R&D OVERVIEW

Michael Benjamin

24 September 2014

Exhibit 99.4 |

R&D OVERVIEW

Michael Benjamin

24 September 2014

Exhibit 99.4 |

DISCLAIMER

2

This Management Presentation contains forward-looking statements. James Hardie may from time to

time make forward-looking statements in its periodic reports filed with or furnished to the

SEC, on Forms 20-F and 6-K, in its annual reports to shareholders, in offering circulars, invitation memoranda and prospectuses, in media releases and other written

materials and in oral statements made by the company’s officers, directors or employees to

analysts, institutional investors, existing and potential lenders, representatives of the media

and others. Statements that are not historical facts are forward-looking statements and such

forward-looking statements are statements made pursuant to the Safe Harbor Provisions of

the Private Securities Litigation Reform Act of 1995.

Examples of forward-looking statements include: •

statements about the company’s future performance; •

projections of the company’s results of operations or financial condition; •

statements regarding the company’s plans, objectives or goals, including those relating to

strategies, initiatives, competition, acquisitions, dispositions and/or its products;

•

expectations concerning the costs associated with the suspension or closure of operations at any of

the company’s plants and future plans with respect to any such plants;

•

expectations concerning the costs associated with the significant capital expenditure projects at any

of the company’s plants and future plans with respect to any such projects;

•

expectations regarding the extension or renewal of the company’s credit facilities including

changes to terms, covenants or ratios;

•

expectations concerning dividend payments and share buy-backs; •

statements concerning the company’s corporate and tax domiciles and structures and potential

changes to them, including potential tax charges;

•

statements regarding tax liabilities and related audits, reviews and proceedings; •

statements regarding the possible consequences and/or potential outcome of the legal proceedings

brought against two of the company’s subsidiaries by the New Zealand Ministry of Education

and the potential product liabilities, if any, associated with such proceedings;

•

expectations about the timing and amount of contributions to Asbestos Injuries Compensation Fund

(AICF), a special purpose fund for the compensation of proven Australian asbestos-related

personal injury and death claims;

•

expectations concerning indemnification obligations; •

expectations concerning the adequacy of the company’s warranty provisions and estimates for

future warranty-related costs;

•

statements regarding the company’s ability to manage legal and regulatory matters (including but

not limited to product liability, environmental, intellectual property and competition law

matters) and to resolve any such pending legal and regulatory matters within current estimates and in anticipation of certain third-party recoveries; and

•

statements about economic conditions, such as changes in the US economic or housing recovery or

changes in the market conditions in the Asia Pacific region, the levels of new home

construction and home renovations, unemployment levels, changes in consumer income, changes or stability in housing values, the availability of mortgages and

other financing, mortgage and other interest rates, housing affordability and supply, the levels of

foreclosures and home resales, currency exchange rates, and builder and consumer confidence. |

3

Words such as “believe,” “anticipate,” “plan,” “expect,”

“intend,” “target,” “estimate,” “project,” “predict,” “forecast,” “guideline,” “aim,” “will,” “should,” “likely,” “continue,”

“may,” “objective,” “outlook” and similar expressions are

intended to identify forward-looking statements but are not the exclusive means of identifying such statements. Readers are cautioned

not to place undue reliance on these forward-looking statements and all such forward-looking

statements are qualified in their entirety by reference to the following cautionary statements.

Forward-looking statements are based on the company’s current expectations, estimates and

assumptions and because forward-looking statements address future results, events and

conditions, they, by their very nature, involve inherent risks and uncertainties, many of which are

unforeseeable and beyond the company’s control. Such known and unknown risks,

uncertainties and other factors may cause actual results, performance or other achievements to differ

materially from the anticipated results, performance or achievements expressed, projected or

implied by these forward-looking statements. These factors, some of which are discussed under “Risk Factors” in Section 3 of the Form 20-F filed with the Securities and

Exchange Commission on 26 June 2014, include, but are not limited to: all matters relating to or

arising out of the prior manufacture of products that contained asbestos by current and former

James Hardie subsidiaries; required contributions to AICF, any shortfall in AICF and the effect of currency exchange rate movements on the amount recorded in the company’s

financial statements as an asbestos liability; governmental loan facility to AICF; compliance with and

changes in tax laws and treatments; competition and product pricing in the markets in which the

company operates; the consequences of product failures or defects; exposure to environmental, asbestos, putative consumer class action or other legal

proceedings; general economic and market conditions; the supply and cost of raw materials; possible

increases in competition and the potential that competitors could copy the company’s

products; reliance on a small number of customers; a customer’s inability to pay; compliance with and changes in environmental and health and safety laws; risks of

conducting business internationally; compliance with and changes in laws and regulations; the effect

of the transfer of the company’s corporate domicile from The Netherlands to Ireland,

including changes in corporate governance and any potential tax benefits related thereto; currency exchange risks; dependence on customer preference and the concentration

of the company’s customer base on large format retail customers, distributors and dealers;

dependence on residential and commercial construction markets; the effect of adverse changes in

climate or weather patterns; possible inability to renew credit facilities on terms favourable to the company, or at all; acquisition or sale of businesses and business

segments; changes in the company’s key management personnel; inherent limitations on internal

controls; use of accounting estimates; and all other risks identified in the company’s

reports filed with Australian, Irish and US securities agencies and exchanges (as appropriate). The

company cautions you that the foregoing list of factors is not exhaustive and that other risks

and uncertainties may cause actual results to differ materially from those referenced in the company’s forward-looking statements. Forward-looking statements speak only

as of the date they are made and are statements of the company’s current expectations concerning

future results, events and conditions. The company assumes no obligation to update any

