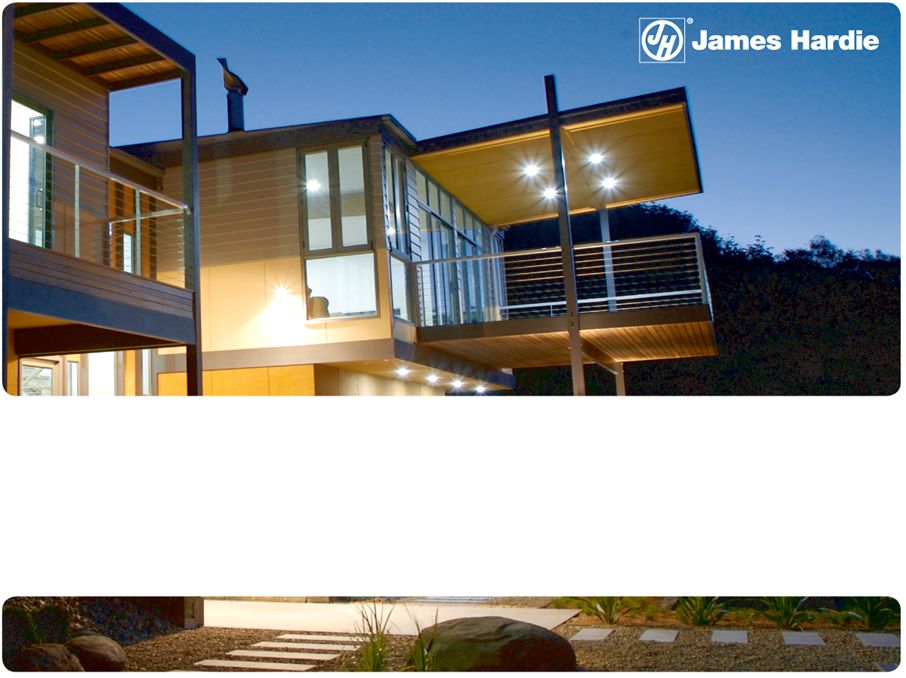

ColorPlus

®

Technology

Ryan Sullivan –

Director of ColorPlus Business

Tyler Hart –

ColorPlus Engineering Manager

Investor/Analyst USA Tour –

10 & 11 September 2012

Exhibit 99.4 |

ColorPlus

®

Technology

Ryan Sullivan –

Director of ColorPlus Business

Tyler Hart –

ColorPlus Engineering Manager

Investor/Analyst USA Tour –

10 & 11 September 2012

Exhibit 99.4 |

AGENDA

•

Business Organization

•

R&D Update

•

Market Update

–

Job Pack Review

–

VMI Review

–

HardieLink

®

–

Product Expansion

•

Manufacturing

–

Challenges

–

Future State |

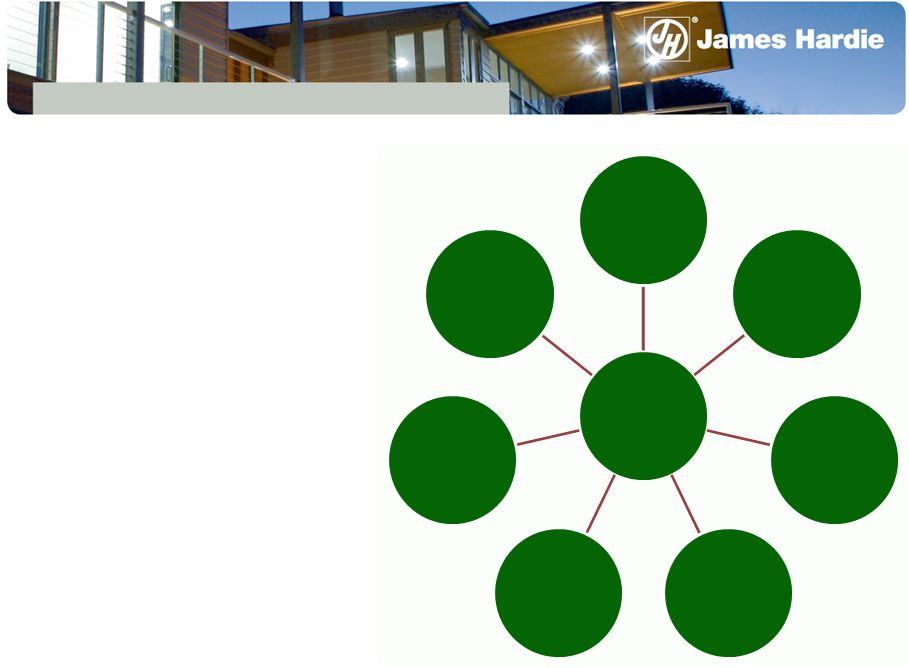

Business Organization |

•

James Hardie has a

dedicated

business

management team that is

responsible for setting strategy

for ColorPlus

®

Technology and

interfacing with other functions

within James Hardie.

