Exhibit 99.2

® James hardie DRIVING GROWTH REVIEW ANNUAL 2017

RESULTS AT A GLANCE

ADJUSTED NET NET SALES

ADJUSTED EBIT(2) ADJUSTED DILUTED OPERATING (US$Million) (US$Million) EARNINGS PER SHARE (1)

PROFIT(1) (US$Million) (US cents)

$249M $1,922M $354M 56cents

249 56 243 1,922 351 354 54 221 1,728 50 197 1,657 304 44 1,494

253 141 1,321 32 181

13 14 15 16 17 13 14 15 16 17 13 14 15 16 17 13 14 15 16 17

TOTAL US EBIT DIVIDENDS PAID ADJUSTED RETURN SHAREHOLDER MARGIN(2) PER SHARE ON CAPITAL RETURN (%) (%) (US cents) EMPLOYED (2) (%) 18% 23% 39cents 31% 48 26 88 31 31 29 23 22 21 24

35

17 58 17 43 45 22 39 18 15 13 14 15 16 17 13 14 15 16 17 13 14 15 16 17 13 14 15 16 17

Please refer to the inside back cover for full footnote references.

James Hardie is a growth Company.

We are

aggressively driving demand for and market growth of fibre cement products across all our businesses and geographies in which we operate, while actively pursuing future growth opportunities, to deliver profitable returns and create long-term

shareholder value.

JAMES HARDIE / DRIVING GROWTH

1

OPERATIONS OVERVIEW

In fiscal year 2017 we

continued to create value for our investors, customers, employees and the communities where we do business. We were able to sustain our success in this area through our significant investment in our people, plants and market development programs,

which have allowed James Hardie to maintain its position as a leader in the building materials industry.

KEY

North America International

Research & Development Manufacturing Facilities

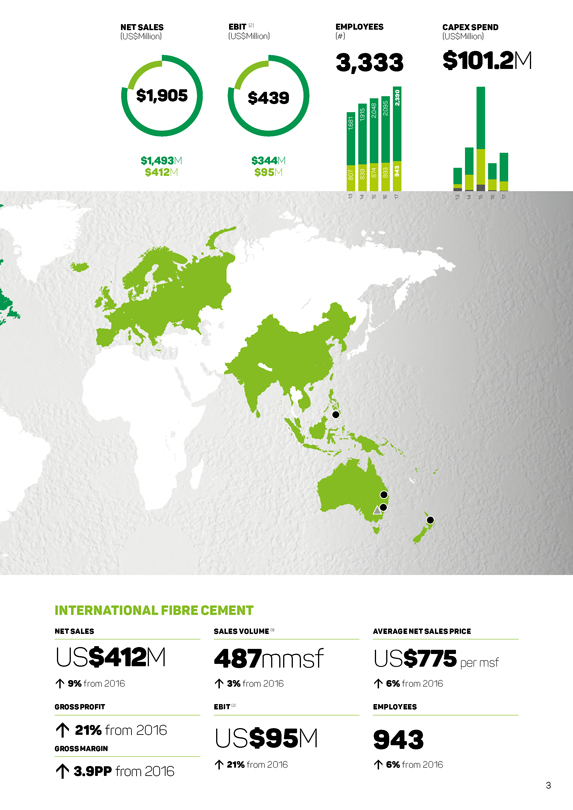

NORTH AMERICA FIBRE CEMENT

NET SALES SALES VOLUME AVERAGE NET SALES PRICE

US$1,493M 2,215mmsf US$665 per msf

U 12% from 2016 U 13% from 2016 T 1% from

2016

GROSS PROFIT EBIT (2) EMPLOYEES

U 3% from 2016 US$344M 2,390

GROSS MARGIN

T 3.1PP from 2016 T 2% from 2016 U 14% from 2016

2

NET SALES EBIT (2) EMPLOYEES CAPEX SPEND

(US$Million) (US$Million) (#) (US$Million)

