Supply

Chain Steve

Conaway

–

Supply

Chain

Manager

Ryan

Kilcullen

–

Supply

Chain

Engineer

Investor/Analyst

USA

Tour

–

10

&

11

September

2012

Exhibit 99.3 |

Supply

Chain Steve

Conaway

–

Supply

Chain

Manager

Ryan

Kilcullen

–

Supply

Chain

Engineer

Investor/Analyst

USA

Tour

–

10

&

11

September

2012

Exhibit 99.3 |

AGENDA

•

Supply

Chain

Overview

–

Primed

and

ColorPlus

®

Models

•

Evolution of Order Entry

•

Production Planning

•

Manufacturing Models

•

Distribution Network

•

Transportation Optimization |

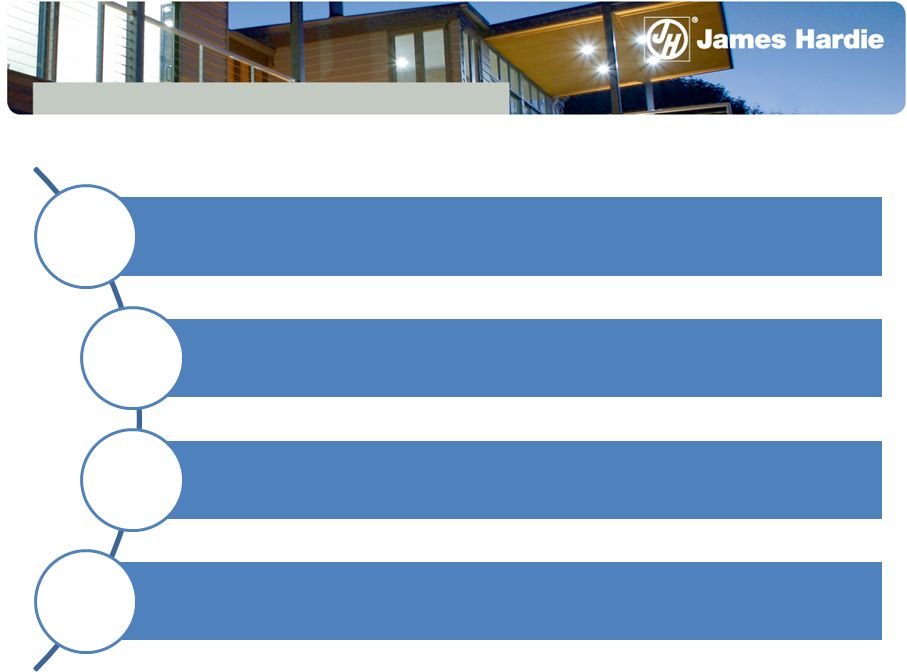

SUPPLY

CHAIN •

Demand Planning

•

Capacity Matching

•

Made to Inventory

•

Made to Order

•

JH Warehouses

•

Customer Channel

•

VMI

•

Reload Centers

•

Customer Orders

•

Distribution Replenishment Orders

•

Rate Optimization

•

Mode Optimization

•

Spot Market Pricing

•

Centralized & De-centralized

Supply Chain Structure

Order Entry

Production

Planning

Procurement

Manufacturing

Distribution

Network

Transportation |

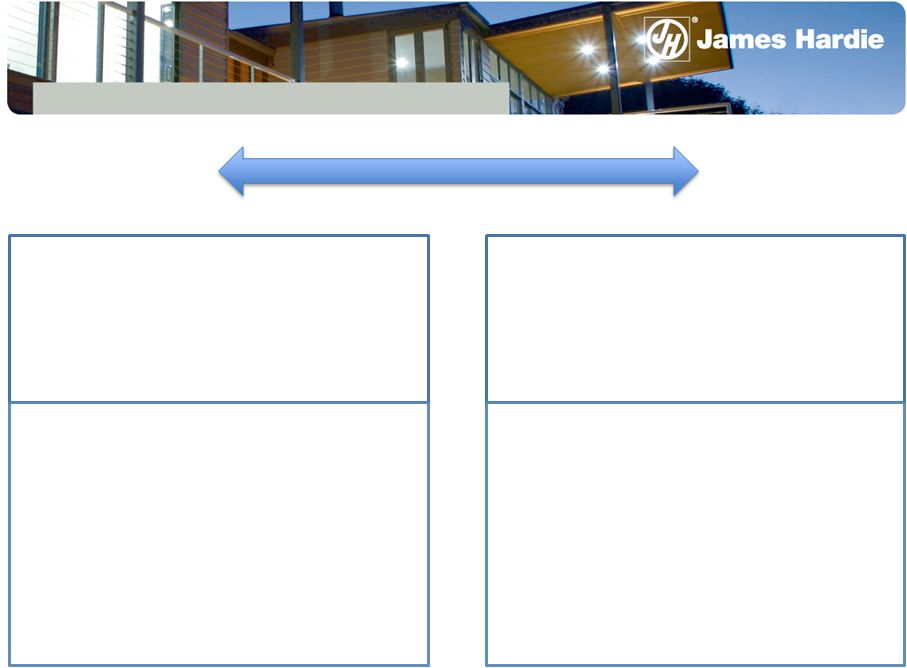

Lower

Complexity

Supply Chain

Higher

Complexity

Supply Chain

SUPPLY CHAIN

Primed Supply Chain

ColorPlus

®

Supply Chain

•

Relatively small SKU set

•

Low complexity orders

•

Made to inventory

•

14 day lead times

•

Full pallet orders

•

7 manufacturing locations

•

Large SKU set

•

High complexity orders

•

Made to order

•

8 day lead times

•

Orders to the piece

•

4 manufacturing locations |

SUPPLY

CHAIN

–

ORDER

ENTRY

Evolution of Order Entry

Manual

Order

Entry

EDI

HardieLink

•

Gives customer ability to order material, check order status, obtain

pricing and view technical support / training real time

•

Option to use EDI which provides immediate feedback on order errors

•

Electronic Data Interchange

•

Allows for customer to enter order in their system and electronically send

