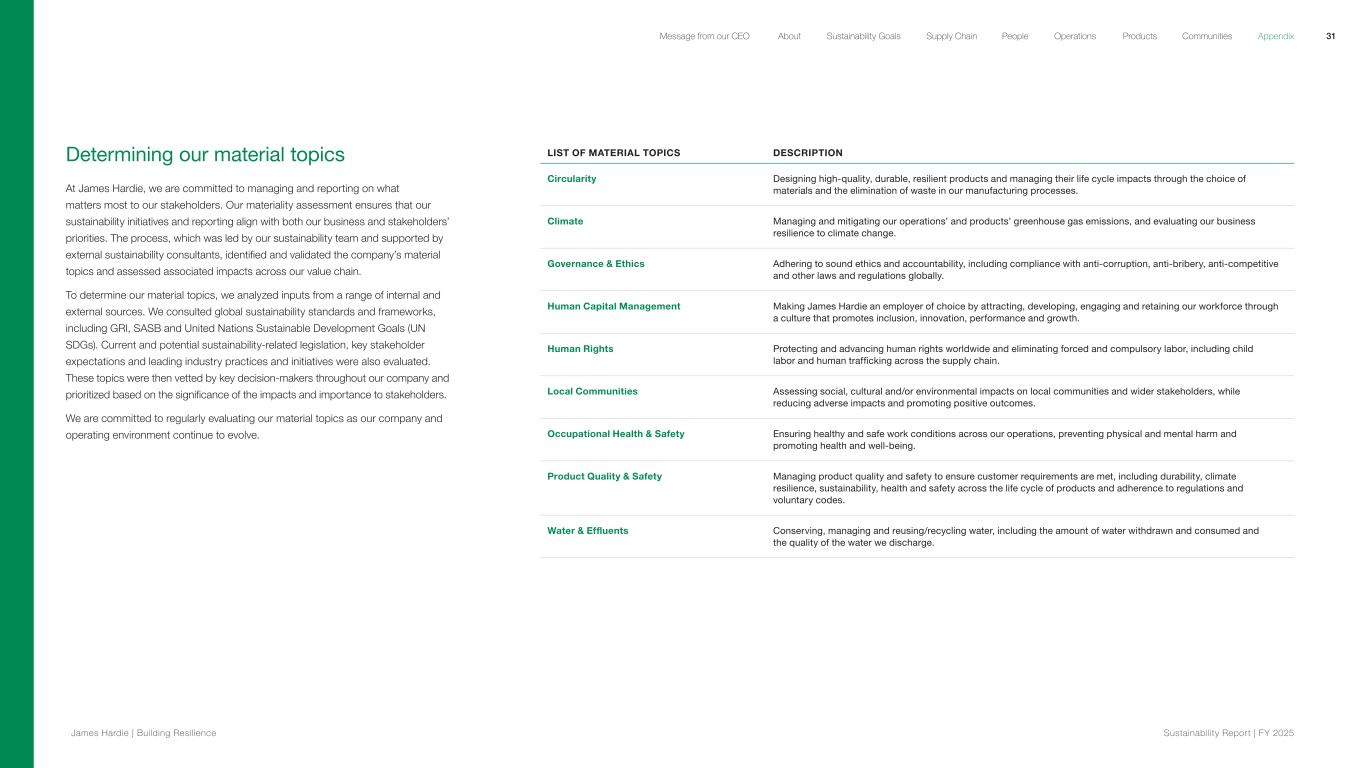

About this report This is James Hardie’s fifth annual sustainability report. It covers our sustainability performance progress for fiscal year 2025 (1 April 2024 through 31 March 2025) across our global operations and highlights our priorities. Environmental data is collected and reported on a calendar rather than a fiscal year basis. Any other exceptions to the reporting period are noted within the report. It has been prepared with reference to the GRI (Global Reporting Initiative) Sustainability Reporting Standards 2021. As our sustainability program progresses, we are committed to aligning with best practice reporting standards and frameworks, including those set forth by GRI, the Sustainability Accounting Standards Board (SASB) and the Task Force on Climate-related Financial Disclosures (TCFD). As of 01 July 2025, James Hardie has acquired The AZEK Company Inc. Data in this report include all sites under James Hardie’s operational control during FY25 (except where noted). Future reports will include performance data from the consolidated company. All monetary figures are in U.S. dollars unless otherwise indicated. We welcome your comments and feedback at [email protected]. 28 James Hardie | Building Resilience Sustainability Repor t | FY 2025 About Sustainability Goals Supply Chain OperationsMessage from our CEO People Products Communities Appendix