MANUFACTURING CAPACITY

Tyler Hart

24 September 2014

Exhibit 99.2 |

MANUFACTURING CAPACITY

Tyler Hart

24 September 2014

Exhibit 99.2 |

DISCLAIMER

2

This Management Presentation contains forward-looking statements. James Hardie may from time to

time make forward-looking statements in its periodic reports filed with or furnished to the

SEC, on Forms 20-F and 6-K, in its annual reports to shareholders, in offering circulars, invitation memoranda and prospectuses, in media releases and other written

materials and in oral statements made by the company’s officers, directors or employees to

analysts, institutional investors, existing and potential lenders, representatives of the media

and others. Statements that are not historical facts are forward-looking statements and such

forward-looking statements are statements made pursuant to the Safe Harbor Provisions of

the Private Securities Litigation Reform Act of 1995.

Examples of forward-looking statements include: •

statements about the company’s future performance; •

projections of the company’s results of operations or financial condition; •

statements regarding the company’s plans, objectives or goals, including those relating to

strategies, initiatives, competition, acquisitions, dispositions and/or its products;

•

expectations concerning the costs associated with the suspension or closure of operations at any of

the company’s plants and future plans with respect to any such plants;

•

expectations concerning the costs associated with the significant capital expenditure projects at any

of the company’s plants and future plans with respect to any such projects;

•

expectations regarding the extension or renewal of the company’s credit facilities including

changes to terms, covenants or ratios;

•

expectations concerning dividend payments and share buy-backs; •

statements concerning the company’s corporate and tax domiciles and structures and potential

changes to them, including potential tax charges;

•

statements regarding tax liabilities and related audits, reviews and proceedings; •

statements regarding the possible consequences and/or potential outcome of the legal proceedings

brought against two of the company’s subsidiaries by the New Zealand Ministry of Education

and the potential product liabilities, if any, associated with such proceedings;

•

expectations about the timing and amount of contributions to Asbestos Injuries Compensation Fund

(AICF), a special purpose fund for the compensation of proven Australian asbestos-related

personal injury and death claims;

•

expectations concerning indemnification obligations; •

expectations concerning the adequacy of the company’s warranty provisions and estimates for

future warranty-related costs;

•

statements regarding the company’s ability to manage legal and regulatory matters (including but

not limited to product liability, environmental, intellectual property and competition law

matters) and to resolve any such pending legal and regulatory matters within current estimates and in anticipation of certain third-party recoveries; and

•

statements about economic conditions, such as changes in the US economic or housing recovery or

changes in the market conditions in the Asia Pacific region, the levels of new home

construction and home renovations, unemployment levels, changes in consumer income, changes or stability in housing values, the availability of mortgages and

other financing, mortgage and other interest rates, housing affordability and supply, the levels of

foreclosures and home resales, currency exchange rates, and builder and consumer confidence. |

3

Words such as “believe,” “anticipate,” “plan,” “expect,”

“intend,” “target,” “estimate,” “project,” “predict,” “forecast,” “guideline,” “aim,” “will,” “should,” “likely,” “continue,”

“may,” “objective,” “outlook” and similar expressions are

intended to identify forward-looking statements but are not the exclusive means of identifying such statements. Readers are

cautioned not to place undue reliance on these forward-looking statements and all such

forward-looking statements are qualified in their entirety by reference to the following

cautionary statements.

Forward-looking statements are based on the company’s current expectations, estimates and

assumptions and because forward-looking statements address future results, events and

conditions, they, by their very nature, involve inherent risks and uncertainties, many of which are unforeseeable and beyond the company’s control. Such known and

unknown risks, uncertainties and other factors may cause actual results, performance or other

achievements to differ materially from the anticipated results, performance or achievements

expressed, projected or implied by these forward-looking statements. These factors, some of which are discussed under “Risk Factors” in Section 3 of the Form