to JH system

•

Historically high error rate

•

Phone, fax or emails received and processed by customer service rep

•

Slow process (up to 1.5 days to enter order) |

SUPPLY

CHAIN

–

PRODUCTION

PLANNING

Demand Planning

3 to 10

Years

<3

Years

<12

Months

<3

Months

-

# and Location of Manufacturing Sites

-

Basis is Plan for Category and Market Share Growth

along with Housing Market Assumptions

-

Capacity and Product Specific Additions

-

Basis is mid range demand forecast

-

Sales and Operations Planning Process

-

Monthly review

-

Capacity Control Charts

-

Weekly Adjustments and Demand Sourcing

Long Term Planning

Mid Term Planning

Short Term Planning

Short Term Planning |

SUPPLY

CHAIN – PRODUCTION PLANNING

Production Planning

•

Capacity Planning Processes

–

Advanced Planning and Optimization (APO)

•

Made to order model

•

Products

utilizing

ColorPlus®

Technology

•

VMI replenishment

–

Core inventory planning method

•

Made to inventory model

•

Flat sheets planning method |

JH FLAT

SHEET PRODUCTION PLANNING & SCHEDULING The

JH

business

model

continues

to

evolve

from

a

primed

model

to

a

model

featuring

ColorPlus

®

Technology

and

a

more

differentiated

product offering

This has impacted our production planning in the following ways:

•

Shorter customer lead times

•

Increased number of SKUs

•

Increased complexity in changeover set-ups

•

Greater disaggregation of our inventory

While still using our “primed”

model production planning logic, we

began to see concerning trends in our network:

•

Inconsistent on-time service performance

•

Sub-optimal production sequencing on our manufacturing lines

•

Regional imbalances in short-term manufacturing capacity

|

CHANGING

OUR APPROACH A current-state gap analysis was conducted and identified

two primary drivers of our problems:

1.

