Exhibit 99.8

THROUGH OUR INVESTMENT IN

ADDITIONAL MANUFACTURING

CAPACITY, IN RESEARCH AND

DEVELOPMENT, AND IN OUR

ORGANISATIONAL CAPABILITY WE

ARE CEMENTING JAMES HARDIE’S

POSITION AS A LEADER IN THE

BUILDING MATERIALS INDUSTRY

CHAIRMAN’S

REPORT

UNDER THE LEADERSHIP

OF THE MANAGEMENT TEAM

AND THROUGH THE COMMITMENT

OF ALL EMPLOYEES, JAMES

HARDIE DELIVERED STRONG

FINANCIAL RESULTS IN

FISCAL YEAR 2015

With our focus on growing market demand, continued commitment to the expansion of our manufacturing capacity and

overall enhancement of our organisational capabilities, we believe we are well positioned to take advantage of the expected strengthening of the US housing market and to continue to deliver growth and superior returns over the long-term.

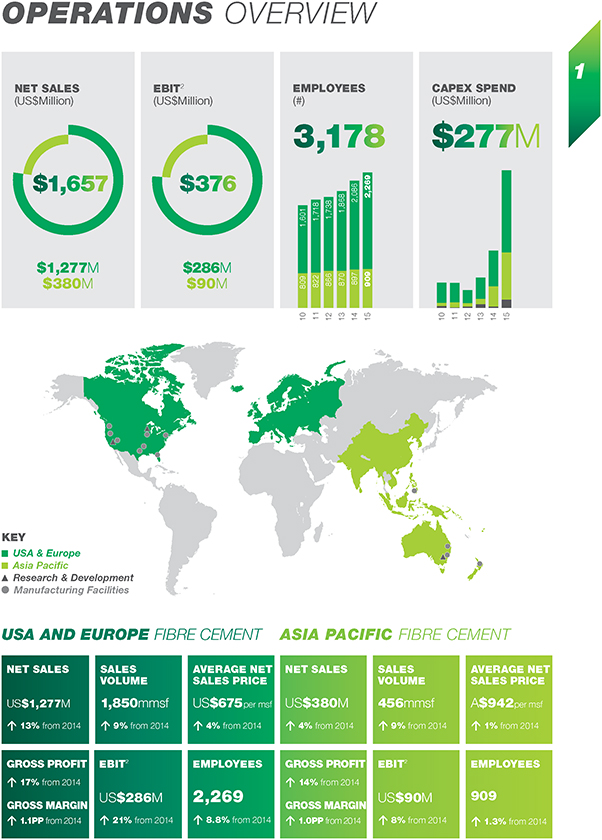

In the US the higher sales volumes were driven by market share gains and the continued modest recovery in the underlying US housing market. The business also benefitted

from a higher average sales price, a vigilant focus on costs and an improved performance in our plants.

Our Asia Pacific businesses once again contributed solid

results during the year. In Australia, net sales improved, in line with the steady growth in the detached housing market and the positive momentum in the repair and remodel market.

Our New Zealand business delivered improved results supported by a strong local housing market, particularly in Auckland and Christchurch. However, the rate of growth

slowed in comparison to the prior fiscal year. Our Philippines business continued to grow, driven by increased penetration into the growing residential high rise market and the strengthening commercial market.

We continue to invest in additional manufacturing capacity across our US and Asia Pacific segments, including capacity expansion projects at our Plant City (Florida),

Cleburne (Texas), and Carole Park (Queensland) locations. During fiscal year 2015 we spent US$173.1 million on these capacity expansion projects. We have also spent a combined US$65.8 million on the strategic purchases of our previously leased

Rosehill (New South Wales) site, and a parcel of land near our Tacoma (Washington) plant, securing our manufacturing footprints in both locations for the long term.