forward-looking statements or information except as required by law. |

BACKGROUND

4

Michael Benjamin, Director, R&D

11+ years in James Hardie USA

4 years in R&D Chicago

•

ColorPlus R&D Manager

•

Non-FC R&D Manager

•

Product Development

•

Technology Implementation

6 years in R&D Fontana

•

US R&D Director

•

Role includes R&D, Engineering

and Claims Management

1+ year in R&D Fontana |

•

R&D Strategy

•

R&D Overview

–

Dynamic Capability

–

FC Centric Focus

–

JH Business Impact

•

Key Takeaways / Summary

•

Questions

PRESENTATION AGENDA

5 |

Enable James Hardie Product Leadership Strategy

TECHNOLOGY STRATEGY

6

•

Provide a continuous pipeline of innovative new products and

technologies with sustainable advantages to achieve our

category and market share goals

•

Our role is to act as the technology pipeline for the organization

|

R&D OVERVIEW

JH Business Impact

7

Focus

Results

Capability

JH R&D’s Key Strengths

Dynamic Capability

Evolves

further

–

technology

advantage

FC Centric Focus

People

Execution |

DYNAMIC CAPABILITY

R&D Overview

JH Business

Impact

Focus

Capability |

Fontana, CA

Naperville, IL

Sydney, NSW

R&D LOCATIONS

9

Three

research

centers

–

US

and

Australia

•

Fontana, CA

•

Naperville, IL

•

Sydney, NSW |

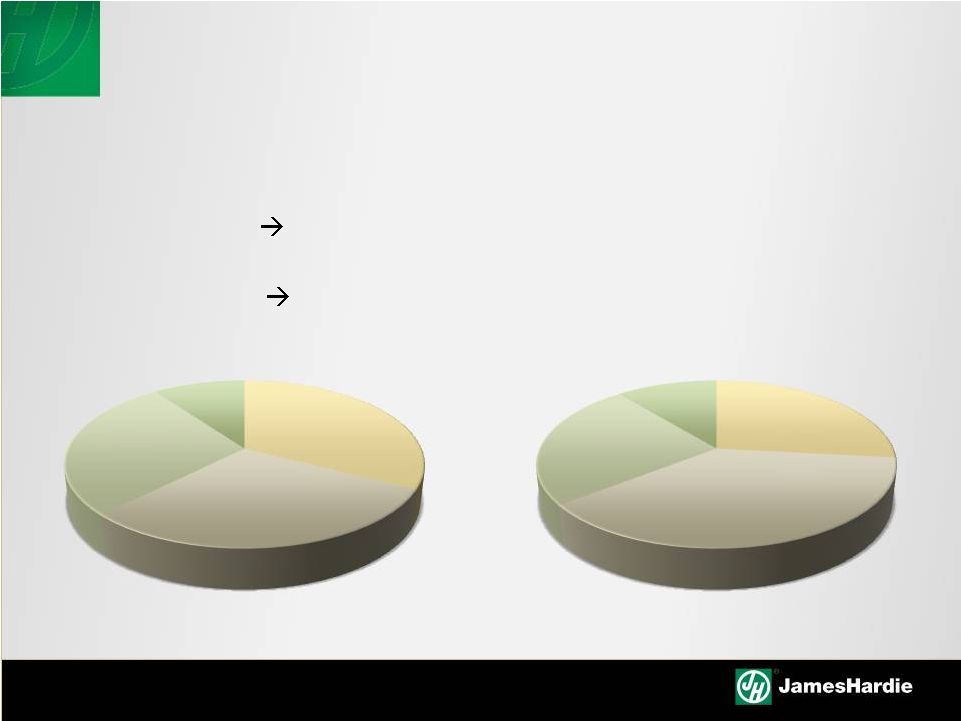

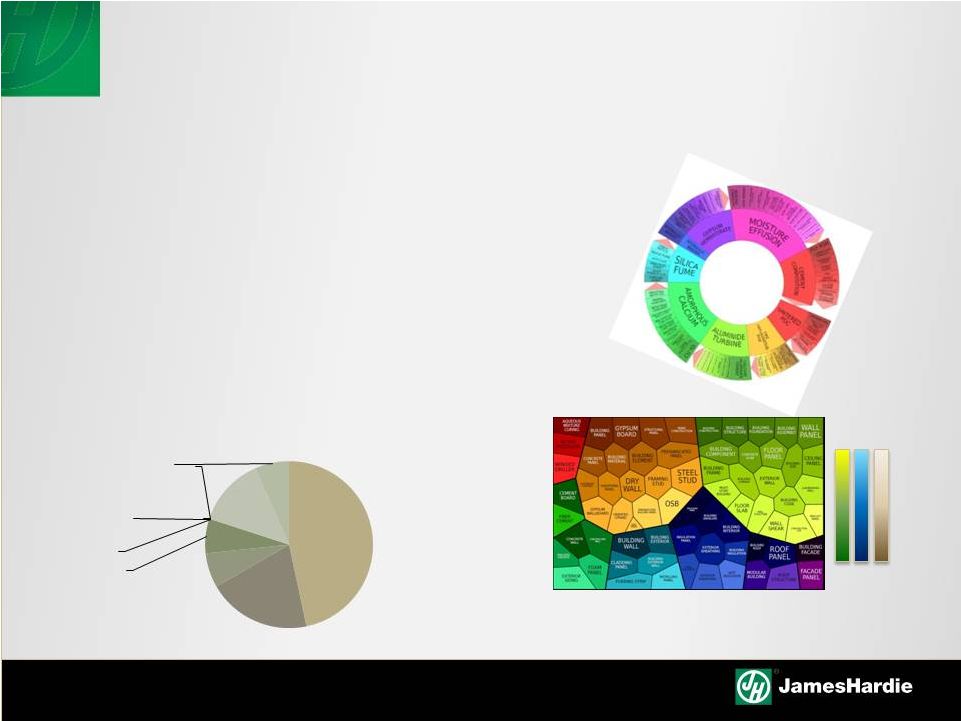

Diverse workforce of 130+ technologists

•

Scientists

Chemistry, Materials, Inorganic, Composite, Wood

& Fibers and Building Science

•

Engineers

Chemical, Mechanical, Electrical, Civil and

Environmental

R&D RESOURCES

~60% have PhD or Master’s Degree

~70% with greater than 6 years service

10

Bachelor's

32%

Master's

30%

PhD's

28%

Others

10%

0-5 Yrs

27%

6-10 Yrs

37%

11-15 Yrs

25%

16+ Yrs

11% |

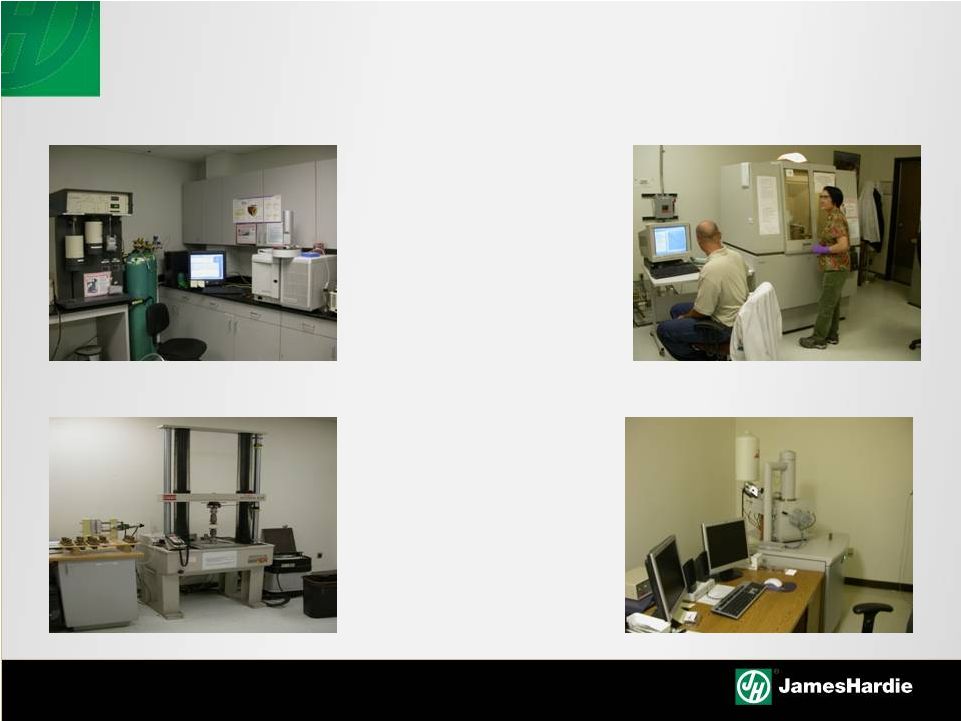

RESEARCH CAPABILITIES

Thermal

Properties

Compositional

Analysis

Mechanical

Properties

Microscopy

11 |

RESEARCH CAPABILITIES

Longer-Term,

Real-Life

Exposure

12 |

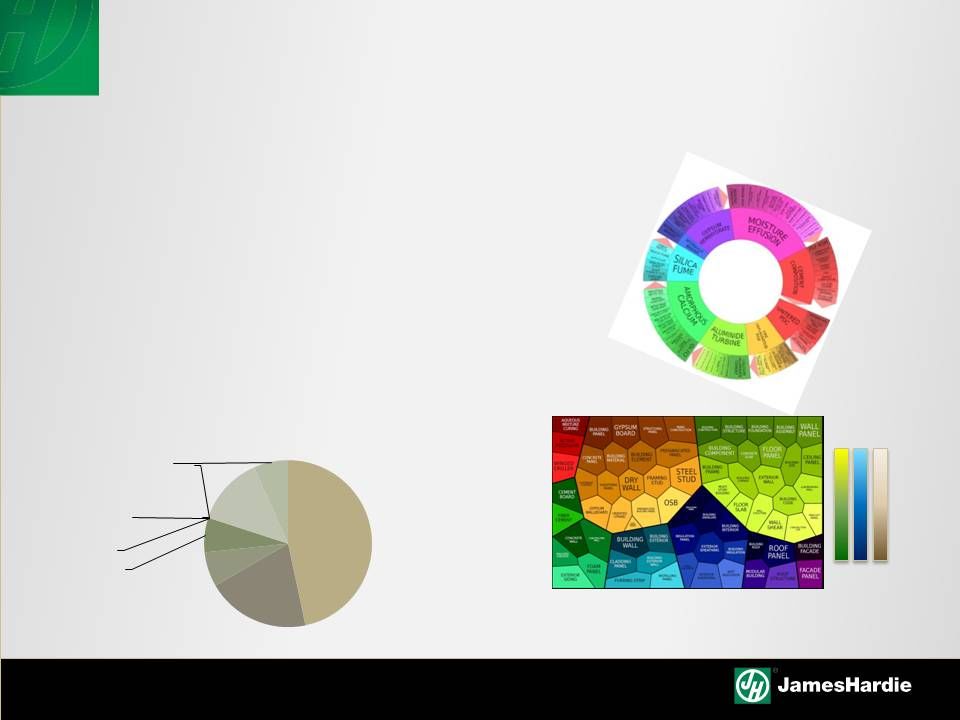

Innovation tools

•

3D printing prototypes (Faster concepts)

•

Pilot processes (Concept investment)

Intellectual property

•

Idea generation process

•

Focused approach on opportunities

INNOVATION CAPABILITY

13

IP Tools (IP Space Availability)