20-F filed with the Securities and Exchange Commission on 26 June 2014, include, but are not

limited to: all matters relating to or arising out of the prior manufacture of products that

contained asbestos by current and former James Hardie subsidiaries; required contributions to AICF, any shortfall in AICF and the effect of currency exchange rate

movements on the amount recorded in the company’s financial statements as an asbestos liability;

governmental loan facility to AICF; compliance with and changes in tax laws and treatments;

competition and product pricing in the markets in which the company operates; the consequences of product failures or defects; exposure to environmental,

asbestos, putative consumer class action or other legal proceedings; general economic and market

conditions; the supply and cost of raw materials; possible increases in competition and the

potential that competitors could copy the company’s products; reliance on a small number of customers; a customer’s inability to pay; compliance with and

changes in environmental and health and safety laws; risks of conducting business internationally;

compliance with and changes in laws and regulations; the effect of the transfer of the

company’s corporate domicile from The Netherlands to Ireland, including changes in corporate governance and any potential tax benefits related thereto; currency

exchange risks; dependence on customer preference and the concentration of the company’s customer

base on large format retail customers, distributors and dealers; dependence on residential and

commercial construction markets; the effect of adverse changes in climate or weather patterns; possible inability to renew credit facilities on

terms favourable to the company, or at all; acquisition or sale of businesses and business segments;

changes in the company’s key management personnel; inherent limitations on internal

controls; use of accounting estimates; and all other risks identified in the company’s reports filed with Australian, Irish and US securities agencies and exchanges (as

appropriate). The company cautions you that the foregoing list of factors is not exhaustive and that

other risks and uncertainties may cause actual results to differ materially from those

referenced in the company’s forward-looking statements. Forward-looking statements speak only as of the date they are made and are statements of the company’s

current expectations concerning future results, events and conditions. The company assumes no

obligation to update any forward-looking statements or information except as required by