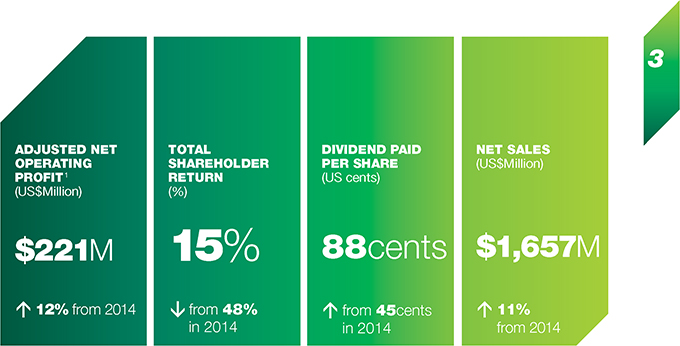

CAPITAL ALLOCATION AND SHAREHOLDER RETURNS

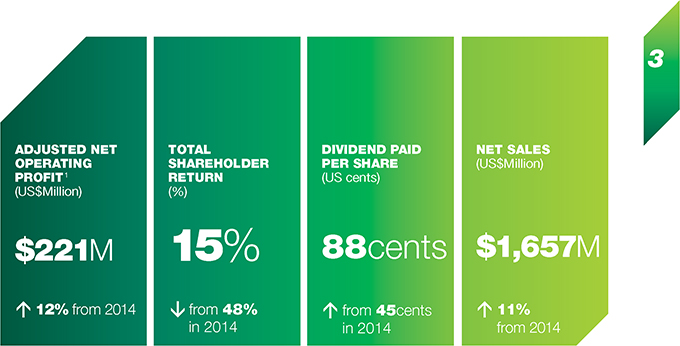

Our strong operating performance and confidence in the operating environments enabled the Board to declare a first half dividend of US8.0 cents and a second half ordinary

dividend of US27.0 cents, as well as, a special dividend of US22.0 cents per security. The resulting full year dividend paid increased to US$390.1 million, reflecting a payment

of US88.0 cents per security, compared to US$199.1 million in the prior corresponding year, reflecting a payment of US45.0

cents per security.

The ordinary dividend reflects our commitment to provide shareholder returns within the ordinary dividend payout ratio of 50 to 70% of net

operating profit, excluding asbestos adjustments. Additionally, during the first quarter of fiscal year 2015 we repurchased and cancelled 715,000 shares of our common stock.

On 21 May 2015, the Board announced a new share buyback program to acquire up to 5% of its issued capital. This share repurchase authorisation represents an

additional avenue we have taken to return capital to investors and enhance long-term shareholder value.

BOARD APPOINTMENTS

On 20 March 2015, we announced the appointment of Andrea Gisle Joosen to our Board. Andrea will stand for election at our 2015 Annual General

Meeting (AGM). Andrea has a wealth of business experience including brand building, marketing and business development across a range of business sectors.

On 15 August 2014 Russell Chenu was elected to the Board by shareholders at the 2014 AGM. Russell, who retired as

Chief Financial Officer in November 2013 after nine years with us, has substantial senior management and finance experience across a range of industries and brings a deep understanding of James Hardie.

ASBESTOS INJURIES COMPENSATION FUND (AICF)

Based on our strong operating results during fiscal year 2015, we will contribute US$62.8 million to the AICF in July 2015. This amount represents 35% of our free cash

flow for fiscal year 2015, which we are obliged to contribute as part of our commitment under the Amended and Restated Final Funding Agreement.

Collectively, we have

provided over A$1 billion towards asbestos disease related compensation, and medical research and education since 2001.

On 27 February 2015, the AICF confirmed

that the NSW government had agreed to amend the terms of the Loan Facility provided to AICF by the

NSW government. As a consequence of the amendments, it is expected that the AICF will continue to pay claims in full, as

they fall due. We acknowledge the efforts of the parties in reaching an outcome to this matter which we consider addresses the interests of all stakeholders.

ANNUAL GENERAL MEETING

This year’s AGM will be held on Friday, 14 August 2015, in Dublin, Ireland.