Crowded

IP Space

IP Space

Available

All FC siding

Coatings

Durability

NT3

Tech

Hatscheck

0%

LDA

0%

Non FC

0%

Tools &

0%

New Platforms

New Tech

FY15 IP Concepts YTD

Accessories |

Chicago R&D is operational from Q4

FY13, focusing mainly on non–FC

development

•

Product Development

•

Non-FC materials characterization

•

Product and system testing

•

Pilot lines

Currently capable to develop and

implement non-FC technology initiatives

aligned with business needs

NON–FC CAPABILITY

14 |

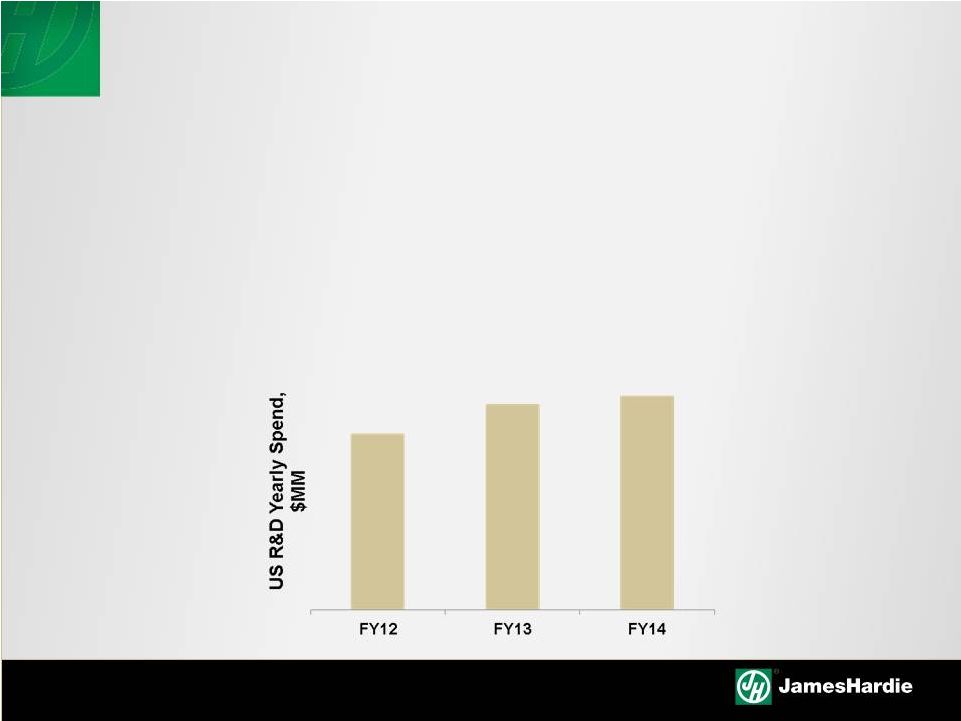

R&D yearly spend is divided between research

and development projects

Research

–

Core

understanding

of

technologies

and

science

behind

them

Development

–

Focus

around

implementing

new

technology

and

new

products

R&D SPEND

15 |

FC

CENTRIC FOCUS R&D Overview

JH Business

Impact

Focus

Capability |

Enable

effective development and implementation of key initiatives Ensure continuous

pipeline of new concepts and ideas JH INNOVATION PROCESS

17

Decision to

Develop

Decision to

Implement

Transfer to

BAU

Feasibility

Development

Implementation

Post

Implementation

What Problem is this

Solving?