law. |

•

BACKGROUND

•

CAPACITY DIRECTIONAL CONCEPTS

–

LOGIC

–

CURRENT PLAN AND FORECAST

–

NEXT STATE OF MANUFACTURING

•

TACTICAL REVIEW OF CAPITAL PROJECT

AGENDA / KEY TAKE AWAYS

4 |

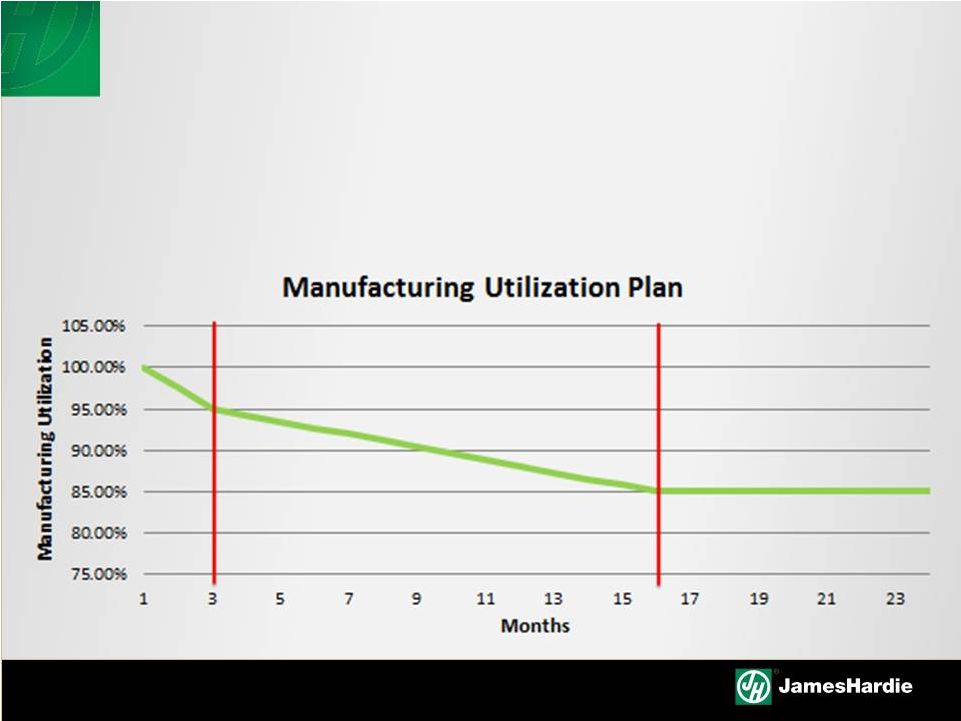

Utilization concept allows for both a short and long term sheet

machine

start

up

capacity

decision

while

allowing

flexibility

to

act

accordingly inside the network.

CAPACITY UTILIZATION LOGIC –

85% OR 95%

5 |

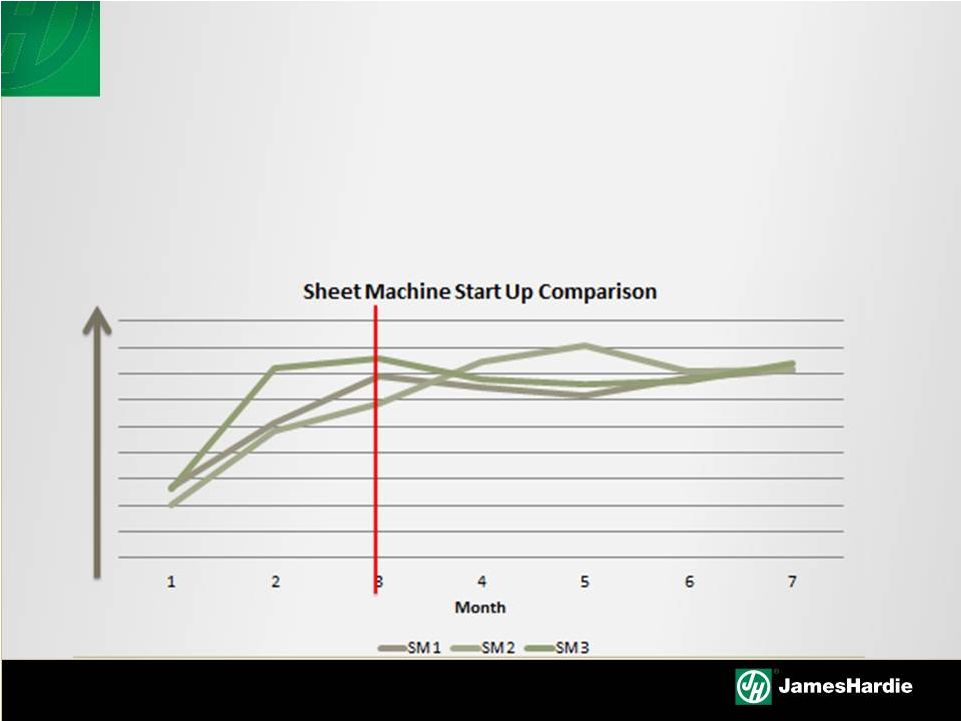

95% Plan –

3 to 6 Months out (Short Term)

•

•

CAPACITY UTILIZATION LOGIC –

85% OR 95%

6

History / Experience on ramp up and utilization

Ramp up effects design and utilization needs |

85% Plan –

16 + Months out (Long Term)