We were running a completely centralized model when significant

efficiencies could be gained from local control

2.

We lacked a robust system to react quickly to regional changes in short-

term capacity

A pilot program was designed and implemented at one of our

manufacturing sites to address these deficiencies |

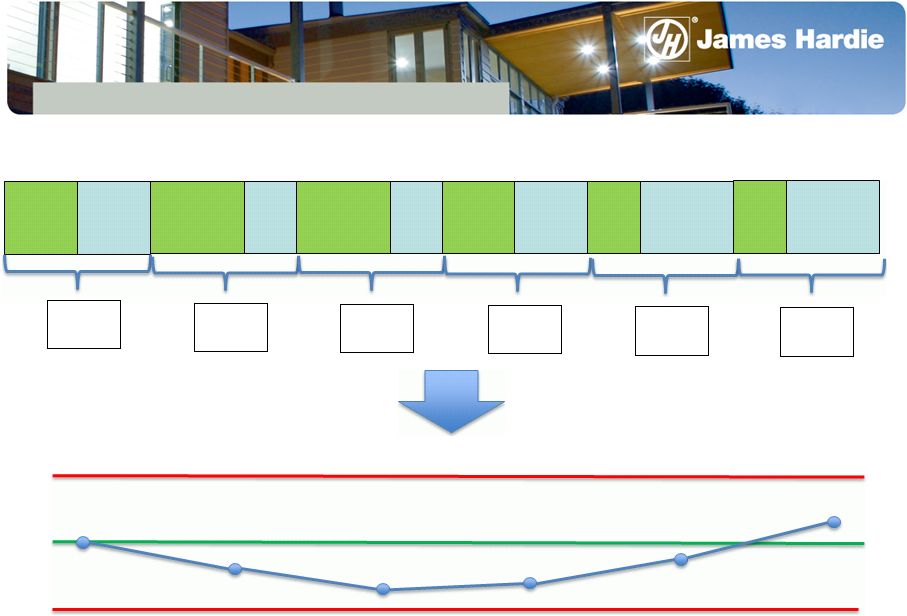

KEY

ELEMENTS OF OUR RE-DESIGNED PROCESS Production scheduling was

decentralized to the plant-level to achieve the following

benefits: •

Faster response to changes in demand trends with continuous planning

•

Optimal production sequencing with a greater understanding of

manufacturing costs

•

More forward looking planning tools to enable the plant to better manage

labor and scheduled production hours

A proactive approach to short-term capacity management was

developed

•

Variation in week-to-week demand is buffered by “core”