•

The ColorPlus

®

Technology

team consists of:

-

Manufacturing

-

Supply Chain

-

Product Management

-

R&D

-

Future State Engineering

-

Channel Interface

-

Finance

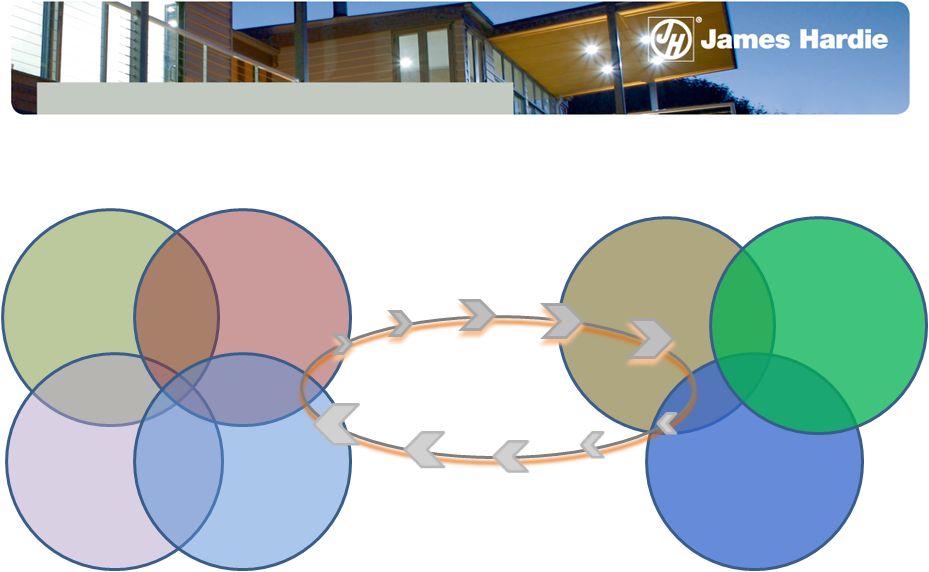

ORGANIZATIONAL STRUCTURE

Manufacturing

Sales

Product

Management

Marketing

ColorPlus®

Technology

Team

Segment

Management

Product R&D

Channel

Management |

ColorPlus

®

Technology R&D |

JH

Color R&D

Product

Leadership

Product

Design

Product

Performance

COLORPLUS

®

TECHNOLOGY R&D |

Analytical

Application

Pilot-Line

Product

Testing

FC Material

Science

Sealers

Primers

Top-Coats

Specialist/

Dedicated

Resources

Industry

Consultants

R&D CAPABILITIES |

•

Research

Center

–

Chicago

–

65,000sf R&D facility: operational

from Q3 FY13

•

Equipment Capabilities

–

State of the art analytical equipment, testing &

application pilot-line; industry leading R&D

investment

•

Resources

–

10 scientists/engineers dedicated towards

ColorPlus Technology R&D: paint specialists,

polymer scientist, application engineers

R&D CAPABILITIES |

Before

Weathering

After

Weathering

JH C+

Vinyl

Field Paint

R&D CAPABILITIES

Current Focus

Ramp-up Internal Capabilities

Future Focus

Autonomous Color Expertise

Areas of Focus

Areas of Focus