•

•

CAPACITY UTILIZATION LOGIC –

85% OR 95%

Start Construction

Start Up

Ramp Up

7

History of Growth

Risk adverse –

Be early rather than late |

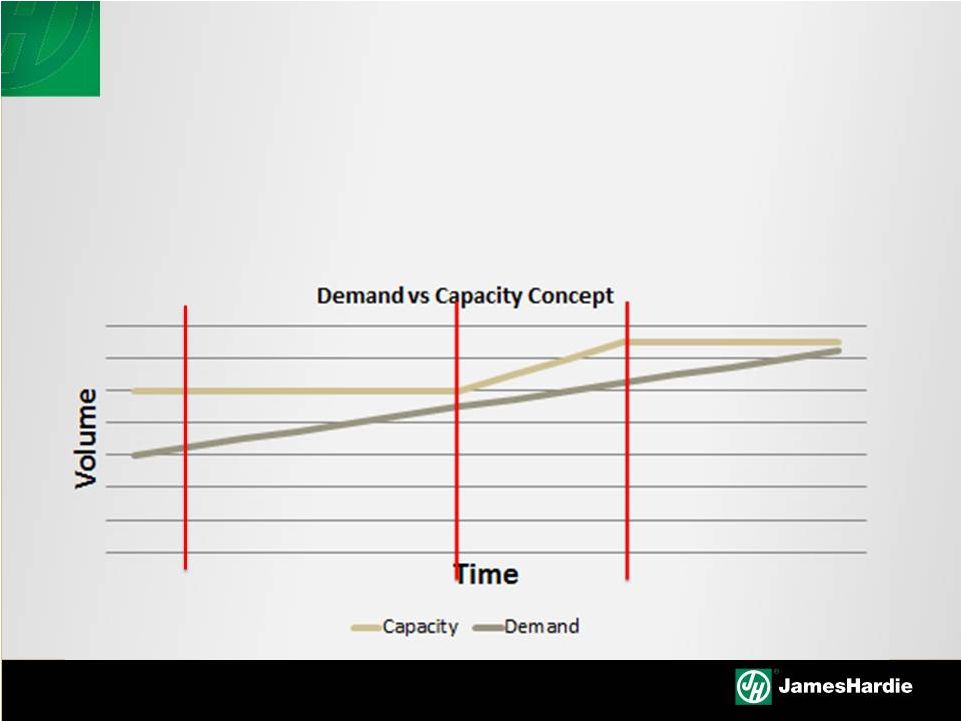

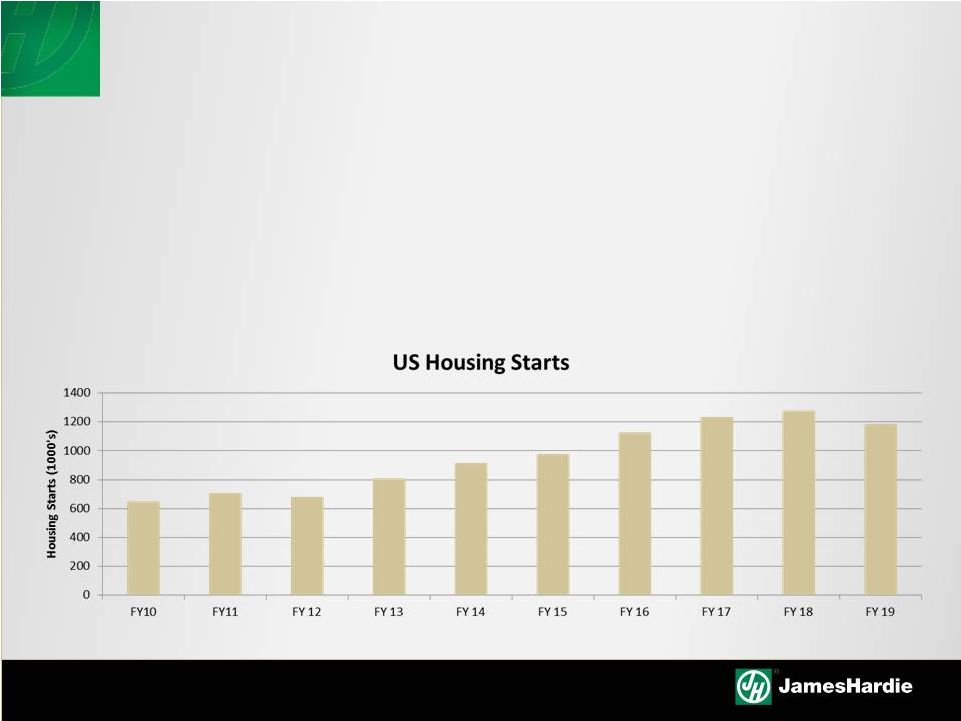

•

Two Key Inputs to Plan

•

James Hardie Growth

–

R&R Growth Rate

–

New Construction Starts

–

James Hardie Market Growth

•

Results

–

US house starts behind plan

–

James Hardie Market Growth at plan

CAPACITY PLANNING LOGIC –

LONG TERM

Dodge New Construction Forecast FY14 –

FY19

8 |

•

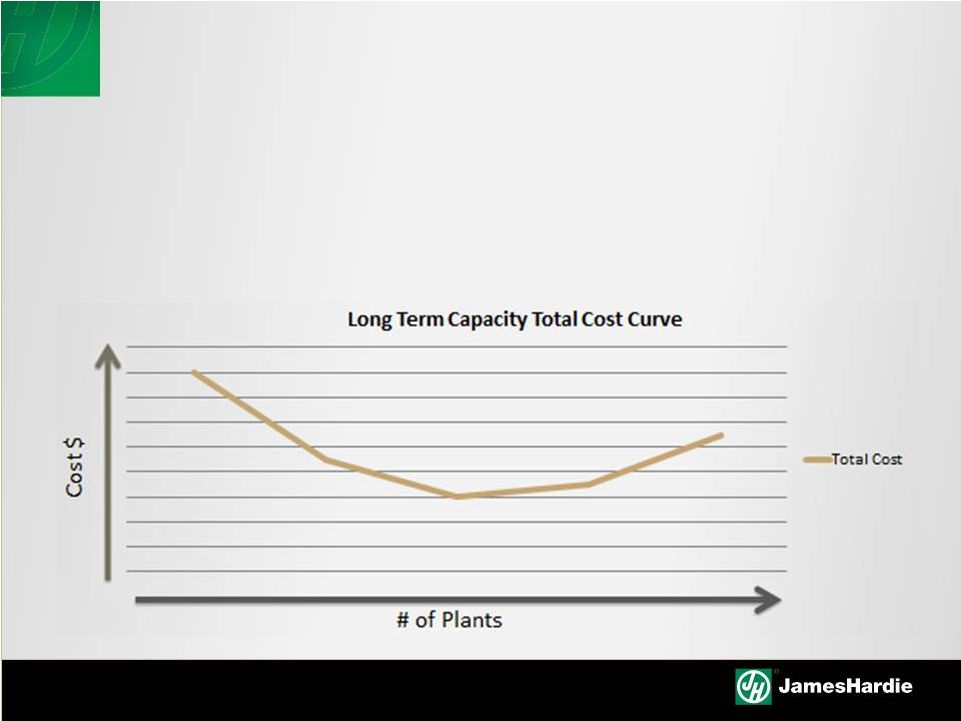

Determines Ideal # of plants

•

Long Term Cost curve =

+

Fixed

+

Freight

+

Capital

+

Inventory

CAPACITY PLANNING LOGIC

•

Inflection point indicates total # of

plants

–

New Additions

•

Summerville

•

Tacoma

•

Green Fields

9 |

•

BACKGROUND

•

CAPACITY DIRECTIONAL CONCEPTS

–

LOGIC

–

CURRENT PLAN AND FORECAST

–

NEXT STATE OF MANUFACTURING

•

TACTICAL REVIEW OF CAPITAL PROJECT

AGENDA / KEY TAKE AWAYS

10 |

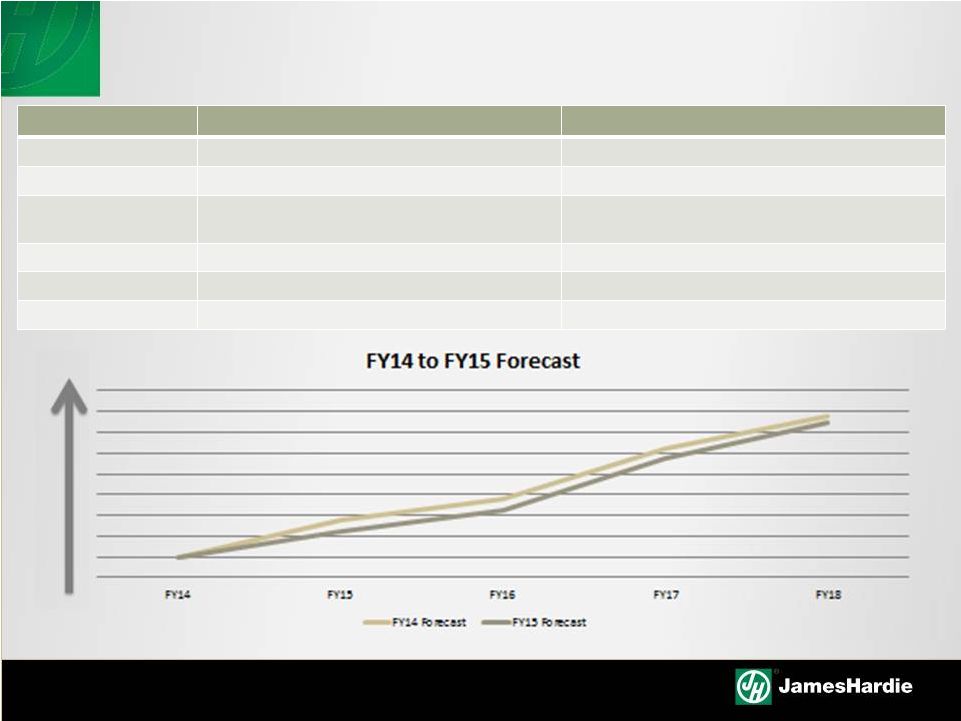