Feedback

Loop

Business

Need

Business

Strategy |

FC

STRATEGIC PRIORITIES 18

Product

Performance

New Product

Development

Platform

Development

Technical Support

•

Substrate Development

•

Coatings Development

•

Raw Materials Formulation

•

Test Method Development

•

Trim/Shapes

•

ColorPlus®

Development

•

Reveal®

•

Top of the Market Products

•

Foam-back Plank

•

Product Form

•

Product Aesthetics

•

Advanced Finishing

•

Concealed Fastening

•

Best Practices/Install

•

Raw Material Sourcing

•

Manufacturing Process Optimization

•

Yield Improvements

ENABLERS |

Multi-faceted approach to product performance

PRODUCT PERFORMANCE APPROACH

19

Product Performance

•

Material

Composition

•

Product

Formation

•

Raw Material

Selection

•

Raw Material

Interaction

•

Primers

•

Top Coat

Formulation

Substrate

Coatings |

Raw

material research is an important aspect of product performance and technical

support strategies Enhance product performance

•

Raw material selection

•

Formulations

Technical support

•

Secure

supply

–

pulp,

cement,

silica

et

al.,

-

Raw material sourcing / New formulations

•

Ensure quality

-

Consistent supply / Universal specifications

•

Improve utilization

RAW MATERIAL FOCUS

20 |

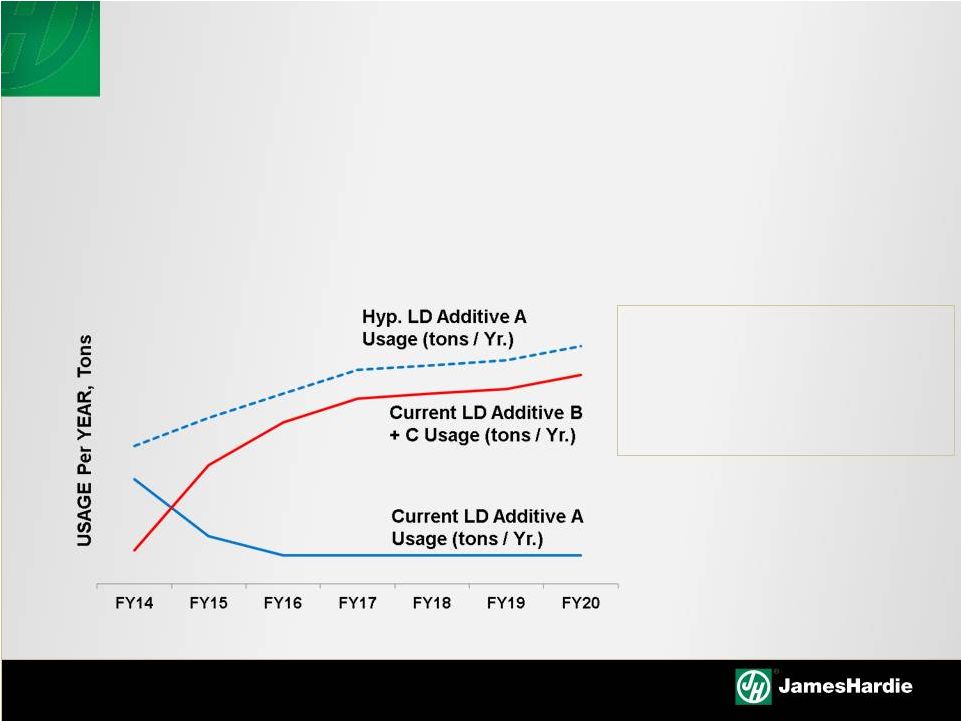

James Hardie uses low density functional additives for:

•

Lighter / Thicker products

•

Ease of use

•

Performance

Our strategy is to reduce dependency on commercial additives to

in-house technology substitutes

LOW DENSITY ADDITIVES

21

Interiors

Exteriors

HZ10®

Siding

Exteriors

HZ5®

Siding

Low

Density

(LD)

LD

Options

LD

Additive

A

LD

Additive

D

LD

Additive

C

LD

Additive

B |

Invest in new manufacturing platforms to enable step-

change products in current or new category

PLATFORM DEVELOPMENT FOCUS

22

Platform A

(Current)

Plank

/ Panel

Flat sheets

Higher

throughput

Platform B

(Current)

Thicker

products

Functional

Platform C

(New)

Aesthetics

Product

Form

High-end

products

Platform D

(New)