Facilities ramp-up

Resources

Science behind paint

Competitor bench-marking

Internal color expertise

Color R&D/Innovation to propel

JH’s growth

Science behind

paint/performance based

design |

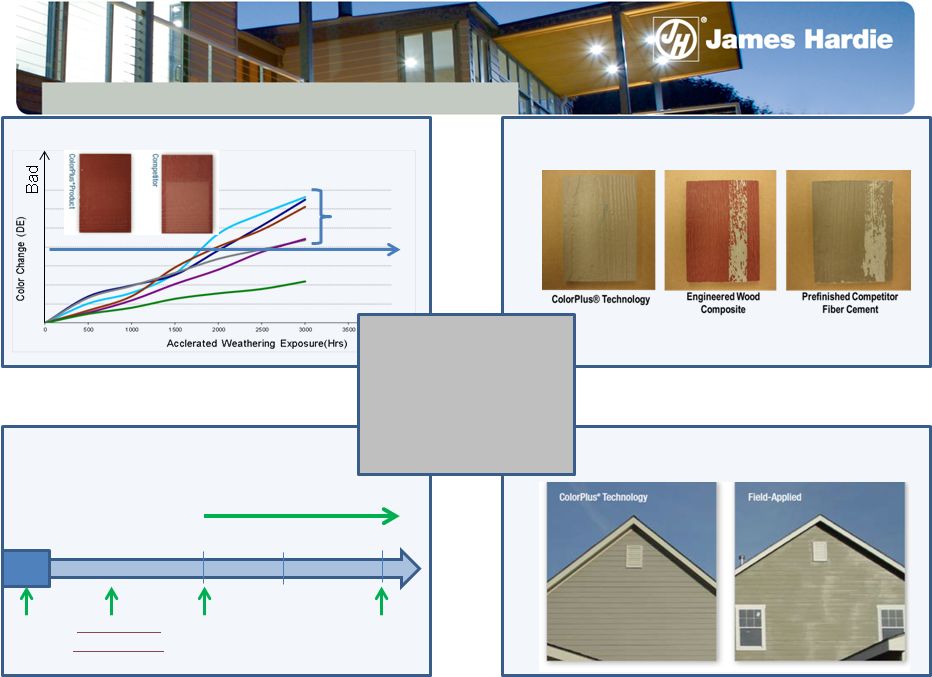

Better Paint Adhesion than Field Paints and

Prefinished Competitor Fiber Cement

Paint

Adhesion

–

Freezing

Wet

Conditions (Effect of Tape Pull Test)

Better Paint Application when

Compared to Field Applied Paint

0.0

1.0

0.5

0.7

Better Fade Resistance than Field Paint & Competitors

ColorPlus

Technology

Visually

Noticeable

Field Paints/

Competitors

ColorPlus

®

Technology

Car Refinish

Standard

Acceptable at Most

Paint Stores &

Prefinishers

Zero

Difference

Visually Different

Better Color Consistency than

Field Paints & Prefinishers

COLORPLUS®

TECHNOLOGY PERFORMANCE

ColorPlus

®

Technology vs.

Field Applied

Paints &

Competitor Siding

dE |

ColorPlus

®

Technology Market |

MARKET

CONFIGURATION PROGRESS Last year we said we would deliver on four key programs:

•

Open additional Job Pack markets

•

Vendor Managed Inventory (VMI) network expansion

•

Channel Interface launch – HardieLink

®

•

Manufacturing capability enhancements for ColorPlus

®

Technology

We have made significant progress on all of these programs and more.