SKUs

–

This enables consistent production schedules with minimal inventory buffer

•

Regional capacity is managed via capacity control charts with established

action limits that trigger capacity moves |

CONNECTING PLANNING TO CAPACITY MANAGEMENT

Week

1

Week

2

Week

3

Week

4

Week

5

Week

6

Manufacturing Block Schedule

Capacity Control Chart

Upper Control Limit

Lower Control Limit

Target

NC

C

NC

C

NC

NC

NC

NC

C

C

C

C |

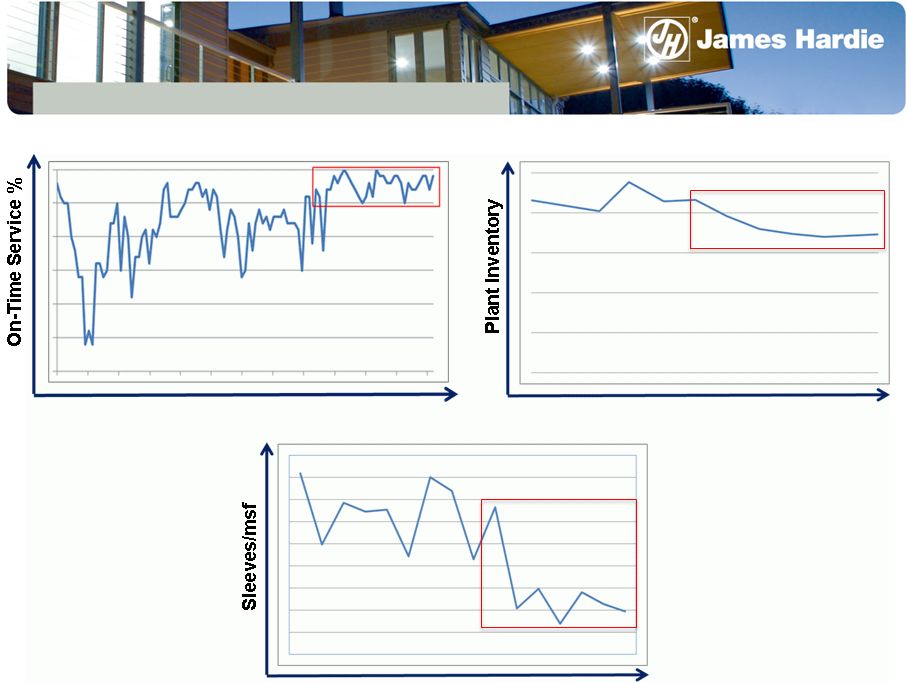

A SAMPLE

OF PILOT PROGRAM RESULTS Pilot Plant Weekly On-Time Service Results

Pilot Plant Make-Item Inventory Level

Pilot Plant Sleeve Consumption

Time

Time

Time |

MANUFACTURING PLANNING NEXT STEPS

•

We are currently implementing the plant production scheduling

program in all plants

•

We are capacity control charting all flat sheet plants

•

Next steps:

–

Develop line-specific control charts where necessary

–

Implement control charting in non-flat sheet manufacturing processes

|

MANUFACTURING

–

SUPPLY

CHAIN

•

Made to Inventory Model

–

Primed Model

–

14 day lead times

–

Full pallet orders

–

Single sourced products

•

Made to Order Model

–

ColorPlus

®

Model

–

Orders to the piece

–

8 day lead times |

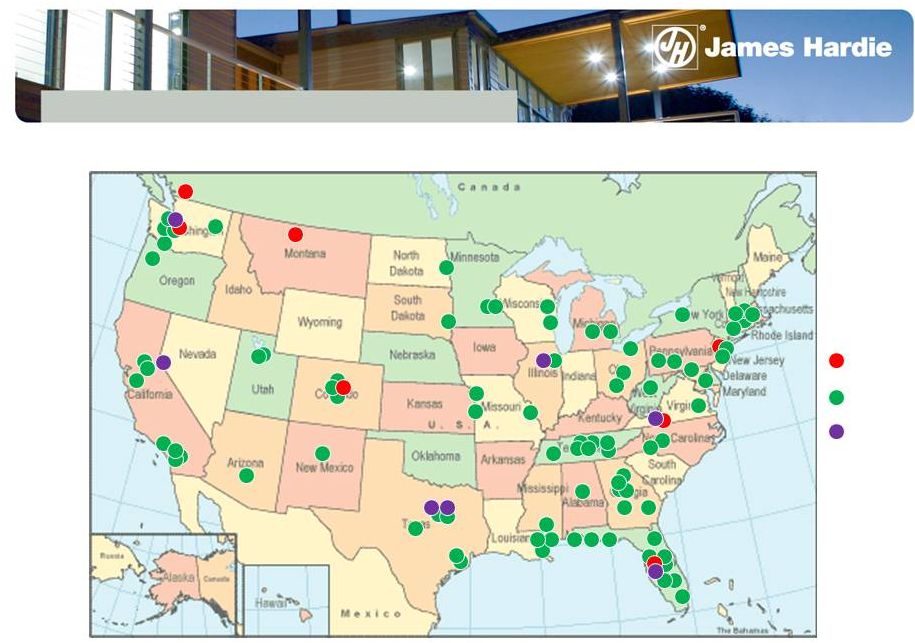

DISTRIBUTION

NETWORK

–

SUPPLY

CHAIN

•

7 Manufacturing

Locations

(4

with

ColorPlus

®

Technology)