3,333 $101.2M

$1,905 $439 2,390

1,915 2,048 2,095 1,681

$1,493M $344M

$412M $95M 807 839 874 893 943

13 14 15 16 17 13 14 15 16 17

INTERNATIONAL FIBRE CEMENT

NET SALES SALES VOLUME (3) AVERAGE NET SALES PRICE

US$412M 487mmsf US$775 per msf

U 9% from 2016 U 3% from 2016 U 6% from 2016

GROSS PROFIT EBIT

(2) EMPLOYEES

U 21% from 2016 US$95M 943

GROSS MARGIN

U 3.9PP from 2016 U 21% from 2016 U 6% from 2016

3

CHAIRMAN’S REPORT

NET SALES

(US$Million)

US$1,922M

U 11% from 2016

NET CASH FROM OPERATING

ACTIVITIES (US$Million)

$292M

U 12% from 2016

ADJUSTED NET OPERATING

PROFIT(1) (US$Million)

$249M

U 2% from 2016

TOTAL SHAREHOLDER

RETURN (%) T 4pp from 2016 18% It has been another significant year for James Hardie. We have made solid progress on driving our proven growth strategy, substantially invested in

our people, plants and market development programs and continued to deliver sound financial results.

The company achieved 10% volume growth and 11% revenue growth, which was ahead of expectations and was primarily driven by our North

American business. Our Australian business also contributed to this strong top line result. Our North America segment EBIT margin at 23% was within our target range of 20-25%, but below our internal

expectations. The International segment EBIT margin improved by 2.6 percentage points and was very strong at 23%. Even with some of our financial results below our internal expectations, our total shareholder returns of 18% and return on capital

employed of 31%, remain at the top of our peer group.

We are continuing to invest in building capability for long-term organic growth. During fiscal year 2017 we

invested heavily in our manufacturing network, including the start-up of four new lines across North America, the announcement of a greenfield expansion project next to our existing Tacoma (Washington) plant

and the continued addition of capacity in the Philippines. Additionally we made significant investment in our people and market development programs globally, to better position us for future growth. We are continuing to expand the breadth and depth

of our managerial talent and have recruited externally to fill positions on our executive management team. Our goal is to add to the already strong management capability in place and enhance the breadth and depth of the executive team. As an

example, Jack Truong recently joined as our President, International Operations in early April 2018 bringing with him more than three decades of experience and a unique set of skills to drive both market demand for fibre cement and our market share

in all our businesses and geographies, while being open to future growth opportunities. Additionally, we are committed to strengthening the management team beyond the executive team through a combination of recruiting to add capability and an

increased focus on development and retention of our high potential employees to ensure our management depth and capability are in place to drive our growth strategy. CAPITAL ALLOCATION AND SHAREHOLDER RETURNS We remain committed to investing in

organic growth; maintaining our ordinary dividend; and having the capacity for strategic opportunities or additional shareholder returns while maintaining a strong balance sheet.

Our underlying confidence in the strength of our businesses and the environments in which they operate enabled the Board to declare a first half dividend of US10.0 cents and a

second half ordinary dividend of US28.0 cents. The resulting full year ordinary dividend declared of US$170.0 million, reflecting a payment of US38.0 cents per security, was in-line with the full year

ordinary dividend declared and paid for fiscal year 2016 of US$169.9 million, reflecting a payment of US38.0 cents per security. The ordinary dividend reflects our commitment to provide shareholder returns within the ordinary dividend payout

ratio of 50 to 70% of net operating profit, excluding asbestos adjustments. Additionally, during the second quarter of fiscal year 2017 we returned an additional $100 million to shareholders in the form of repurchased and cancelled 6,090,133

shares of our common stock. The aggregate cost of the shares repurchased and cancelled was A$131.4million (US$99.8million), at an average market price of A$21.58 (US$16.40). Overall, the company maintains a strong balance sheet strategy and operated

within our stated leverage target of 1-2 times adjusted EBITDA. Our financial management remains consistent with an investment grade rated company. ASBESTOS INJURIES COMPENSATION FUND (AICF) Due to our strong

financial performance during fiscal year 2017, we will contribute approximately US$102.2 million to the AICF in July 2017. This amount represents 35% of our free cash flow for fiscal year 2017 which we are obliged to contribute as part of our

commitment under the Amended and Restated Final Funding Agreement. Including this contribution, we have provided over A$1.3 billion towards asbestos disease related compensation and medical research and education since 2001. ANNUAL GENERAL

MEETING This year’s AGM will be held on Tuesday, 8 August 2017, in Dublin, Ireland.