|

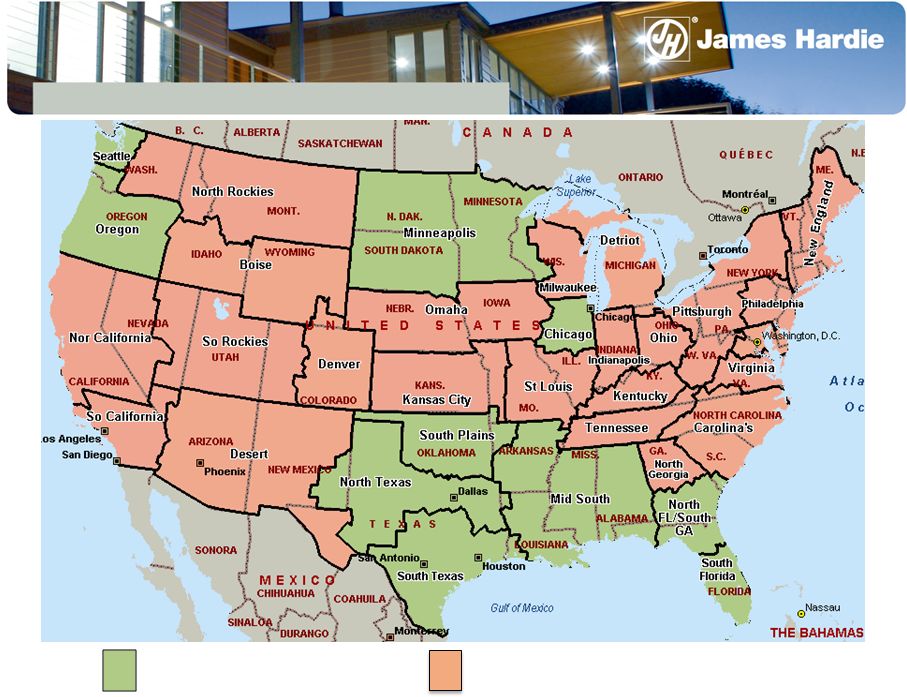

Job Pack Markets

Non-Job Pack Markets

JOB PACK MARKETS CY2011 |

Job Pack Markets

JOB PACK MARKETS CY2012 |

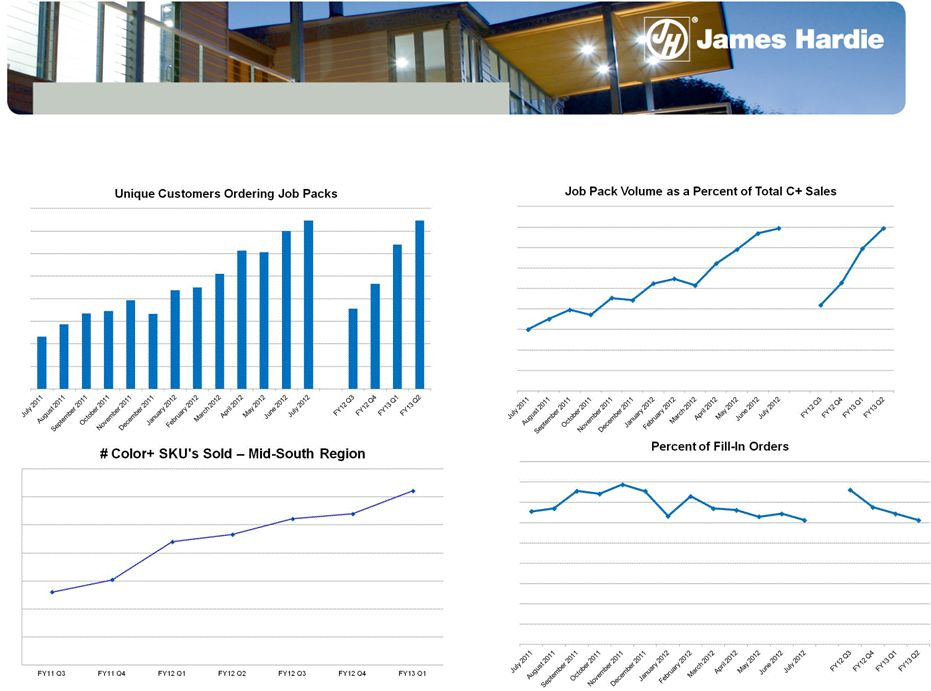

JOB PACK

PERFORMANCE Job Packs continue to grow significantly.