Shareholders can participate via a teleconference. Details regarding the matters to be acted upon at the 2015 AGM will be contained in the notice of meeting and related

materials.

Michael Hammes

Chairman

CEO’S

REPORT

DURING FISCAL YEAR 2015

WE CONTINUED TO DELIVER

STRONG OPERATING

EARNINGS, ALLOWING US

TO ACHIEVE OUR HIGHEST

EVER REVENUE RESULT

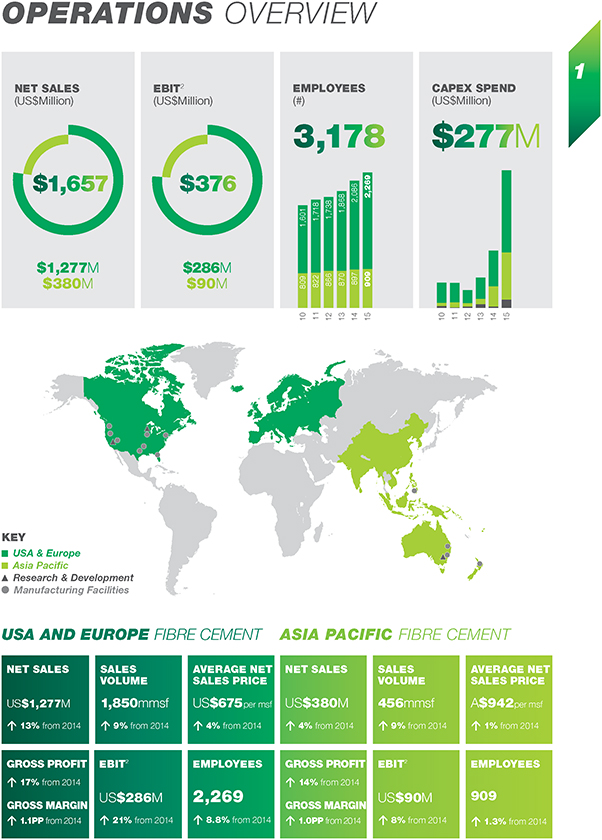

For the period group revenue increased 11% to US$1,656.9 million from US$1,493.8 million. Both the USA and Europe and

Asia Pacific segments contributed to the stronger revenue outcome.

In particular, our USA and Europe segment delivered significant earnings growth. Revenue, sales

volume, average net sales price and the Earnings Before Interest and Tax (EBIT) margin all grew compared to fiscal year 2014. This performance was driven by strong growth in our market share and a continued focus across our plants on cost management

and operational excellence.

CAPACITY EXPANSION

During fiscal year 2015, we continued to invest in the expansion of our production capacity across our US and Australian manufacturing networks. In the US, our capacity

expansion projects at Plant City and Cleburne have positioned us to capitalise on the projected recovery of the US housing market and our market share growth objectives. In Australia, our investment in capacity expansion at Carole Park and the

purchase of the land and buildings at Rosehill, have secured our manufacturing footprint in the Australian market for years to come.

The following is a list of

significant capacity expansion related projects that we invested in during fiscal year 2015:

|

|

|

|

|

| Project Description |

|

CAPEX SPEND

FY15 US$M |

|

| Plant City, Florida – 4th sheet machine and ancillary facilities |

|

|

46.4 |

|

|

|

| Cleburne, Texas – 3rd sheet machine and ancillary facilities |

|

|

24.7 |

|

|

|

| Carole Park, Queensland – capacity expansion project |

|

|

36.2 |

|

|

|

| Tacoma, Washington – land and buildings |

|

|

28.3 |

|

|

|

| Rosehill, New South Wales – land and buildings |

|

|

37.5 |

|

|

|

| Total capacity expansion spend |

|

|

173.1 |

|

MANUFACTURING

James Hardie recognises the importance of minimising our impact on the environment. Sustainable, efficient manufacturing remains critical to our success and we take

pride in continuing to develop new initiatives and sustainable practices to improve our manufacturing efficiency while also reducing our impact on the environment.