Shapes

Extreme

applications

Functional |

Balanced mix of step change products and product line

extensions to drive JH category and market share growth

PRODUCT DEVELOPMENT FOCUS

23

Form

Aesthetics

Texture

Shape

Weight

Color

Function

Water

management

Durability

Energy

efficiency

Concealed

fastening

Nail line

Ease of

install

Features |

Evaluate and develop non–FC technologies for fit with

current and future JH business

Mouldings

–

Provide shapes to complement JH FC trim portfolio

Windows

–

Develop non-FC technology as an entry vehicle into

NON–FC STRATEGIC PRIORITIES

24

fiber glass windows |

JH

BUSINESS IMPACT R&D Overview

JH Business

Impact

Focus

Capability |

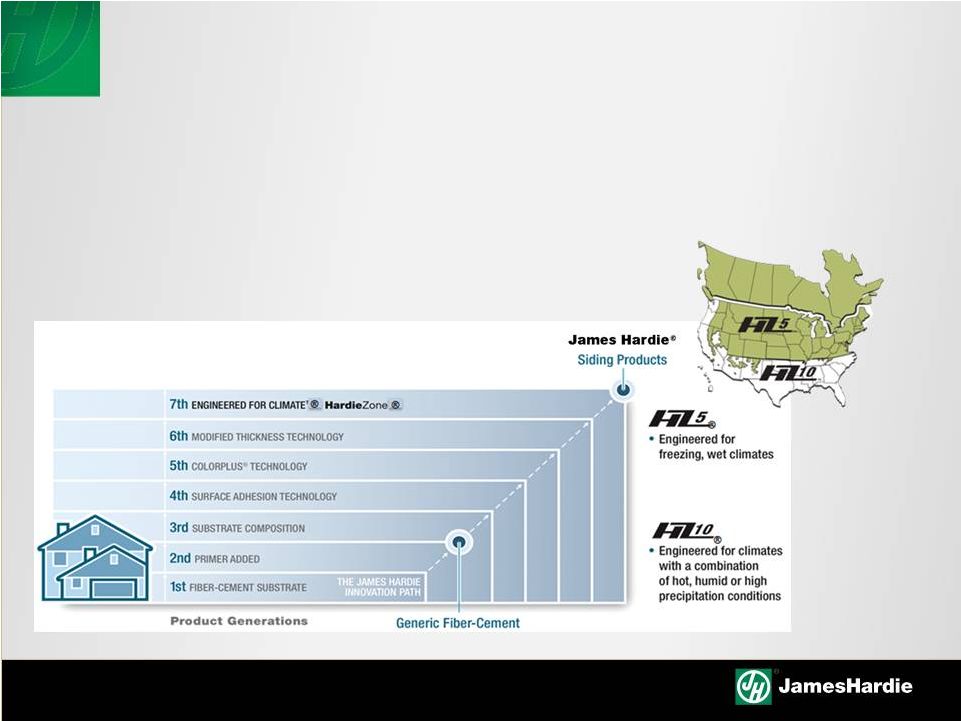

Delivered HardieZone

®

Engineered for Climate

®

Products

7

th

Generation of FC products

HARDIEZONE

®

–

ENGINEERED

FOR

CLIMATE

®

26 |

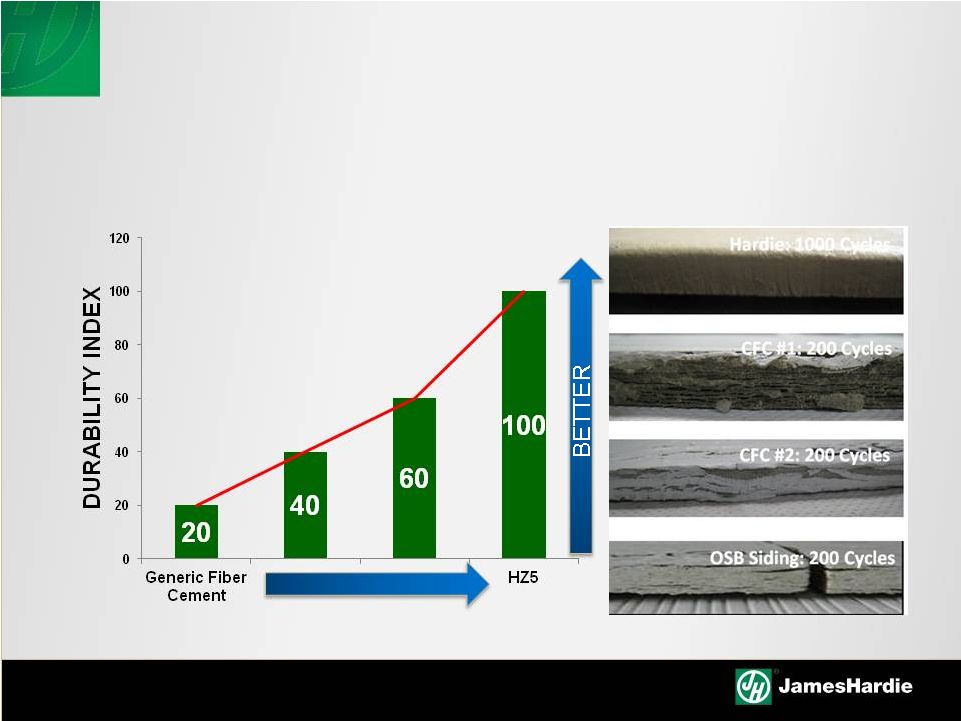

HZ5

®

siding performs 5x better than generic FC in system testing

PRODUCT PERFORMANCE

27

Source: James Hardie Internal Research and Testing

TIME |

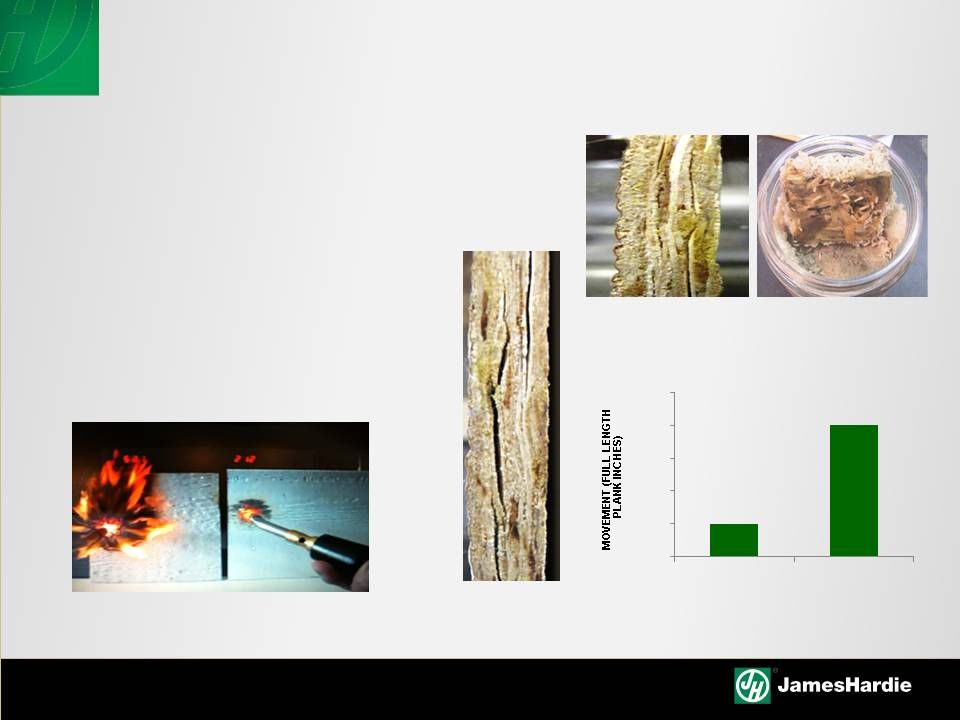

JH vs.

COMPETITORS (OSB / Hardboard) 28

Like Hardboard, OSB siding is a wood based,

manufactured product that can experience similar

issues when exposed in external applications :