•

Vendor Managed Inventory Sites (VMI)

–

Enables ColorPlus

®

Technology business by improving customer

access to product and full SKU range

–

Improved demand signal

–

Improved line of sight on end sales data

•

Reload Centers

–

Enables freight optimization

–

Reduces lead time on customer orders and distribution replenishment

|

DISTRIBUTION

NETWORK

–

SUPPLY

CHAIN

Reload

VMI

Plants |

TRANSPORTATION

–

SUPPLY

CHAIN

Primed Products

ColorPlus

®

Technology Products

7 Manufacturing Locations

Full Truck Loads

<500 mile shipping radius

4 Manufacturing Locations

Less Than Full Truck Loads

>500 mile shipping radius

Multi-stop loads

Higher rate lanes / regions

Cross-docking |

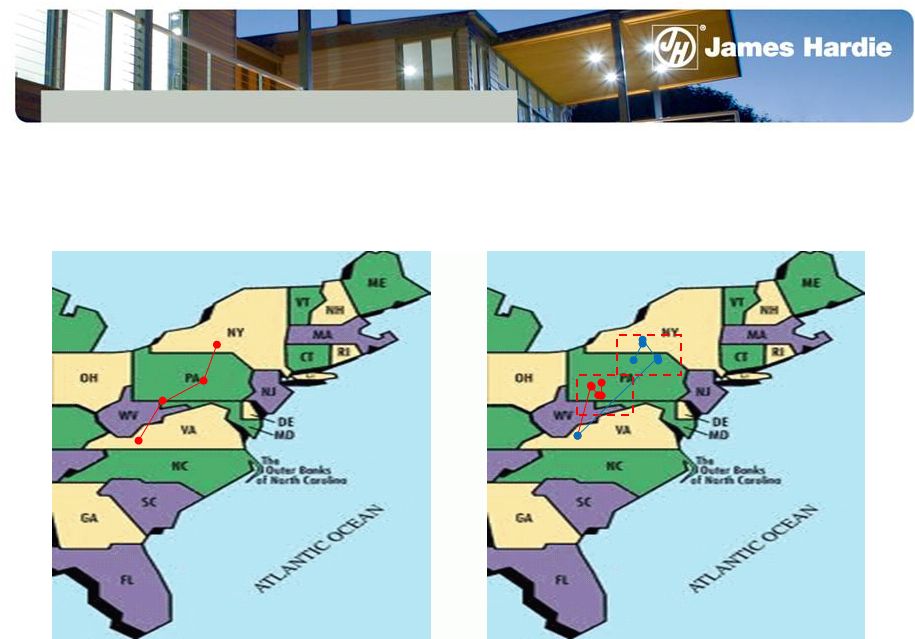

MODE

OPTIMIZATION

–

SUPPLY

CHAIN

Rail and Truck

Truck, Rail, Intermodal

Utilize rail/intermodal for long

distances to reload distribution

centers

Truck to customers

Cross dock to minimize

necessary inventory at reload

distribution centers |

MULTI-STOP

OPTIMIZATION

–

SUPPLY

CHAIN

Bead Approach

Lollipop Approach |

SUMMARY

–

SUPPLY

CHAIN

•

Increased

supply

chain

complexity

with

ColorPlus

®

Technology

•

Utilize supply chain to provide value to channel

•

Order entry process has evolved with order complexity

•

Planning process focused on long, mid and short term demand

•

Change to core inventory planning method

•

Optimize transportation and distribution to minimize cost

|

Questions |