In the United States, our Peru (Illinois), Reno (Nevada), and Pulaski (Virginia) manufacturing facilities are ISO 14001 certified. ISO 14001 is a voluntary

certification issued by a third party certified auditor attesting that we have established the environmental management best practices as documented in the ISO 14001 requirements framework. These best practices include a standardised approach to

environmental training, internal auditing, record keeping and documentation, as well as continuous improvement processes from a resource conservation and energy reduction perspective.

A key aspect driving our manufacturing efficiency is the recycling of input materials. For instance, we re-introduce sludge and dust back into our manufacturing

process. Water usage forms a critical part of the fibre cement manufacturing process and is reused at least four times before it is treated and released. We continue to research new water optimisation technologies as part of a continuous effort to

reduce both the amount of fresh water used and discharged. Additionally, our plants reuse reject product as raw materials for packaging and pallets to transport our products.

Our recent capacity expansion at Plant City (Florida), Cleburne (Texas) and Carole Park (Queensland) has provided many benefits from a manufacturing efficiency stand

point and, importantly, the newly installed machines are state of the art in terms of sustainability and reducing waste.

Another benefit arising from the recent capacity expansion at Carole Park is that the plant can now manufacture, at this

site, a wider range of products including the Scyon™ advanced cement composite building product range. By significantly reducing the distance required to transport our product to distributors it minimises shipping distances and consequently

fuel consumption.

PRODUCTS

While

sustainable, efficient manufacturing processes are an integral part of James Hardie’s story, the development of industry leading, innovative, durable products and building solutions is also of critical importance.

James Hardie is the first and only Australian fibre cement manufacturer to have internal lining products certified by Good Environmental Choice Australia (GECA).

GECA’s scheme, which provides consumers with confidence that the products they choose have a lower impact on the environment and human health, is recognised by the Green Building Council of Australia.

HardieWrap™ weather barrier has also been launched in Australia following the strong sales achieved in the US. HardieWrap™ weather barrier sits behind the

cladding and delivers a triple shield of protection to help against external weather penetration, internal condensation build-up and external heat penetration.

In

the United States, the use of James Hardie products can contribute points towards the United States Green Building Council (USGBC) Leadership in Energy & Environmental Design (LEED) project certification, the National Association of Home

Builders (NAHB) National

Green Building Standard (NGBS) project certification, and many other green building rating systems. Factors contributing

to the points awarded to projects using James Hardie products include regionally-sourced raw materials, multiple manufacturing facilities spread across the country, recycled content, and low-toxicity raw materials. The NGBS also recognises the

benefits of ColorPlus® technology for removing the need for site applied finishing.

HardieBacker® board manufactured in the United States is certified by Underwriters Laboratories (UL) Environment to comply with both GREENGUARD and GREENGUARD Gold certifications. GREENGUARD Certification is

achieved when a product or material meets stringent emissions standards. GREENGUARD Gold Certification is achieved when a product or material meets even more stringent emissions standards than for GREENGUARD Certification and is specifically

designed to ensure safe environments in schools and healthcare facilities.

In April 2015, James Hardie was awarded the Greenest Siding Products Readers’

Choice Award from Green Builder Magazine. The magazine stated, “Progressive builders look to James Hardie® siding and trim for authentic design and uncompromising performance.”

COMMUNITIES

We continue to invest

heavily in our plants, people and processes. Over the past 5 years we have invested over US$500 million across our global manufacturing network. We are continuing to expand our manufacturing presence and employ many local people in the areas in

which we operate as well as being strong supporters of local businesses and suppliers.

DIVERSITY

James Hardie recognises the value of having a workforce that reflects the diverse communities and marketplaces in which we operate and serve. James Hardie believes that

a skilled and diverse workforce, which encompasses a wealth of different viewpoints, skills, attributes, life experiences and the unique strengths of each employee, contributes positively to the business performance of James Hardie.