|

VMI –

Color

VMI –

Cem only

JHBP Plants

VMIs –

CY2011 |

VMI –

Color

VMI –

Cem only

JHBP Plants

VMIs CY2012 |

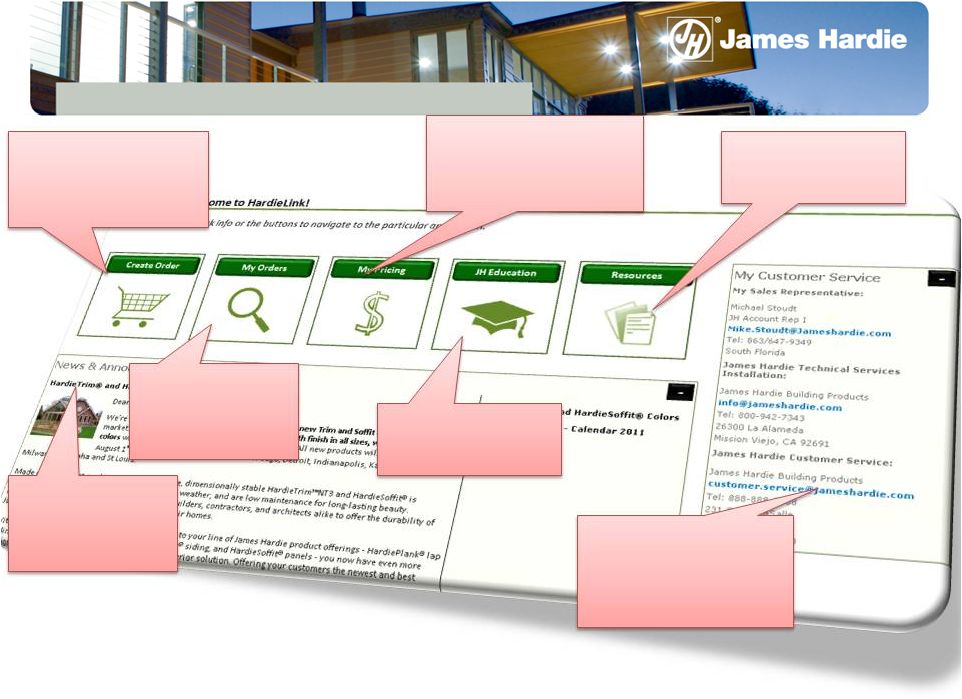

CHANNEL

INTERFACE – HARDIELINK®

•

Create Quotes

•

Generate Proposals

•

Submit Orders

•

View/Print Price

Pages (w/Markup)

•

Download Pricing

•

Hardie News

•

Industry News

•

Order Status

•

Shipping Status

•

Material Status

•

Sales Representative

•

Install Representative

•

Customer Service

•

Technical Service

•

Access Training

Modules

•

Access Marketing

Library

Central customer communication hub |

29%

Of Orders

350+

Order Entry Locations

800+

HardieLink Users

HARDIELINK®

ADOPTION |

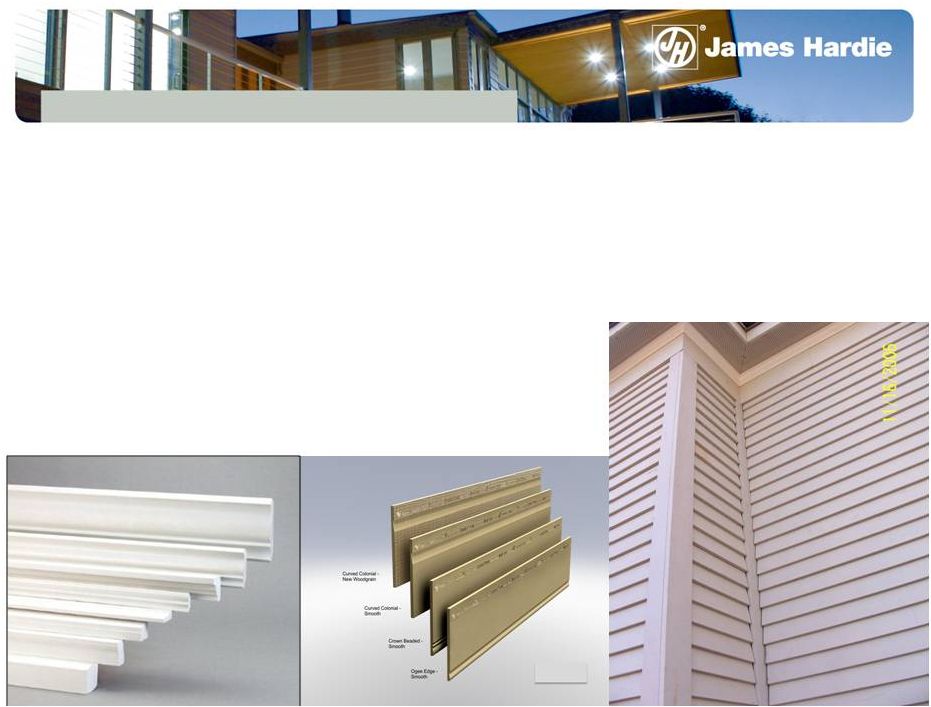

EXPANDED

PRODUCTS FOR FULL WRAP Continue

to

expand

products

with

ColorPlus

®

Technology

to

drive

the

full

wrap

in

all

segments:

•

•

•

Artisan

®

Shaped

Trim

Differentiated

Planks |

ColorPlus

®

Technology Manufacturing |

Manufacturing

Challenges

with

ColorPlus

®

Technology:

•

•

Future

State

Manufacturing:

•

•

COLORPLUS

®

TECHNOLOGY MANUFACTURING

Product

Scope

Service

Offering

Pulaski

Job

Pack

Stacker

Multi

Line

Plants |

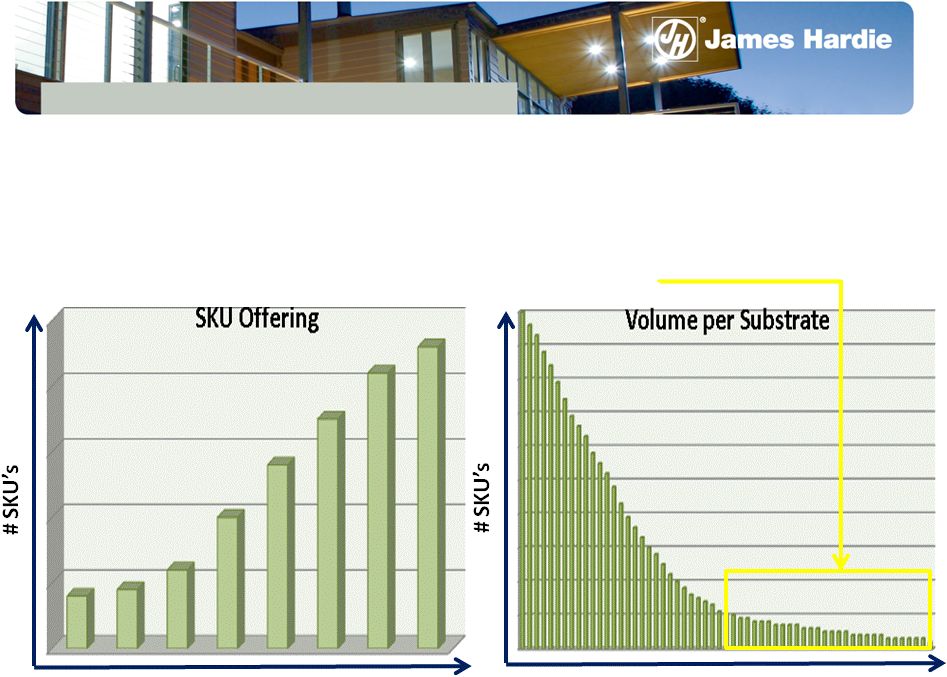

Product Scope

•

Increased Color Offering

•

Increased Substrate Offering

•

Sales moving toward tail end products

MANUFACTURING CHALLENGES

YEARS

SUBSTRATES |

Service Offering –

Job Packs

What is a Job Pack:

•

Order

products

with

ColorPlus

®

technology

to

the

piece

•

Job

Packs

are

sold

to

Channel

Partners

and

cross

docked

to

end-user

Why do we do it:

•

Shorter Lead time: Previously a Made To Order (MTO) product would take four weeks

for a delivery. •

Allows customers access to our full range of products without penalties

•

Less

Cost:

Added

costs

are

put

into

the

product

when

it

is

stacked

down

or

has

additional

stops

in

the

channel

•

JHBP can do this on line with greater efficiency:

•

End result is higher customer satisfaction and less waste

MANUFACTURING CHALLENGES

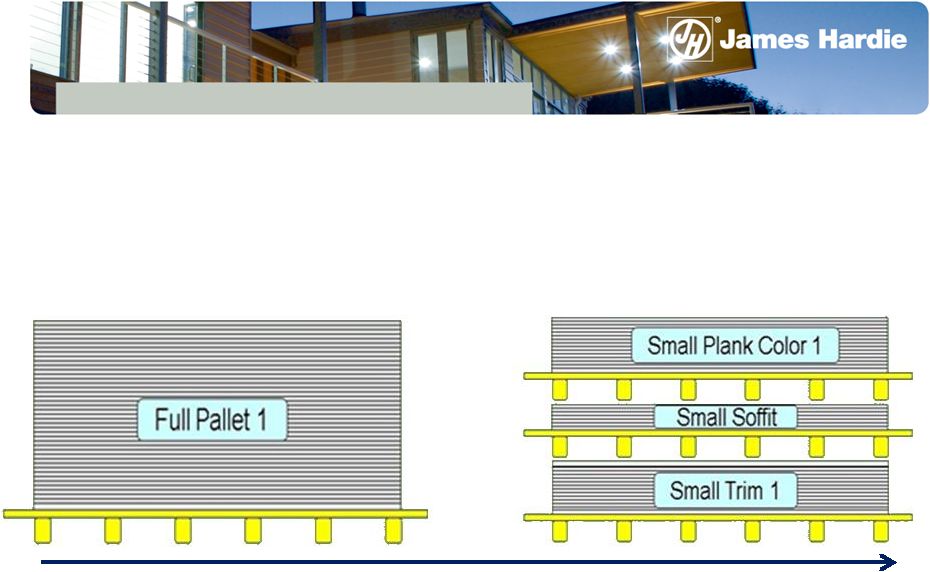

These 5 pallets reflect an order for a house based on

fulls, mids, and minis. Fixed pallet quantities resulted in

excess material on job sites and delivery time of up to

four weeks.