Shareholders can participate via a teleconference. Details regarding

the matters to be acted upon at the 2017 AGM will be contained in the Notice of Meeting and related materials. Michael Hammes Chairman 5

CEO’S REPORT

James Hardie is a growth

company. Our fiscal year 2017 results reflect this with the company delivering strong revenue growth and cash generation. Revenue increased by 11%, allowing us to achieve our highest ever revenue result of $1.9 billion, net cash provided from

operating activities increased by 12% and total shareholder return was strong at 18%.

6

In North America, we increased volumes and revenue driven by underlying market growth and continued improvement in our commercial execution resulting in improved market

penetration. Our North American segment EBIT was 23% and within our target range of 20-25%, but below our internal expectations. During fiscal year 2017 we significantly increased our manufacturing capacity in

North America with the addition of 4 new lines and 750 million feet of brownfield capacity that will continue to drive a high return on capital for the company. However, the capacity growth also created challenges for our North America

manufacturing network as we accelerated commissioning of new capacity and overall performance of the network lagged fiscal year 2016 performance. During fiscal year 2017 we commissioned lines at our Cleburne (Texas) and Plant City (Florida)

facilities, continued to start up both sheet machines at our Fontana (California) facility, and began work to restart our Summerville (South Carolina) facility which is on track to be commissioned in early fiscal year 2018.

In Australia, increased volumes and favourable product mix drove higher net sales. Favourable conditions in the domestic repair and remodel and single detached housing markets in

the eastern states of Australia contributed to this solid result. Similarly, the New Zealand business delivered improved results supported by growth in residential markets in the North Island. Volumes in the Philippines business were lower due to

the entrance of competitive imports during the fiscal year and the European business contributed both higher volumes and margins.

OUTLOOK

We expect the modest market growth and more prolonged recovery of the US housing market to continue into fiscal year 2018. The single family new construction market and repair and

remodel market are expected to grow similar to the year-on-year growth experienced in fiscal year 2017. We expect our North America segment sales volume growth to

outpace overall market growth and our EBIT margin to be in our stated target range of 20% to 25%. Finally, we expect to deliver improved operating performance in our manufacturing network.

Net sales from the Australian business are expected to trend in-line with the average growth of the domestic repair and remodel and single

detached housing markets in the eastern states of Australia. Similarly, the New Zealand business is expected to deliver improved results supported by growth in residential markets in the North Island. Our Philippines business was adversely impacted

by the entrance of imports from a competitor during fiscal year 2017; while the change in the overall competitive landscape is expected to persist the impact on volumes has steadied in recent periods and we expect net volume growth in fiscal year

2018.

STRATEGIC PILLARS 2017 PROGRESS

Driving profitable

growth and delivering superior returns is what we expect, and what you expect. Our ability to deliver growth and returns is underpinned by four strategic pillars. The four pillars provide a strategic framework to invest in people, market position,

our industry leading brand, and new strategic opportunities, driving growth for the next decade.

PEOPLE

We are improving our organisational capability by:

Ensuring a safe work environment

Developing and promoting our people, including building a pipeline of talent for critical roles

Attracting top external talent

Embracing a culture of engagement with our employees

Delivering a better employee retention outcome

MARKET POSITION

We are aiming to grow our market share in all our businesses and geographies by:

Growing fibre

cement as a valuable substitute for wood and vinyl siding and trim in the new construction, repair and remodel and multifamily segments

Maintaining our fibre

cement category position by delivering differentiated value from across all points of the supply chain through to the home owner