DIVERSITY POLICY

James Hardie has

implemented a Workplace Diversity Policy that reflects a broader view of diversity than those covered by the ASX Corporate Governance Council’s recommendations

and supports certain of our core organisational values, including Operating with Respect and Building Organisational

Advantages. The policy, applies to all individuals recruited or employed by James Hardie and reflects the organisation’s inclusive view of diversity, which includes race, gender, age, national origin, religion, sexual orientation or disability.

The Board, with assistance from management, is responsible for approving and monitoring James Hardie’s diversity policy and measurable objectives in the

context of the company’s unique circumstances and industry. The Board assesses the policy and objectives annually and the organisation’s progress in achieving them.

Additional detail in regards to our diversity policy and practices can be found on our Investor Relations website

(www.ir.jameshardie.com.au) and in the Corporate Governance Statement set forth in the company’s Form 20-F annual report filing.

DIVERSITY COMPOSITION

Details of

diversity composition across various levels of the company are detailed below. The Board has a goal to achieve:

| (i) |

diversity characteristics in excess of 30% and; |

| (ii) |

women in excess of 20% among non-executive directors. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

Percentage of

female employees

as at 31 March 2015 |

|

|

Percentage of

female employees

as at 31 March 2014 |

|

|

Percentage

of employees with diversity

characteristics

as at 31 March 2015 |

|

|

Percentage

of employees with diversity

characteristics

as at 31 March 2014 |

|

| James Hardie Board 1 |

|

|

22% (2 of 9) |

|

|

|

14% (1 of 7) |

|

|

|

33% (3 of 9) |

|

|

|

29% (2 of 7) |

|

| US BUSINESS

2 |

|

| Senior leadership positions 3 |

|

|

10% (12 of 119) |

|

|

|

10% (12 of 115) |

|

|

|

26% (31 of 119) |

|

|

|

23% (26 of 115) |

|

| All management positions |

|

|

13% (41 of 306) |

|

|

|

12% (47 of 390) |

|

|

|

27% (84 of 306) |

|

|

|

25% (97 of 390) |

|

| Total workforce |

|

|

11% (236 of 2188) |

|

|

|

10% (214 of 2170) |

|

|

|

35% (757 of 2188) |

|

|

|

35% (769 of 2170) |

|

| NON-US BUSINESSES 4 |

|

| Senior leadership positions |

|

|

6% (2 of 34) |

|

|

|

3% (1 of 32) |

|

|

|

|

|

|

|

|

|

| All management positions |

|

|

11% (12 of 111) |

|

|

|

12% (15 of 130) |

|

|

|

|

|

|

|

|

|

| Total workforce |

|

|

14% (141 of 1017) |

|

|

|

13% (130 of 977) |

|

|

|

|

|

|

|

|

|

| 1 |

Includes gender and race diversity characteristics for Board. |

| 2 |

Includes gender, race and national origin diversity characteristics for US Business. |

| 3 |

Individuals at senior manager and director level and above who participate in James Hardie’s Company and Individual Performance (CIP) Plan |

| 4 |

Race/national origin diversity characteristics vary between countries and are therefore not captured in aggregate for Non-US Businesses. |

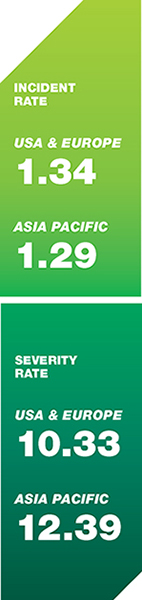

James Hardie is committed to sustaining a safe working environment and has set safety objectives that focus on:

| ¡ |

|

Achieving within our plants an incident rate of less than 2 (“incident rate” is the number of recordable incidents that occur per 100 employee manhours) and a severity rate of less than 20 (“severity

rate” is the number of days lost or restricted duty from recordable incidents per 100 employee manhours)¹ |

| ¡ |

|

Eliminating serious bodily harm |

| ¡ |

|

Achieving zero fatalities |

Recognising that the safety of employees is critical, James Hardie has made safety one of the

scorecard measures that the Board uses to determine the performance of senior executives under the company’s Long Term Incentive Plan.

