Asia

Pacific Manufacturing Danny De Guzman

Investor/Analyst

Update

–

19

September

2012

Exhibit 99.14 |

Asia

Pacific Manufacturing Danny De Guzman

Investor/Analyst

Update

–

19

September

2012

Exhibit 99.14 |

•

Asia Pacific Manufacturing History

•

Operational Philosophy

•

Asia

Pacific

Manufacturing

–

Onward

•

Capacity

AGENDA |

LONG

TERM EVOLUTION 1980s:

Converted

from

AC

to

Fibre

Cement

(FC)

Technology

•

Converted our entire product capability to FC

1990s:

Increased

Machine

Efficiency

with

FC

Technology

•

Higher throughput per Machine

•

Evolved

Technology

on

Sheet

Machine

–

Pressed

Products,

Tub/Feed

Technology

•

Consolidated

Multiple

Factories

to

Three

Sites

(two

in

AUS,

one

in

NZ)

•

Constructed our Philippines Plant

TM

2000-2005:

Capacity

for

Finishing

Processes

•

Increased our capacity in Finishing

•

Further developed our product portfolio through finishing processes

•

Relocated

our

WA

operations

to

Carole

Park

-

Corrugate

Products

2005-2012:

Developed

our

Scyon

Technology

•

New Technology to Unlock Market Value |

CURRENT

STATE Manufacturing Sites

•

Rosehill, NSW

–

25mmstdm, Scyon

TM

, Flooring

•

Carole Park, QLD

–

18mmstdm, Pressed Products

•

Penrose, New Zealand

–

11mmstdm, Scyon

TM

•

Cabuyao, Philippines

–

19mmstdm |

1990

– 2005

•

Throughput focused

•

Core product portfolio developed

•

Engineering driven

•

Single sourced specialty products

OPERATIONAL PHILOSOPHY |

2005

– 2010 (New Product Development)

•

Focus on New Product Development

-

Scyon

Product

Range

-

Exterior Cladding

-

Flooring

•

New product learning curve

-

Increased complexity in factories

-

From single step manufacturing to multiple steps

•

Increased Service Promise

-

Reduced lead time

-

Developed new models for planning and logistics

OPERATIONAL PHILOSOPHY

TM |

2010

– 2012 (Operational Efficiency)

•

Bed-in operational complexity

-

Focus on efficiency

•

Utilisation and spend focus to reduce costs

-

Treat all costs (except depreciation, tax and insurance) as variable

-

Minimize waste

-

Cost per hour

*

Scalable, linear

-

Lowest delivered cash cost to market

•

Key areas of success

-

Developed better model for matching supply and demand and allowing

flexibility -

Improved ability to manufacture more complex SKU mix

OPERATIONAL PHILOSOPHY |

ASIA PAC

MANUFACTURING – ONWARD |

2012

– Onward

•

Product leadership

-

Continuous manufacturing improvement of current products

-

Available capacity to develop new products and meet demand

*

Long

term

capacity

review

–

ongoing

•

Low cost manufacturing

-

Long continuous run

*

Duration vs. frequency of delay

*

Higher utilisation of existing capacity

-

Variable spend/cost

*

Treat all spend/cost as variable

ASIA PAC MANUFACTURING –

ONWARD |

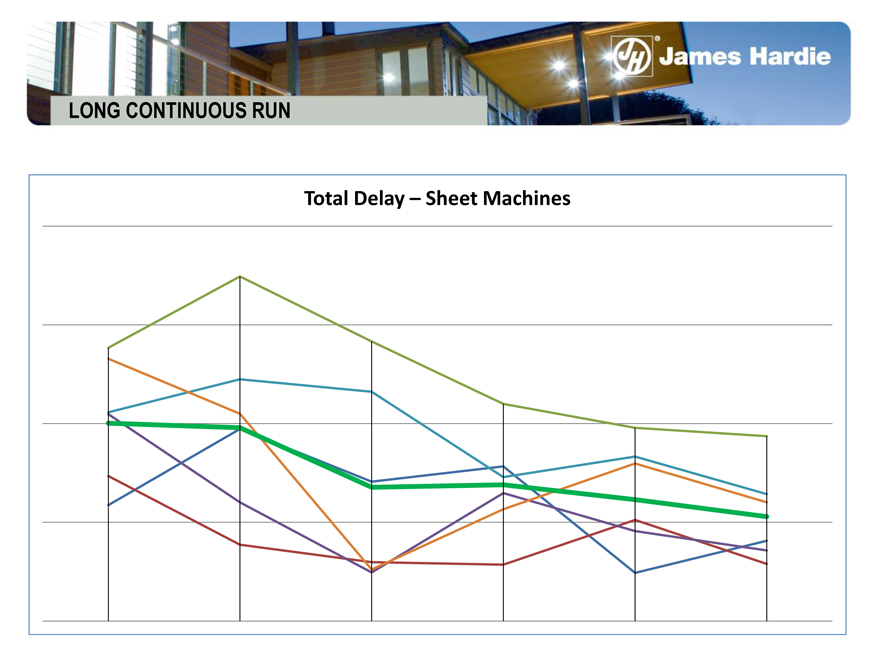

LONG CONTINUOUS RUN

Total Delay – Sheet Machines

ASIA

PAC MANUFACTURING Summary

•

Manufacturing aligned to business strategy

•

Imperatives are clear:

-

Deliver on product promise

-

Low cost manufacturing

•

Framework to drive initiatives in place

-

Focus on execution and continuous improvements

•

Execution of initiatives on-going

-

Early

traction

–

more

work

ahead

of

us

-

Capacity

–

study

ongoing

+

recommendation

pending

•

Organizational development and safety approach in place

-

We’ve got the right people

-

Capability and execution improving |

Long Term Capacity

•

Capacity

review

team

–

in

place

•

Capacity

review

–

ongoing

•

Recommendation

–

pending

•

Preliminary insights

-

Land component higher vs. USA capacity projects

-

Labor for construction and operations higher vs. USA capacity projects

-

Input

material

and

freight

costs

–

potential

major

drivers

•

Capacity study further work:

-

Determine size of capacity addition

-

Determine product capability in new capacity

AUSTRALIA CAPACITY REVIEW |

Questions |