Driving an increase in our share

of the rigid backer board market, while extending our presence in the underlayment market to non-fibre cement categories and adjacent accessories

Developing an international growth strategy beyond our current business, including new geographies and new products and segments

Utilising a segmented approach to brand positioning and strategic pricing

BRAND PROMISE

We are delivering differentiated products and services by:

An unrivalled

commitment to research and development

Maintaining our manufacturing cost advantage

Delivering industry leading quality and service levels

Investing globally in future

manufacturing capability and capacity

Leveraging technology to better improve the customer experience

NON-FIBRE CEMENT

We will continue to explore

opportunities for growth beyond our existing fibre cement business by:

Investing in fibreglass protrusion technology and our existing fibreglass window frame

business

Identifying other non-fibre cement businesses within the building materials sector

Prioritising early stage technology where our existing core competencies around product innovation, process improvement and market development can add value

Giving consideration to fibre cement opportunities beyond existing geographies

SUMMARY

James Hardie is a growth company, and we are continuing to put additional capability in place. As we deliver on the strategic objectives of the four pillars we are

confident in driving growth for the next decade while delivering superior returns.

ENVIRONMENTAL, SOCIAL AND GOVERNANCE REVIEW

As a

leader in the building materials industry, James Hardie is committed to creating long-term sustainable value for everyone connected to our organisation. Our commitment to sustainability includes not only our efforts to promote efficient

manufacturing processes, but also our commitment to become a world-class safety organisation and positively impact the communities in which we operate. At James Hardie, we embrace our corporate commitment to sustainability and seek to build on our

significant progress toward these important goals.

SUSTAINABLE MANUFACTURING

We understand that

efficient and sustainable manufacturing processes are critical to our success. Many of our customers require that their product suppliers retain an ISO 14001 certification, a voluntary accreditation process in which the International Organization

for Standardization certifies that a party has met certain substantive qualifications that signify excellence in environmental management. Three of our largest facilities continue to maintain this globally recognised external certification and all

of our manufacturing locations implement ISO 14001 best practices in compliance with our global environmental policy, a copy of which is available on our Investor Relations website (www.ir.jameshardie.com.au). Programs focusing on manufacturing

sustainability include:

Resource Conservation and Waste Minimisation

Initiatives within our US and Asia Pacific operations include enhanced water reuse and raw material recycling efforts, as well as retrofitting the lighting in our

manufacturing facilities with new, highly energy efficient LED lights and the piloting of solar panels at our Carole Park facility.

Raw Materials We continue to

source the majority of the raw materials used in our manufacturing process from local or regional suppliers in close proximity to our manufacturing facilities, reducing the distance travelled in the procurement of such materials. This consideration

is also incorporated into our long-term planning when identifying future manufacturing locations.

Transportation Footprint Our manufacturing facilities are

strategically located in those areas of the world nearest to our key markets, minimising the overall shipping distances of our products.

Emissions Reductions We

have implemented effective environmental control systems at each facility worldwide, reducing our overall emissions profile.

ENVIRONMENTAL, GOVERNANCE REVIEW SOCIAL CONTINUED AND

WORKPLACE SAFETY

We are committed to providing a safe working environment for all of our

employees and have sustained incident rates well below industry average for the past decade. For fiscal year 2017, our global incident and Days Away, Restricted or Transferred (DART) rates were 1.4 and 0.7, respectively, compared to 3.8 and 1.0, for

all manufacturing industries. During fiscal year 2017, our focus shifted from lagging to leading indicators in our pursuit of a Zero-Harm Culture, recognising that any one incident that results in physical harm to an employee is one too many. In

2016, as part of this advanced approach, we established a Safety Culture Steering Committee in the United States comprised of hourly and salaried leaders representing each manufacturing location. The Committee’s primary objective has been to

take the next step in our development toward becoming a company that is identified as having a best-in-class safety culture. Taking a long-term approach, the Committee

has started by identifying both current factors that forestall the company’s progression toward zero-harm, as well as best practices capable of driving improvement of safety performance within our

organisation. The Committee collaborated with North American, European and Asia Pacific operational teams to develop a new global safety vision for James Hardie:

To become a World-Class Safety Organisation focused on Safe People, Safe Plants, and Safe Systems to drive a Zero-Harm Culture

The Safety Culture Steering Committee developed and our executive leadership adopted a multi-year plan on how to achieve our goal of achieving a Zero-Harm Culture. As such, the

emphasis has been placed on:

Engaging, empowering and training Safe People through visible leadership support and a commitment to safety that is evident 24/7/365

Cleaning and organising Safe Plants through a structured housekeeping approach and provide improvements that promote sustainable housekeeping processes at each

facility

Developing Safe Systems that provide real-time data and tools for continuous risk reduction

SOCIAL RESPONSIBILITY

“Operate with

Respect” is a core value at James Hardie globally and reflected in our approach to Social Responsibility. Through our Charitable Program, we seek to have a positive social impact in the communities where we operate and in our markets by

actively participating in charitable and humanitarian activities and projects. Every employee and each of our facilities is encouraged to support local charitable efforts that align with the company’s dual vision of meeting the basic needs of at-risk individuals and families, by helping them gain stability and become self-sufficient and enhancing a community’s vitality through the support of organisations that

serve our communities or create and foster economic and environmental vitality. Our commitment can be in the form of matching financial gifts made and time volunteered by our employees, as well as through the donation of James Hardie products.

In fiscal year 2017, the company and its employees contributed nearly $3,000,000 in monetary and product donations to 67 organisations in the United States

including:

Habitat For Humanity, a global non-profit housing organisation working in nearly 1,400 communities across the

United States and in approximately 70 countries around the world.

Cope Environmental Center, an organisation located in Centerville, Indiana that educates

thousands of kids a year through its school and nature programs, received donated product that was installed on the organisation’s new Kid’s Nature Center where children of all ages can learn about different aspects of environmental

science.

Calgary Homeless Foundation, an organisation located in Calgary, Alberta in Canada that works with the local community to provide the resources and

infrastructure necessary to meet the needs of the homeless community, received donated product that was installed on area homes that re-house members of the local homeless community.

Happy Hallow Children’s Camp, an organisation located in Central Indiana that provides disadvantaged children the opportunity to spend time away from the city in a natural

setting to develop self-sufficiency skills, received donated product for their 60-year old main cabin.

Queretaro Institute for Children, an organisation located in Laredo, Texas that provides early education programs for local low-income pre-school children between the ages 3 and 6, received donated product for a new pre-school.

World Vision, we continued to support the organisation with product donations needed to restore the homes of individuals in communities impacted by the floods in the Pacific

Northwest and Virginia.

Lower Nine Organisation a community group that represents New Orleans’ Ninth Ward, which is still recovering from the devastation

caused by Hurricane Katrina, continues to receive donated product from James Hardie for home restorations.

In addition, we continue to participate in projects

supporting our disabled and homeless veterans.

ENVIRONMENTAL MANAGEMENT PRINCIPLES

We maintain a comprehensive environmental management system that is consistent with our stated environmental policy and designed to help reduce our global environmental impact.

Whenever possible, we seek to use renewable and recyclable resources, practice appropriate conservation techniques and take steps to protect the environment against pollution. For example, water usage forms a critical part of the fibre cement

manufacturing process and is reused at least four times before being treated and released. During fiscal year 2017, we have undertaken efforts to enhance water reuse by partnering with local business that can further reuse waste water produced

during our manufacturing process.

In addition we continue to successfully reintroduce raw material components back into our process and have developed resource

applications for our by-products for use in the manufacture of cement and road based products. Our goal is to continuously improve the effective use of natural resources and energy efficiency of our operations

by setting objectives, targets, and programs for improvement.

We are also committed to reporting and tracking our carbon footprint through voluntary participation

in the globally recognised Carbon Disclosure Project (CDP). Participation in the CDP will allow us to track our progress on key environmental indicators such as manufacturing and transportation related carbon reduction efforts and energy efficiency.