Source: James Hardie Internal Research and Testing

Termite Activity

Splitting

Fire

Mold Growth

Moisture Movement

JH

OSB

1/16

1/4

0

1/16

1/8

3/16

1/4

5/16

JH

OSB

Real World Movement

is 4X, Damp to Ambient

•

Fire

•

Splitting

•

Mold Growth

•

Termites

•

Significant Moisture Movement

•

Swelling |

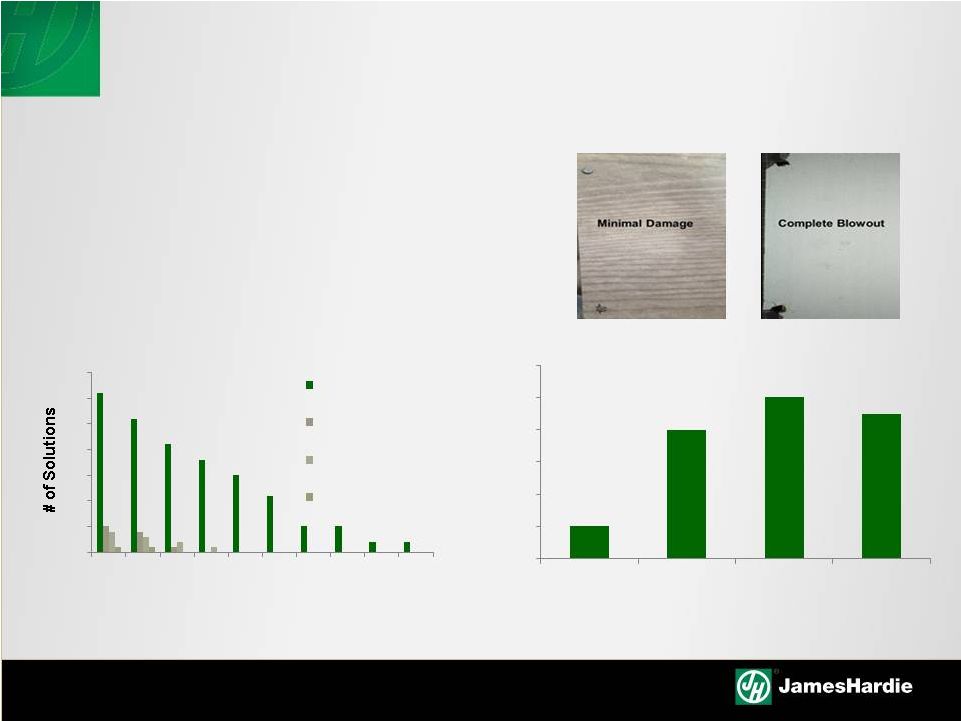

JH

vs. COMPETITORS (CFC) 29

Competitive Fiber Cement Siding

Source: James Hardie Internal Research and Testing

JH

CFC

Nailing

Brittleness (Lower the Better)

Source: External Code Compliance Reports (ICC-ES)

0

5

10

15

20

25

30

35

110

120

130

140

150

160

170

180

190

200

Wind Speed (mph)

# Blind Nail Solutions

(Exp. Cat D @ 30ft.)

HardiePlank®

Siding

CFC #1

CFC #2

CFC #3

0

1

2

3

4

5

6

JH

CFC #1

CFC #2

CFC #3

•

Low quality raw materials

•

More brittle, nailing damage

•

Few approved wind load solutions

•

High movement (moisture)

•

Poor paint and primer adhesion |

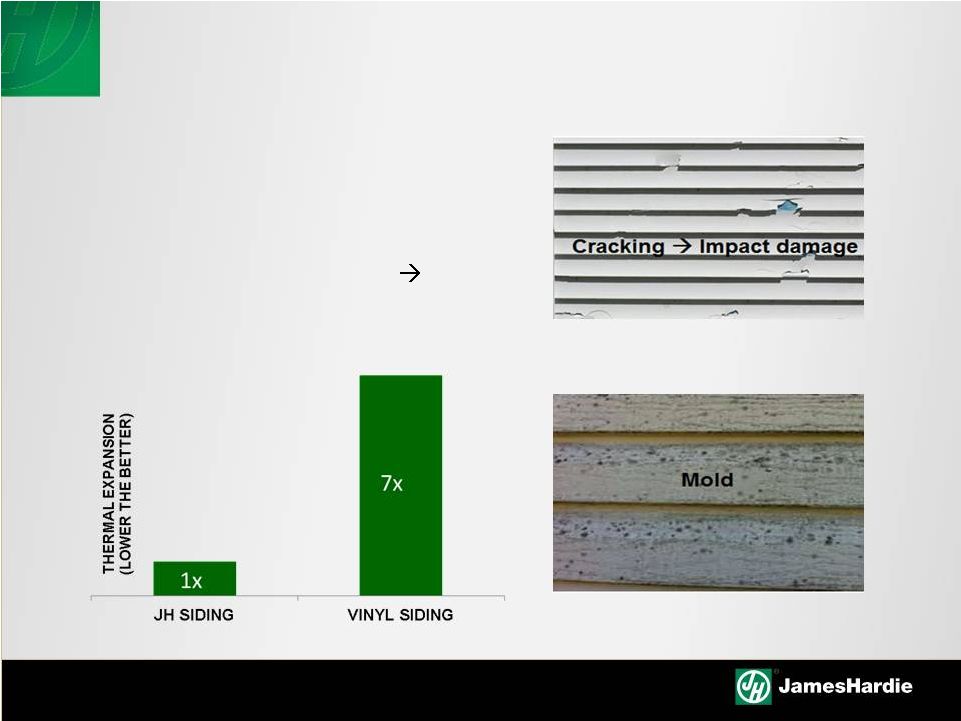

JH

vs. COMPETITORS (Vinyl) 30

Vinyl / PVC Siding

Source: James Hardie Internal Research and Testing

•

Looks cheap

•

Relatively durable but can melt even

from reflected light (low-e window)