USA AND EUROPE FIBRE CEMENT SAFETY PERFORMANCE

The USA and Europe fibre cement segment recorded 25 incidents in fiscal year 2015. The incident rate was 1.34 and the severity rate was 10.33.

From a safety perspective, the company’s focus in fiscal year 2015 has been:

| ¡ |

|

Further developing and refining safety expectations to align with a zero-harm culture |

| ¡ |

|

Supporting severity reduction efforts through engineering |

| ¡ |

|

Continuing with the brother’s keeper mind-set |

| ¡ |

|

Further developing leadership capability |

| ¡ |

|

Focusing on accountability to shift risk tolerance

|

Looking forward to fiscal year 2016, we will be:

| ¡ |

|

Aligning behavioural safety efforts across the global organisation |

| ¡ |

|

Continuing to focus on positive recognition for good safety performance |

| ¡ |

|

Broadening the safety culture beyond the manufacturing sector |

| ¡ |

|

Differentiating between inherent risk and accepted risk |

| ¡ |

|

Continuing to develop leadership capabilities |

| ¡ |

|

Focusing on quality and sustainability of existing systems |

ASIA PACIFIC FIBRE CEMENT SAFETY

PERFORMANCE

The Asia Pacific fibre cement segment recorded 9 incidents in fiscal year 2015. The incident rate was 1.29 and the severity rate was

12.39. The business now has achieved five consecutive years of incident and severity rates below its safety goals of “2 and 20”.

The theme for fiscal

year 2015 was ‘“promoting and challenging” – educating, enhancing and challenging norms.

Looking forward to fiscal year 2016, we will be:

| ¡ |

|

Promoting behavioural based safety focus |

| ¡ |

|

Recognising good safety performance |

| ¡ |

|

Empowering our people to STOP for safety |

| ¡ |

|

Building a risk intelligent culture |

| ¡ |

|

Developing leadership capabilities |

| ¡ |

|

Focusing on lead indicators |

| |

1 |

James Hardie’s incident and severity rates relate to factory employees and does not include our sales force, corporate or administrative employees. |

DURING JULY 2015, JAMES HARDIE WILL

CONTRIBUTE US$62.8 MILLION TO THE

ASBESTOS INJURIES COMPENSATION

FUND (AICF)

This amount represents 35% of James Hardie’s free cash flow for fiscal year 2015, which the company is obliged

to contribute as part of its commitment under the Amended and Restated Final Funding Agreement (AFFA).

As of 31 March 2015, AICF had net cash and investments

of A$28.8 million. In July 2014, James Hardie contributed US$113.0 million to the AICF.

Including its July 2015 contribution, James Hardie has provided over A$1

billion towards asbestos compensation since 2001.

James Hardie continues to contribute to medical research into the prevention, treatment and cure of asbestos

related diseases, and has more recently provided additional amounts to support clinical trials to develop a new treatment for mesothelioma.

Additionally James

Hardie is the primary supporter (and only commercial supporter) of Australia’s largest education campaign regarding the dangers of asbestos. The education campaign is aimed at educating home renovators about the risk of asbestos in the built

environment. An example of the committee’s work can be found at the website (www.asbestosawareness.com.au).

ANNUAL ACTUARIAL

ASSESSMENT

KPMG Actuarial conducts an annual actuarial assessment of the liabilities of the AICF to enable projections to be regularly updated in

line with actual claims experience and the claims outlook.

James Hardie received an updated actuarial report from KPMG Actuarial at 31 March 2015, which

showed the undiscounted and uninflated central estimate net of insurance recoveries increased from A$1.547 billion at 31 March 2014 to A$1.566 billion at 31 March 2015.

James Hardie discloses summary information on claims numbers as part of its quarterly results releases. For additional information, please see the full 2015 actuarial

report of KPMG Actuarial, which is available on our Investor Relations website (www.ir.jameshardie.com.au).