Other initiatives in the coming fiscal year include a transition to the new ISO14001-2015 certification standard and the selection and implementation of a new Environmental Health and Safety (EHS) Management System platform which will enhance our

ability to track key EHS metrics on a real-time basis.

11

ASBESTOS FUNDING

During July 2017, James Hardie

will contribute approximately US$102.2 million to the Asbestos Injuries Compensation Fund (AICF).

This amount represents 35% of James Hardie’s free cash

flow for fiscal year 2017, which the company is obliged to contribute as part of its commitment under the Amended and Restated Final Funding Agreement (AFFA).

Including its July 2017 contribution, James Hardie has provided over A$1.3 billion towards asbestos compensation and medical research and education since

2001.

James Hardie continues to contribute to medical research through the Asbestos Diseases Research Foundation (ADRF) which was established in 2006 as a

charitable, not-for-profit organisation dedicated to assist and support the research efforts into asbestos and other dust-related diseases. The Foundation established

and operates the Asbestos Diseases Research Institute (ADRI) a dedicated research institute. More information regarding the ADRI can be obtained on their website (www.adri.org.au).

Additionally James Hardie is the primary supporter (and only commercial supporter) of Australia’s largest educational campaign regarding the dangers of asbestos. The

educational campaign is aimed at educating home renovators about the risk of asbestos in the built environment. An example of the Asbestos Education Committee’s work can be found on their website (www.asbestosawareness.com.au).

ANNUAL ACTUARIAL ASSESSMENT

KPMG Actuarial conducts an annual actuarial assessment of the

liabilities of the AICF to enable projections to be regularly updated in line with actual claims experience and the claims outlook.

James Hardie received an

updated actuarial report from KPMG Actuarial at 31 March 2017, which showed the undiscounted and uninflated central estimate net of insurance recoveries decreased from A$1.434 billion at 31 March 2016 to A$1.386 billion at

31 March 2017.

James Hardie discloses summary information on claims numbers as part of its quarterly results releases. For additional information, please see

the full 2017 actuarial report of KPMG Actuarial, which is available on our Investor Relations website (www.ir.jameshardie.com.au).