•

Very high thermal movement

7x

compared to JH

•

Poor impact resistance |

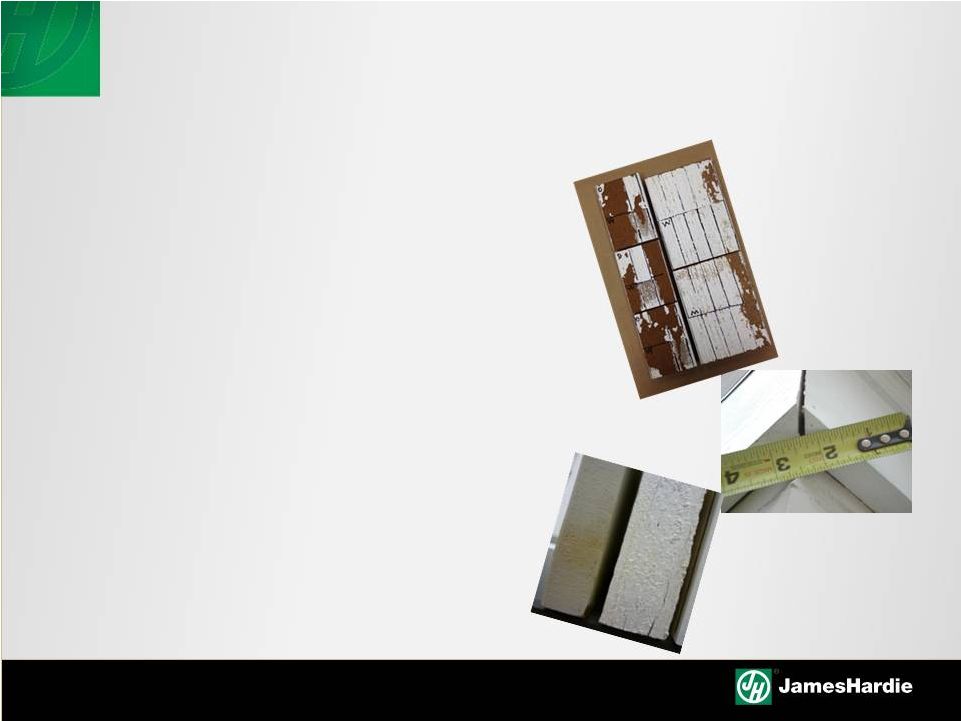

•

OSB / Hardboard trim

•

Poor paint adhesion

•

Low resistance to mold

•

High water absorption and swelling

•

PVC trim

•

High thermal expansion (7x)

•

High movement / High gapping

•

Low thermal stability / Yellowing

•

Polyurethane composite trim

•

High thermal expansion (3x)

•

Low UV resistance (PU)

•

Poor paint adhesion

JH vs. COMPETITORS (Trim)

31

Paint Adhesion –

OSB / Hardboard

Gapping -

PVC

Swelling –

OSB /

Hardboard

Source: James Hardie Internal Research and Testing |

By

focusing on low density research, JH was able to reduce the dependency on

commercial additives to in-house technology substitutes

LOW DENSITY ADDITIVES

32

This Enables:

•

Lighter / Thicker products

•

Cost –

effective, Durable products

•

Reliable supply of raw material |

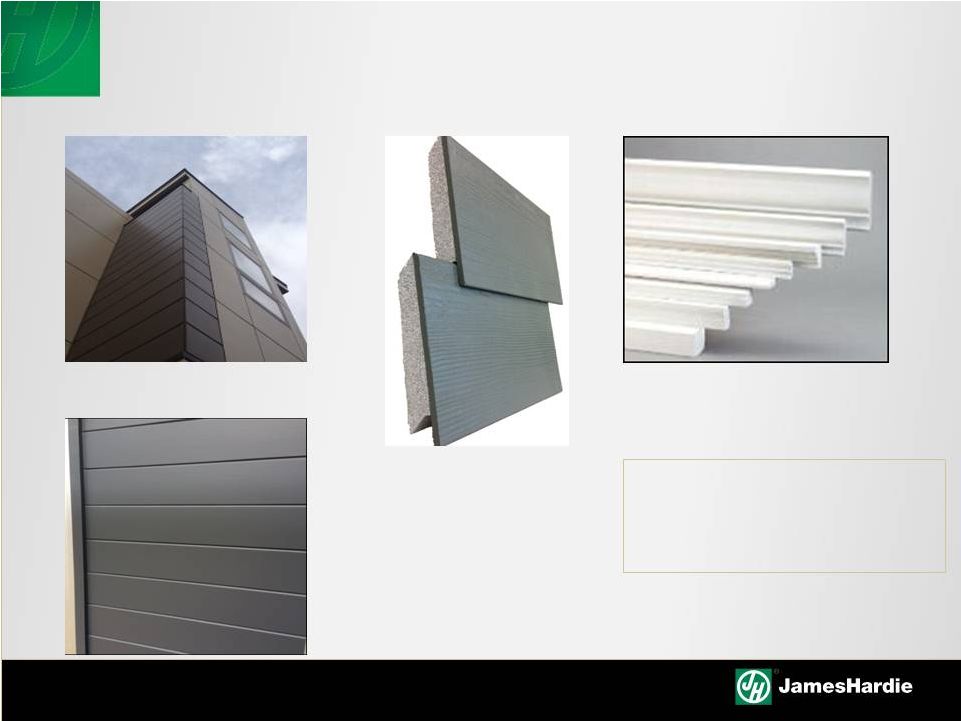

PRODUCT DEVELOPMENT

33

Other Products

•

Trim extensions

•

Shingle extensions

•

High-end panel extensions

HardieReveal2.0™Panel

System

HardiePlank® Lap

Siding with Insulation

HardieTrim™ Mouldings

Artisan® V-Rustic

Siding |

In

summary, JH R&D has enabled •

Impact on product performance

•

Product leadership compared to competitors

•

Impact on raw materials and low density materials

•

Product and platform development

•

Better innovation

STRONG JH BUSINESS IMPACT

34 |

SUMMARY

R&D Overview

JH Business

Impact

Focus

Capability |

KEY

TAKEAWAYS James Hardie R&D invests and functions towards:

Ensuring Product Performance

•

JH products demonstrate superior durability compared to the

competition

Maintaining Product Leadership

•

Differentiated products are being created to enable future PDG vs.

wood and vinyl options

Enabling Platforms

•

New platforms are being developed to enable future business growth

36 |

R&D FUTURE DELIVERABLES

Continue Research and Development of Key Technology Strategies

•

Product Performance

•

Raw Materials

•

Low Density

Continue Investments of Key Platform Strategies

Continue to Deliver New Products

Aligned with Corporate Strategy

•

Act

as

the

technology

pipeline

for

JH

and

deliver

key

results

towards

JH’s overall category and market share growth strategy

37 |

QUESTIONS

R&D Overview

JH Business

Impact

Focus

Capability |