This shows same order based on the new job

pack program with minimal waste and delivery

time under two weeks. |

Service Offering –

Job Packs

•

Higher Material Cost

•

Lower Labor Efficiency

•

Lower Line Efficiency

Original Business Model

•

•

•

Current Business Model

•

•

•

MANUFACTURING CHALLENGES

Minimum Labor Touches

1 product -

1 pallet

2000sqft

Multiple Labor Touches

3 product -

3 pallets

2000sqft |

The situation in ColorPlus

manufacturing has changed:

1.

•

•

•

Simulation

Pulaski Job Pack stacker:

•

•

FUTURE STATE COLORPLUS

®

TECHNOLOGY

On line packaging

Line rate improvement

Higher

operational

cost

–

Job

Packs:

Efficiency

Materials

Labor |

The situation in ColorPlus manufacturing has changed:

2.

•

Two Line Model

Made

To

Inventory

(MTI/CORE)

Line

–

high

capacity

•

•

•

Made

To

Order

(MTO)

Line

–

lower

capacity

•

•

•

FUTURE STATE COLORPLUS

®

TECHNOLOGY

Labor utilization on par with MTI Line

Very good at lower volume products

Highly flexible to color cycle and substrate demand

Highly efficient on material yields

Highly efficient on product mix

Long runs on single products and single colors

Line rates don’t match mix and/or complexity

Performance and engineering gaps: |

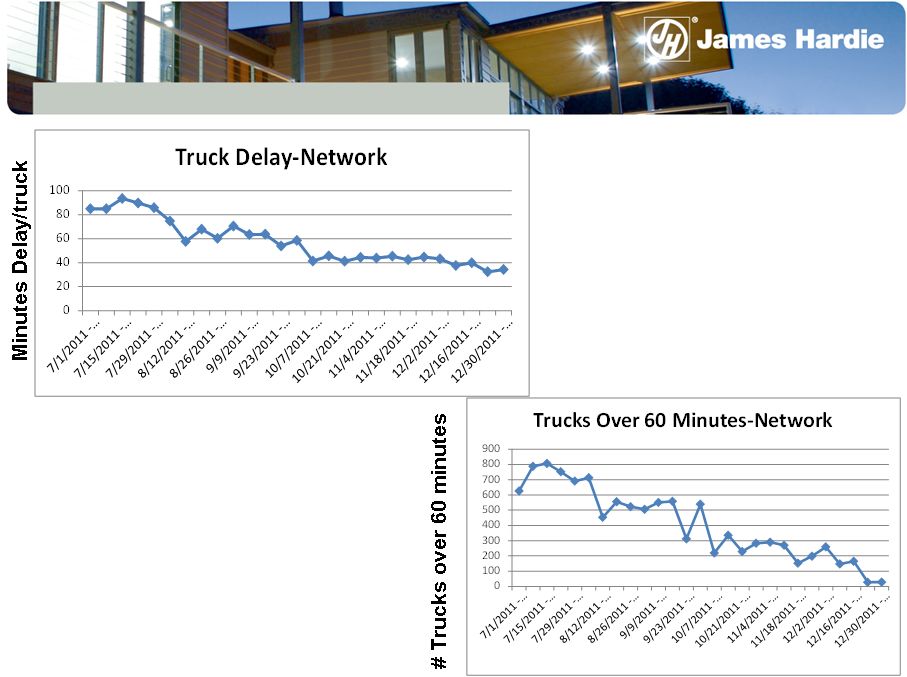

•

Network overall is showing

sustained improvement

•

Non-C+ Facilities are still

holding good times

•

Implementing truck

validation in Plant City,

Tacoma and

Waxahachie plants

•

C+ Facilities are continuing to

show progress with average

delay under 60 min for 13

weeks

•

Investigating better visibility

for staging with APO

technology

PLANT PROCESS REDESIGN |

Questions |