CORPORATE HEADQUARTERS Europa House, Second Floor Harcourt Centre Harcourt Street, Dublin 2, Ireland Telephone +353 1 411 6924 Facsimile +353 1 479 1128 KEY DATES 31 March End of James Hardie Industries plc Fiscal Year 2017 18 May FY17 Quarter 4 and Full Year results and management presentation 19 May Annual Review released 6 August Voting Instruction Forms close 9.45am (Dublin time) / 6.45pm (Sydney time) for Annual General Meeting 8 August Annual General Meeting, Dublin 8 August FY18 Quarter 1 results and management presentation 9 November FY18 Quarter 2 and Half Year results and management presentation ANNUAL GENERAL MEETING (AGM) The 2017 AGM of James Hardie Industries plc will be held in Dublin, Ireland, at 6.45am Dublin time, on Tuesday, 8 August 2017. The AGM will be broadcast via a teleconference at 3.45pm AEST. Further details will be set out in the Notice of Annual General Meeting 2017. SHARE/CUFS REGISTRY James Hardie Industries plc’s registry is managed by Computershare. All enquiries and correspondence regarding holdings should be directed to: Computershare Investor Services Pty Ltd Level 5, 115 Grenfell Street Adelaide SA 5000 Or GPO Box 2975 Melbourne VIC 3001 Telephone within Australia: 1300 556 161 Telephone outside Australia: +61 (0) 3 9415 4000 Website: www.computershare.com James Hardie Industries plc (ARBN 097 829 895) Incorporated in Ireland with its registered office at Europa House, Second Floor, Harcourt Centre, Harcourt Street, Dublin 2, Ireland and registered number 485719. The liability of its members is limited. ™ or ® denotes a trademark or Registered mark owned by James Hardie Technology Ltd. ©2017. James Hardie Industries plc. FORWARD-LOOKING STATEMENTS Certain statements in this Annual Review may constitute “forward-looking statements” as defined in the Private Securities Litigation Reform Act of 1995. James Hardie uses such words as “believe,” “anticipate,” “plan,” “expect,” “intend,” “target,”, “estimate,” “project,” “predict,” “forecast,” “guideline,” “aim,” “will,” “should,” “likely,” “continue,” “may,” “objective,” “outlook,” and similar expressions are intended to identify forward-looking statements but are not the exclusive means of identifying such statements. Readers are cautioned not to place undue reliance on these forward-looking statements and all such forward-looking statements are qualified in their entirety by reference to the following cautionary statements. Forward-looking statements are based on James Hardie’s current expectations, estimates and assumptions and because forward-looking statements address future results, events and conditions, they, by their very nature, involve inherent risks and uncertainties, many of which are unforeseeable and beyond the company’s control. Many factors could cause the actual results, performance or achievements of James Hardie to be materially different from those expressed or implied in this Annual Review, including, among others, the risks and uncertainties set forth in Section 3 “Risk Factors” in James Hardie’s Annual Report on Form 20-F for the year ended 31 March 2017; changes in general economic, political, governmental and business conditions globally and in the countries in which James Hardie does business; changes in interest rates, changes in inflation rates; changes in exchange rates; the level of construction generally; changes in cement demand and prices; changes in raw material and energy prices; changes in business strategy and various other factors. Should one or more of these risks or uncertainties materialise, or should underlying assumptions prove incorrect, actual results may vary materially from those described herein. These forward-looking statements are made as of the date of this Annual Review and James Hardie does not assume any obligation to update them, except as required by law. Investors are encouraged to review James Hardie’s Annual Report on Form 20-F, and specifically the risk factors discussed therein, as it contains important disclosures regarding the risks attendant to investing in our securities. NON-GAAP FINANCIAL INFORMATION This Annual Review contains financial measures that are not considered a measure of financial performance under US GAAP and should not be considered to be more meaningful than the equivalent US GAAP measure. Management has included such measures to provide investors with an alternative method for assessing its operating results in a manner that is focused on the performance of its ongoing operations. Additionally, management uses such non-GAAP financial measures for the same purposes. However, these non-GAAP financial measures are not prepared in accordance with US GAAP, may not be reported by all of James Hardie’s competitors and may not be directly comparable to similarly titled measures of James Hardie’s competitors due to potential differences in the exact method of calculation. For additional information regarding the non-GAAP financial measures presented in this Annual Review, including a reconciliation of each non-GAAP financial measure to the equivalent US GAAP measure, see the sections titled “Definition and Other Terms” and “Non-US GAAP Financial Measures” included in James Hardie’s Management’s Analysis of Results for the fourth quarter and twelve months ended 31 March 2017. FINANCIAL FOOTNOTES (1) Unless otherwise stated for fiscal years 2017, 2016, 2015, 2014, 2013, 2012 and 2011 Adjusted Net Operating Profit graphs and editorial comments throughout this report refer to results from operations that may exclude asbestos, asset impairments, ASIC expenses, New Zealand weathertightness claims, non-recurring stamp duty and/or tax adjustments. (2) Unless otherwise stated for fiscal years 2017, 2016, 2015, 2014, 2013, 2012, and 2011 Adjusted EBIT graphs and editorial comments throughout this report refer to EBIT that may exclude asbestos, asset impairments, ASIC expenses, non-recurring stamp duty and/or New Zealand weathertightness claims. (3) Excludes Australian Pipes business sold in the first quarter of fiscal year 2016. (4) For fiscal year 2017 the reporting segments were to changed North America Fibre Cement and International Fibre Cement. The North America Fibre Cement segment includes North America Fibre Cement businesses only (previously it included North America Fibre Cement, Europe Fibre Cement and certain non-fibre cement manufacturing and sales activities in North America) and the International Fibre cement segment includes our Fibre Cement businesses in Australia, New Zealand, Philippines and Europe (previously it included Australia, New Zealand and the Philippines).

WWW.JAMESHARDIE.COM

James hardie

®