CAPACITY PLAN FY14 AND FY15 GUIDANCE

FY14 PLAN

FY15 Difference to Plan

FY 14

No Additional Capacity

Started Up SM1 Wax

FY 15

Fontana SM1/SM2 and Cleburne

Only need SM2 Fontana

FY16

Cleburne SM3 and PC SM 4 and Trim AC

Cleburne Start Up Dependent on Demand

Schedule

FY17

Tacoma SM2 and Summerville SM1

Tacoma Start Up Dependent on Demand Schedule

FY18

Green Field Capacity

Green Field delayed

FY19

No Guidance

11 |

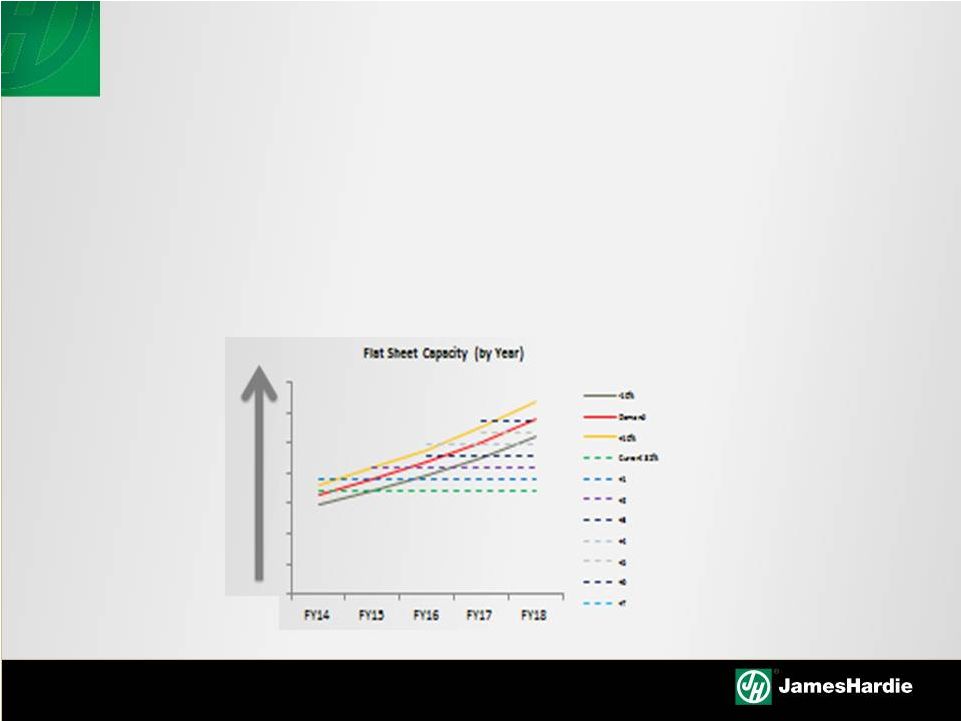

CAPACITY SENSITIVITY

•

Evaluated demand plan with range of ±10%

–

Capacity changes are not influenced by small demand swings

–

Lower demand pushes out 1 yr

–

Higher demand pulls decisions sooner or run above utilization

target

12 |

CAPACITY EFFICIENCY

Capital $ / Square Feet Produced

•

•

•

Revenue and/or Margin vs Capital $

•

•

13

Good measurement for plank and panel line

Good measurement of Green Field vs Brown Field.

Poor Measurement of specialty products impact on

both capital cost and revenue

Takes into account the impact of higher sales price

for specialty products

Highlights the cost of capital for these specialty products

|

CAPACITY CONCEPTS SUMMARY

•

Planning is a sliding scale

•

Capacity additions are more weighted today

toward specialty products

•

Capacity additions leads us to optimization to

ensure return on investment

14 |

•

BACKGROUND

•

CAPACITY DIRECTIONAL CONCEPTS

–

LOGIC

–

CURRENT PLAN AND FORECAST

–

NEXT STATE OF MANUFACTURING

•

TACTICAL REVIEW OF CAPITAL PROJECT

AGENDA / KEY TAKE AWAYS

15 |

NEXT

STATE OF MANUFACTURING Optimization of capital cost

•

Governmental Influences : Water, Air, Building

•

Current Non Compressible Influences : Water

Discharge, Curing, Raw Materials,

•

Current Compressible Influences : Machine output,

building utilization/line design, labor utilization

16 |

NEXT

STATE OF MANUFACTURING Plant 1

Plant 2

Edge Treatment

Yes

Yes

Top Treatment

Yes

No

Coating Process

1 Coater

2 Coaters

Drying Process

1 Dryer

2 Dryers

Automatic On Loader

Yes

No

Sealers

No

Yes

Building Space (ft^2)

30,000

100,000

# Critical Pieces of Equipment

7

11

Example of Line Design, Building Utilization, Machine output

17 |

•

BACKGROUND

•

CAPACITY DIRECTIONAL CONCEPTS

–

LOGIC

–

CURRENT PLAN AND FORECAST

–

NEXT STATE OF MANUFACTURING

•

TACTICAL REVIEW OF CAPITAL PROJECT

AGENDA / KEY TAKE AWAYS

18 |

CAPACITY UPDATE

Capacity expansion plans aligned to current forecast and

our target utilization rate

–

Fontana:

Ramp-up

currently

on

track

–

Plant

City

Trim:

Construction

complete

Q4FY15

–

Cleburne:

Construction

complete

Q1FY16

–

Next

Capacity

Addition:

–

Summerville

FY17

–

Future

Capacity

Additions:

–

Tacoma

and

Green

Field

19 |

•

Capacity planning is sliding scale relative to market and share growth but

base thought process is the same.

•

The forecast has been reduced in response to slower than expected US

housing recovery

•

Capacity headwinds:

–

Construction cost increase –

offset partially by Brown Field, and

Design efficiency

–

Permitting –

Air, Construction and Water

•

Current capacity additions on track to meet scope and utilization criteria

SUMMARY

20 |

QUESTIONS |